Ucore’s REE separation demo plant on track for Q4 commissioning

Ucore Rare Metals (TSXV: UCU; OTC: UURAF) has made "significant strides" in the procurement and construction process of its commercial demonstration plant for testing the RapidSX rare earth element (REE) separation technology developed by Innovation Metals (IMC). The facility is on track for commissioning in the fourth quarter of this year.

The test work, which is taking place at Ucore and IMC's laboratory partner Kingston Process Metallurgy's facility in Kingston, Ont., is part of Ucore's strategic metals complex (SMC) technology deployment process. The program was enhanced after Ucore received an independent evaluation of the RapidSX REE technology, leading to a near tripled increase in scope of the demonstration plant in July. Since then, most of the required equipment and components have been procured, as have the initial heavy and light REE feedstocks.

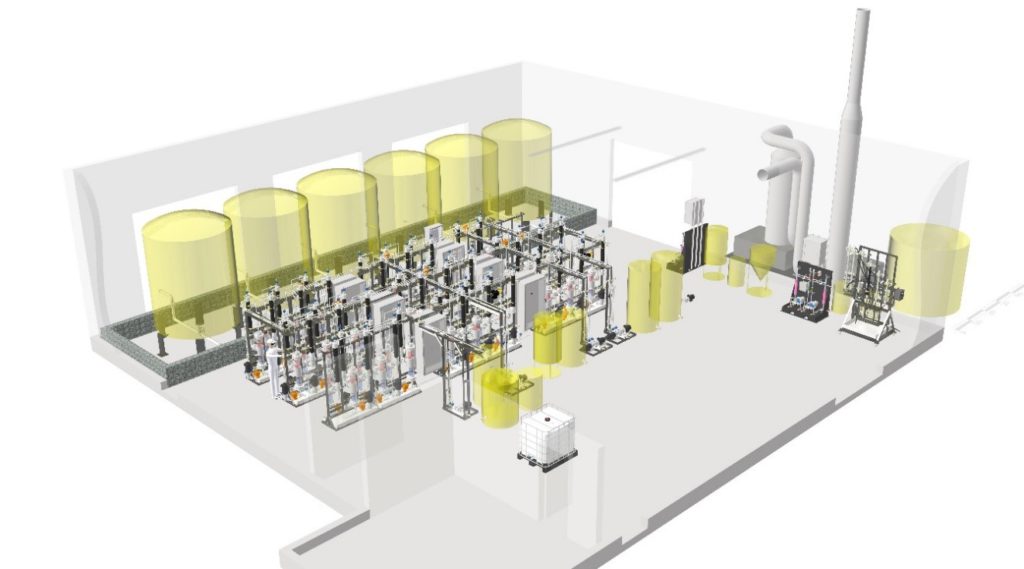

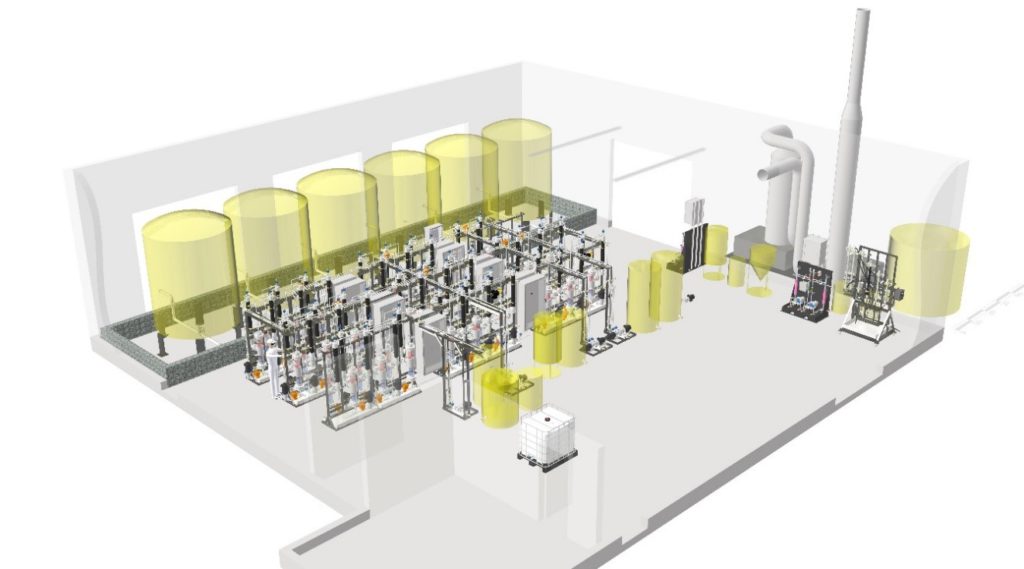

The final engineered layout of the demo plant takes up nearly all of the 465-m2 facility at KPM. The concept of building a plant within an existing building is the go-forward transition template for the engineering process that the commercialization team will replicate to create the first full-scale SMC, once the brownfield site selection process is finalized. This initial SMC is scheduled to produce 2,000 tonnes of total rare earth oxides (TREOs) by the end of 2024 and 5,000 tonnes by 2026.

“This process will demonstrate the unprecedented North American separation of tonnes of both heavy and light rare earth elements. It will then continue with end-user qualification trials throughout 2023 for Western entities seeking diversified and sustainable metallic supply chains as Ucore transitions to full-scale commercial mode with the construction of our first SMC," stated Mike Schrider, Ucore’s VP and COO.

The REE separation demo plant is capable of processing all RapidSX splits required to produce individual elements of praseodymium, neodymium, terbium and dysprosium. It would have a parallel 51-stage conventional solvent extraction (CSX) mixer-settler circuit that will match the RapidSX process configuration and enable direct head-to-head comparison of their performances. Once in commercial operation, this would be one of the first modern technology platforms for separating HREEs and LREEs as a replacement for CSX.

For more information, visit: www.ucore.com.

Comments