SUDBURY, ON – The

Ultra-Deep Mining Network (UDMN) held its second annual Symposium for its 76 network members from across Canada and announced the first of many UDMN commercial successes by one of its members,

Maestro Mine Ventilation.

Maestro was presented with UDMN’s Outstanding Achievement in Commercialization award for a technical innovation which ensures the safety of underground miners. The rapid commercial sale of this product to some of the deepest mines in the world is a testament that Maestro’s efforts combined with UDMN funding and guidance can in fact bring technology faster to market which in turn benefits the mining industry and Canadians.

[caption id="attachment_1003716216" align="alignright" width="300"]

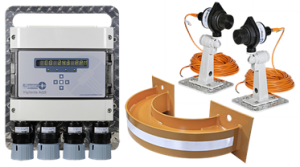

Maestro’s reliable underground gas sensors are already installed at 20 deep mines in Canada and the world.

Maestro’s reliable underground gas sensors are already installed at 20 deep mines in Canada and the world.[/caption]

Underground mines have challenging environmental conditions that include toxic gases from the drill and blast operation or gases given off by the surrounding strata rock. Protecting miners from acute or chronic gas with potential detrimental health conditions is paramount for any responsible mining company. To achieve this, a variety of sensors are required to transmit real time data from the underground workings to the surface control rooms. By using this technology, miners are able to return safely to their working areas quicker allowing significant productivity increases. However, these sensors require frequent maintenance and calibration in order to maintain accurate measurements. The previous technology required underground calibrations at each individual location using test gases. Several physical and environmental challenges prevented an accurate and repeatable calibration.

Maestro, with the support of the UDMN, has tackled this real-life application by designing and developing a digital gas sensor that can be calibrated on surface in a stable controlled environment. The digital sensors then can be “hot swapped” by a ventilation technician without the requirement of any sort of underground calibration.

Built upon the IoT (Internet of Things), the digital sensors have a complete suite of diagnostics to help determine the health of the complete system and provide maximum system uptime.

“This innovation has allowed our Vigilante AQS™ environmental stations to be installed in some of the deepest mines on the planet,” states Michael Gribbons, vice-president of Maestro. “Prior to this innovation, the underground miners lacked the confidence of the gas readings since there was no practical method of calibrating the sensors or understanding if the sensors were even working. The IoT digital sensors allow this to become a reality. This will result in major productivity improvements by getting the miners safely back to the face quicker.”

Maestro’s digital IoT gas sensors are already in use at over 20 mines since the project has started. Please see

www.MaestroVentilation.com for more information.

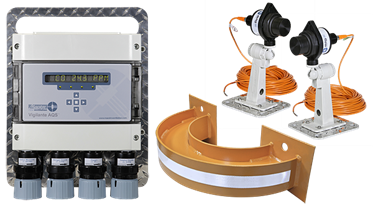

Maestro’s reliable underground gas sensors are already installed at 20 deep mines in Canada and the world.[/caption]

Underground mines have challenging environmental conditions that include toxic gases from the drill and blast operation or gases given off by the surrounding strata rock. Protecting miners from acute or chronic gas with potential detrimental health conditions is paramount for any responsible mining company. To achieve this, a variety of sensors are required to transmit real time data from the underground workings to the surface control rooms. By using this technology, miners are able to return safely to their working areas quicker allowing significant productivity increases. However, these sensors require frequent maintenance and calibration in order to maintain accurate measurements. The previous technology required underground calibrations at each individual location using test gases. Several physical and environmental challenges prevented an accurate and repeatable calibration.

Maestro, with the support of the UDMN, has tackled this real-life application by designing and developing a digital gas sensor that can be calibrated on surface in a stable controlled environment. The digital sensors then can be “hot swapped” by a ventilation technician without the requirement of any sort of underground calibration.

Built upon the IoT (Internet of Things), the digital sensors have a complete suite of diagnostics to help determine the health of the complete system and provide maximum system uptime.

“This innovation has allowed our Vigilante AQS™ environmental stations to be installed in some of the deepest mines on the planet,” states Michael Gribbons, vice-president of Maestro. “Prior to this innovation, the underground miners lacked the confidence of the gas readings since there was no practical method of calibrating the sensors or understanding if the sensors were even working. The IoT digital sensors allow this to become a reality. This will result in major productivity improvements by getting the miners safely back to the face quicker.”

Maestro’s digital IoT gas sensors are already in use at over 20 mines since the project has started. Please see

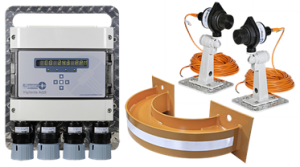

Maestro’s reliable underground gas sensors are already installed at 20 deep mines in Canada and the world.[/caption]

Underground mines have challenging environmental conditions that include toxic gases from the drill and blast operation or gases given off by the surrounding strata rock. Protecting miners from acute or chronic gas with potential detrimental health conditions is paramount for any responsible mining company. To achieve this, a variety of sensors are required to transmit real time data from the underground workings to the surface control rooms. By using this technology, miners are able to return safely to their working areas quicker allowing significant productivity increases. However, these sensors require frequent maintenance and calibration in order to maintain accurate measurements. The previous technology required underground calibrations at each individual location using test gases. Several physical and environmental challenges prevented an accurate and repeatable calibration.

Maestro, with the support of the UDMN, has tackled this real-life application by designing and developing a digital gas sensor that can be calibrated on surface in a stable controlled environment. The digital sensors then can be “hot swapped” by a ventilation technician without the requirement of any sort of underground calibration.

Built upon the IoT (Internet of Things), the digital sensors have a complete suite of diagnostics to help determine the health of the complete system and provide maximum system uptime.

“This innovation has allowed our Vigilante AQS™ environmental stations to be installed in some of the deepest mines on the planet,” states Michael Gribbons, vice-president of Maestro. “Prior to this innovation, the underground miners lacked the confidence of the gas readings since there was no practical method of calibrating the sensors or understanding if the sensors were even working. The IoT digital sensors allow this to become a reality. This will result in major productivity improvements by getting the miners safely back to the face quicker.”

Maestro’s digital IoT gas sensors are already in use at over 20 mines since the project has started. Please see

Comments