Ucore Rare Metals expands REE demonstration plant in Ontario

Ucore Rare Metals (TSXV: UCU; OTC: UURAF) has provided an update on the commercialization of its RapidSX rare earth element (REE) separation technology platform. The work is taking place at the Kinston Process Metallurgy (KPM) facility in Kingston, Ont.

RapidSX is a proprietary technology developed by Innovation Metals (IMC), now a subsidiary of Ucore after its acquisition in 2020. Ucore plans to commercialize and adopt the REE technology for its proposed strategic metals complex (SMC) in Alaska, which comprises a separation and purification plant for the production of rare earth oxides from the company's Bokan-Dotson Ridge REE project.

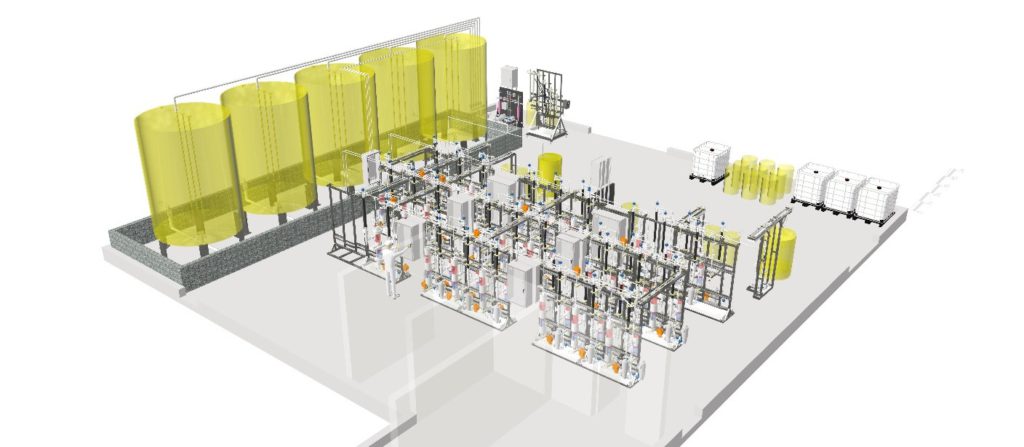

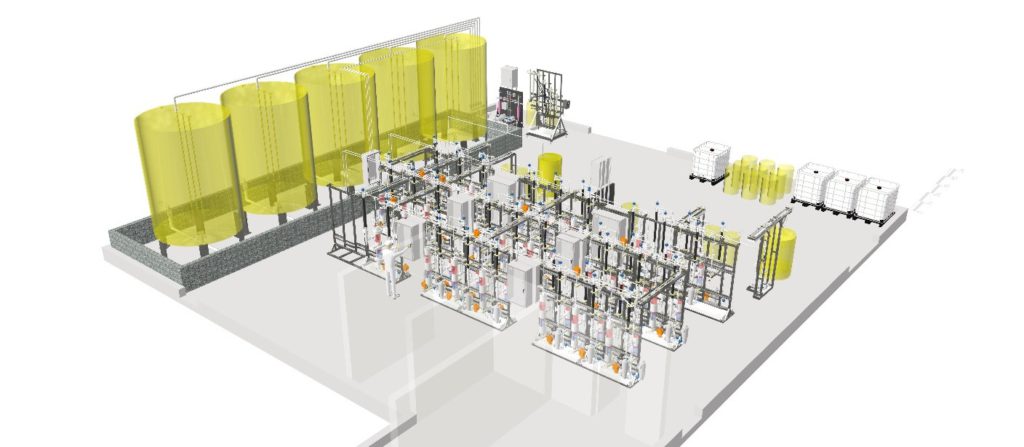

Since the last update on Dec. 29, 2021, the Ucore, Innovation Metals and Kingston Process metallurgy commercialization team has continued to assess and develop the RapidSX platform at the commercialization and development facility. The critical component in this process is the design and construction of the RapidSX REE demonstration-scale plant that will reside within the 454 m3 facility.

By the end of the first quarter of 2022, the team had planned, designed and ordered equipment to construct an 18-stage RapidSX REE demo plant, that will undergo incremental expansions to meet the broader commercial objectives of the program throughout 2022 and 2023. However, in early 2022, Ucore received very positive results from the independent RapidSX technology evaluation, including the conclusion that a RapidSX production plant can potentially have a two-thirds smaller footprint than a conventional solvent extraction with the same throughput.

The team then met with and received the buy-in from all program stakeholders to expand the design and construction of the demo plant to 51 stages, which would allow it to process many feedstock sources, including planned light and heavy REE feedstocks, and tens of tonnes of mixed rare earth concentrate on a yearly basis.

"IMC's solvent extraction process, RapidSX, has different components that allow us to "westernize" this standard chemical process so that technology risk is eliminated while in compliance with North American environmental and worker safety standards. The cellular design is scalable and allows for rapid production capacity expansion in a safe and responsible manner," said Dr. Boyd Davis, a principal of KPM.

"Ucore is in the unique position of having access to one of the world's most advanced and efficient solvent extraction-based REE separation technologies," stated Mike Schrider, Ucore's VP and COO. "RapidSX will be at a TRL (Technology Readiness Level, NASA) 6/7 once the demo plant is commissioned this fall. The logical pathway was to expand the facility now so that we are ready to make the leap to commercialization within the strategic metals complexes by early next year, along with the benefit of starting product qualification trials with our growing list of potential North American customers."

The team is now working with Ucore's upstream SMC feedstock suppliers and is planning demo plant product qualification trials to commence in the fourth quarter of 2022 with prospective North American metal and/or alloy makers and original equipment manufacturers.

For more information, visit: www.ucore.com.

Comments