Tips from Martin Engineering to control conveyor belt dust at the source

The conveyor technology experts at Martin Engineering are responding to the U.S. Mining Safety and Health Administration’s (MSHA) new dust emissions final rule by offering simple, sensible solutions for staying compliant. Often, these rule changes cause a ripple effect internationally and serve as a template for similar policies worldwide.

The engineers at Martin have dedicated years to reducing conveyor-borne dust by designing accessories and engineered solutions that improve workplace safety and production efficiency. In this article, Martin Engineering experts offer field-tested advice and methods that have delivered measurable results for mines and bulk handlers around the world for decades.

MSHA mandates operators seek to install or repair equipment that offer engineering controls which control or eliminate sources of dust. This is supplemented with administrative controls (signs, policies, etc.). Temporary personal protective equipment (PPE) is also required for exposures above the PEL but is not considered a long-term solution.

Conveyor belt dust is largely generated at the loading and discharge zones. Passive dust reduction means no machinery or electricity such as air cleaners, pumps or HAVC are needed. Passive dust reduction strategies include enclosed transfer points, shorter or sloped loading, belt training, and preventing sag between idlers.

Lowering belt speeds is an option, but that may mean increasing belt width to maintain the volume of the system. However, some material can benefit from slower speed, for instance loads with aeration fluidity, those with degradable size breakdown, dusty material, or very light and fluffy material loads.

Similar to turbulent air caused by impact, at a critical speed, bulk material moving over idlers loses contact with the belt at the idler and is launched into the air, falling back onto the belt at a slightly lower speed and releasing dust. Keeping the belt sag to 1% between idlers is a frequent specification.

Idler spacing is critical to controlling belt sag. To reduce gaps where spillage and emissions can escape and retain an even belt profile in the loading zone, idlers should be placed as closely together as possible.

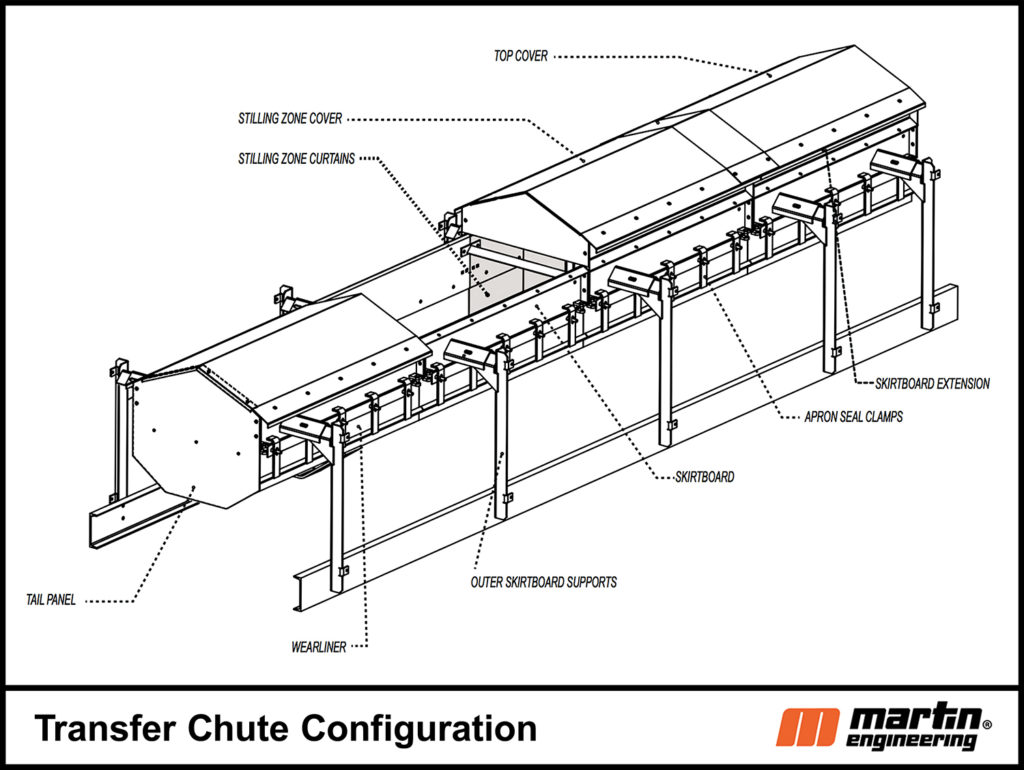

Best practice is to enclose the system

The amount of dust that can become airborne is directly proportional to the volume and speed of the airflow through the transfer point. A useful dust control strategy is to capture the material shortly after discharge and keep the stream coalesced as tightly as possible to reduce induced air. Extended enclosures apply dual skirting to seal the enclosure and use dust curtains to control airflow and allow dust to settle back into the material stream.

Design tools and material flow modeling software helps reduce dust emissions in the transfer point design phase. How the conveyor is operated and maintained also has a significant effect on dust generation and release.

In initial conveyor system designs, emphasis is commonly placed on maximizing production. Experts recommend operators engage in feasibility studies on how the conveyor systems create and emit dust with the goal of improving air quality and workplace safety while still increasing operational efficiency.

Learn more at www.Martin-Eng.com.

Comments