Technofast fasteners for vibrating and crushing applications save installation and maintenance time

A faster and safer way to secure vibrating screen and crusher motor bolts has been shown in service to save two-thirds of the time previously taken for the installation and maintenance of the drives of this ubiquitous industrial comminution equipment.

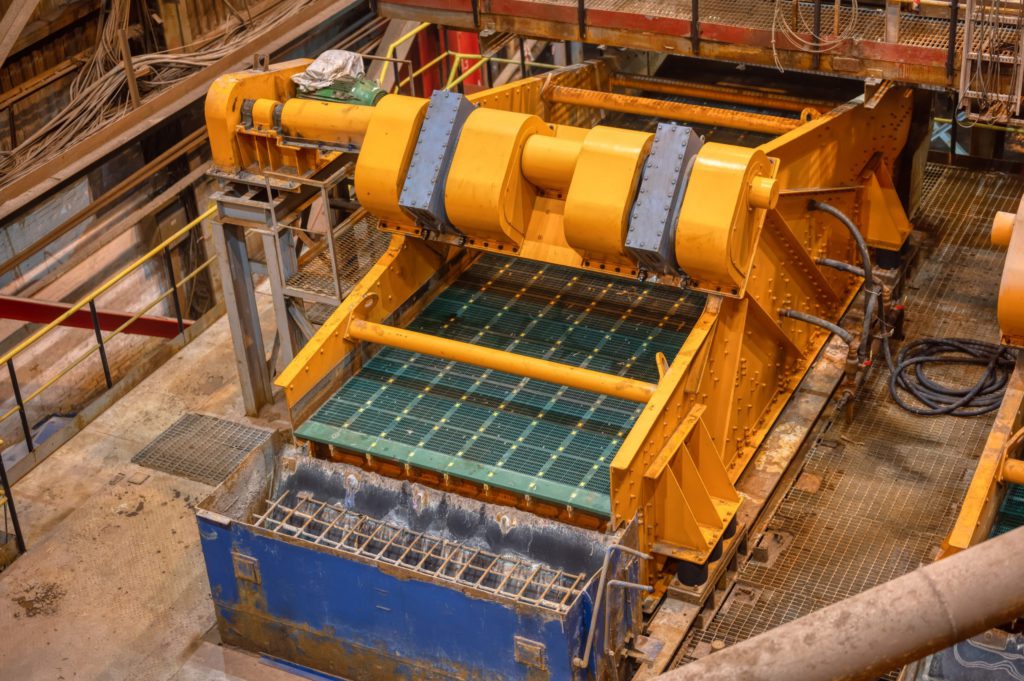

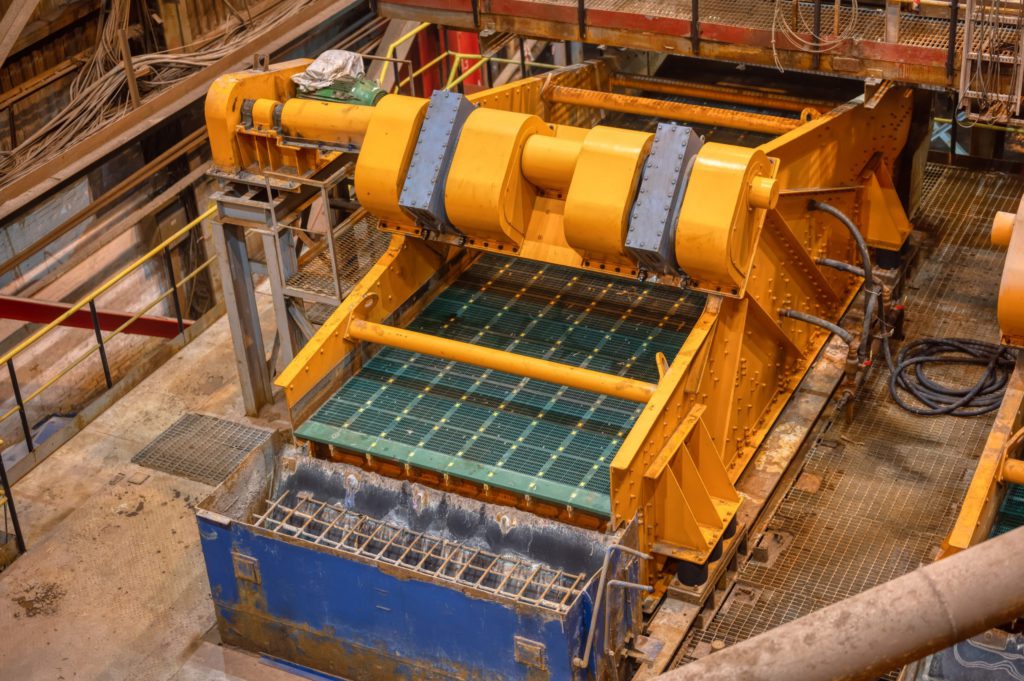

Technofast EziTite Hydraulic Nuts are used to secure vibrating mechanisms and drive motors to sieves, screens and comminution equipment. They are actuated simultaneously to give accurate, even and simultaneous torquing across the sets of bolts used in crusher screen applications such as mineral processing, quarries, roadmix refining and the sorting of industrial materials.

The special fasteners for vibrating and crusher applications incorporate a Poly Washer for extended service, eliminating problems such as hex nuts vibrating loose, lack of control of the bolt load, and physically demanding and hazardous use of flogging wrenches.

“One typical quarry and mining application in Western Australia dramatically cut the installation time of the motor bolts from a six-hour operation needing two or three personnel to a two-hour operation involving two people,” says Technofast founder and CEO John Bucknell. “The machine operator involved reported that using the poly washer as a shock-resistant component and tensioning them simultaneously with precise accuracy is a game changer.”

EziTite Hydraulic Nuts and Bolts are rapidly applied by being placed installed on bolt studs and then hydraulically actuated, stretching the bolt to the precise tension required and then locking it in place mechanically with a locking device. The reverse procedure permits equally rapid disassembly when it is eventually required for maintenance.

Based in Brisbane, Australia, Technofast Industries is a worldwide leader and specialist in bolt tensioning, providing innovative and effective technical solutions along with uncompromising customer service.

For more information see http://www.technofast.com/.

Comments