[caption id="attachment_1003728387" align="aligncenter" width="476"]

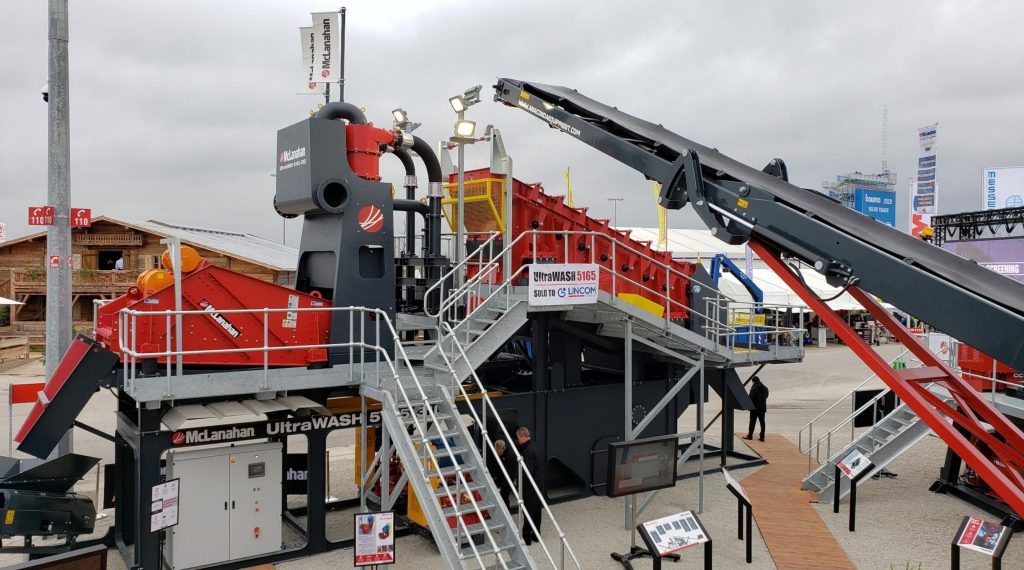

McLanahan introduced its modular UltraWASH at bauma 2019.

McLanahan introduced its modular UltraWASH at bauma 2019.[/caption]

PENNSYLVANIA – For more than 180 years, McLanahan has been designing and manufacturing washing and crushing equipment. Now, they are putting their proven, well-established solutions into modular, containerized systems shown to the market for the first time at bauma 2019. Both the UltraWASH modular wash plant and the UltraCRUSH modular cone crusher were on display.

The UltraWASH is capable of making three aggregate and two sand products while accepting capacities up to 365 t/h. It has both a single process water feed point and a single effluent discharge point. The modular design is containerized, leading to a compact footprint.

All modular systems from McLanahan come pre-wired and pre-plumbed for rapid on-site deployment or relocation. They are available in a variety of configurations, including double washing and prewashing, and come with fully integrated controls with remote operation.

For the UltraWASH, specifically, the system includes several features to simplify maintenance and maximize production. The underpan of the sizing screen features a patent pending fines forward slide. This steel tray spans the width of the bottom deck of the sizing screen and facilitates the diversion of a proportion of raw fines into the coarse sand processing stream to help balance downstream equipment and optimize plant capacity. It also permits the alterations of the proportions of fine and coarse deck areas above while precluding entry of coarse material into the fines processing stream.

A patent pending EZE-Riser lifting pedal and locking mechanism allows for simplified feed pipe disconnection and the needed clearance for pump removal when maintenance is required. The pumps can then roll out easily onto the pump trolley system, which for additional clearance for easier access during maintenance.

Thanks to McLanahan’s recent acquisition of Anaconda Equipment, the UltraWASH feed hopper and conveyor can be upgraded with the addition of tracks for easier conveyor maintenance.

The UltraWASH line is available with several configurations and add-ons including:

- Feed preparation – log washers, blade mills, screw washers

- Attritioning

- Organics removal

- Water treatment – filter presses and thickeners

Additionally, material can be sized to meet specific requirements using the line of UltraCRUSH equipment. The UltraCRUSH modular cone crusher is also containerized, easy to set up and install, and can be transported around the site or to other locations as needed.

The UltraCRUSH modular cone crusher is manufactured with a heavy duty cast steel base frame and includes replaceable base frame wear liners. It features a rotating bowl for even liner wear, a bronze inner and outer eccentric bushings for more load carrying capability, and a large, unobstructed feed opening. A hydro-pneumatic tramp iron relief system reduces wear on the crusher in the event an uncrushable material enters the crushing chamber.

For more information about McLanahan modular washing and crushing equipment, visit

www.McLanahan.com.

McLanahan introduced its modular UltraWASH at bauma 2019.[/caption]

PENNSYLVANIA – For more than 180 years, McLanahan has been designing and manufacturing washing and crushing equipment. Now, they are putting their proven, well-established solutions into modular, containerized systems shown to the market for the first time at bauma 2019. Both the UltraWASH modular wash plant and the UltraCRUSH modular cone crusher were on display.

The UltraWASH is capable of making three aggregate and two sand products while accepting capacities up to 365 t/h. It has both a single process water feed point and a single effluent discharge point. The modular design is containerized, leading to a compact footprint.

All modular systems from McLanahan come pre-wired and pre-plumbed for rapid on-site deployment or relocation. They are available in a variety of configurations, including double washing and prewashing, and come with fully integrated controls with remote operation.

For the UltraWASH, specifically, the system includes several features to simplify maintenance and maximize production. The underpan of the sizing screen features a patent pending fines forward slide. This steel tray spans the width of the bottom deck of the sizing screen and facilitates the diversion of a proportion of raw fines into the coarse sand processing stream to help balance downstream equipment and optimize plant capacity. It also permits the alterations of the proportions of fine and coarse deck areas above while precluding entry of coarse material into the fines processing stream.

A patent pending EZE-Riser lifting pedal and locking mechanism allows for simplified feed pipe disconnection and the needed clearance for pump removal when maintenance is required. The pumps can then roll out easily onto the pump trolley system, which for additional clearance for easier access during maintenance.

Thanks to McLanahan’s recent acquisition of Anaconda Equipment, the UltraWASH feed hopper and conveyor can be upgraded with the addition of tracks for easier conveyor maintenance.

The UltraWASH line is available with several configurations and add-ons including:

McLanahan introduced its modular UltraWASH at bauma 2019.[/caption]

PENNSYLVANIA – For more than 180 years, McLanahan has been designing and manufacturing washing and crushing equipment. Now, they are putting their proven, well-established solutions into modular, containerized systems shown to the market for the first time at bauma 2019. Both the UltraWASH modular wash plant and the UltraCRUSH modular cone crusher were on display.

The UltraWASH is capable of making three aggregate and two sand products while accepting capacities up to 365 t/h. It has both a single process water feed point and a single effluent discharge point. The modular design is containerized, leading to a compact footprint.

All modular systems from McLanahan come pre-wired and pre-plumbed for rapid on-site deployment or relocation. They are available in a variety of configurations, including double washing and prewashing, and come with fully integrated controls with remote operation.

For the UltraWASH, specifically, the system includes several features to simplify maintenance and maximize production. The underpan of the sizing screen features a patent pending fines forward slide. This steel tray spans the width of the bottom deck of the sizing screen and facilitates the diversion of a proportion of raw fines into the coarse sand processing stream to help balance downstream equipment and optimize plant capacity. It also permits the alterations of the proportions of fine and coarse deck areas above while precluding entry of coarse material into the fines processing stream.

A patent pending EZE-Riser lifting pedal and locking mechanism allows for simplified feed pipe disconnection and the needed clearance for pump removal when maintenance is required. The pumps can then roll out easily onto the pump trolley system, which for additional clearance for easier access during maintenance.

Thanks to McLanahan’s recent acquisition of Anaconda Equipment, the UltraWASH feed hopper and conveyor can be upgraded with the addition of tracks for easier conveyor maintenance.

The UltraWASH line is available with several configurations and add-ons including:

Comments