OTTAWA –

The Mining Association of Canada has awarded two Towards Sustainable Mining (TSM) Excellence awards this year – one to the Ekati diamond mine belonging to

Dominion Diamond Corp. and another to the Voisey’s Bay nickel-cobalt mine of

Vale Newfoundland.

[caption id="attachment_1003718306" align="alignleft" width="300"]

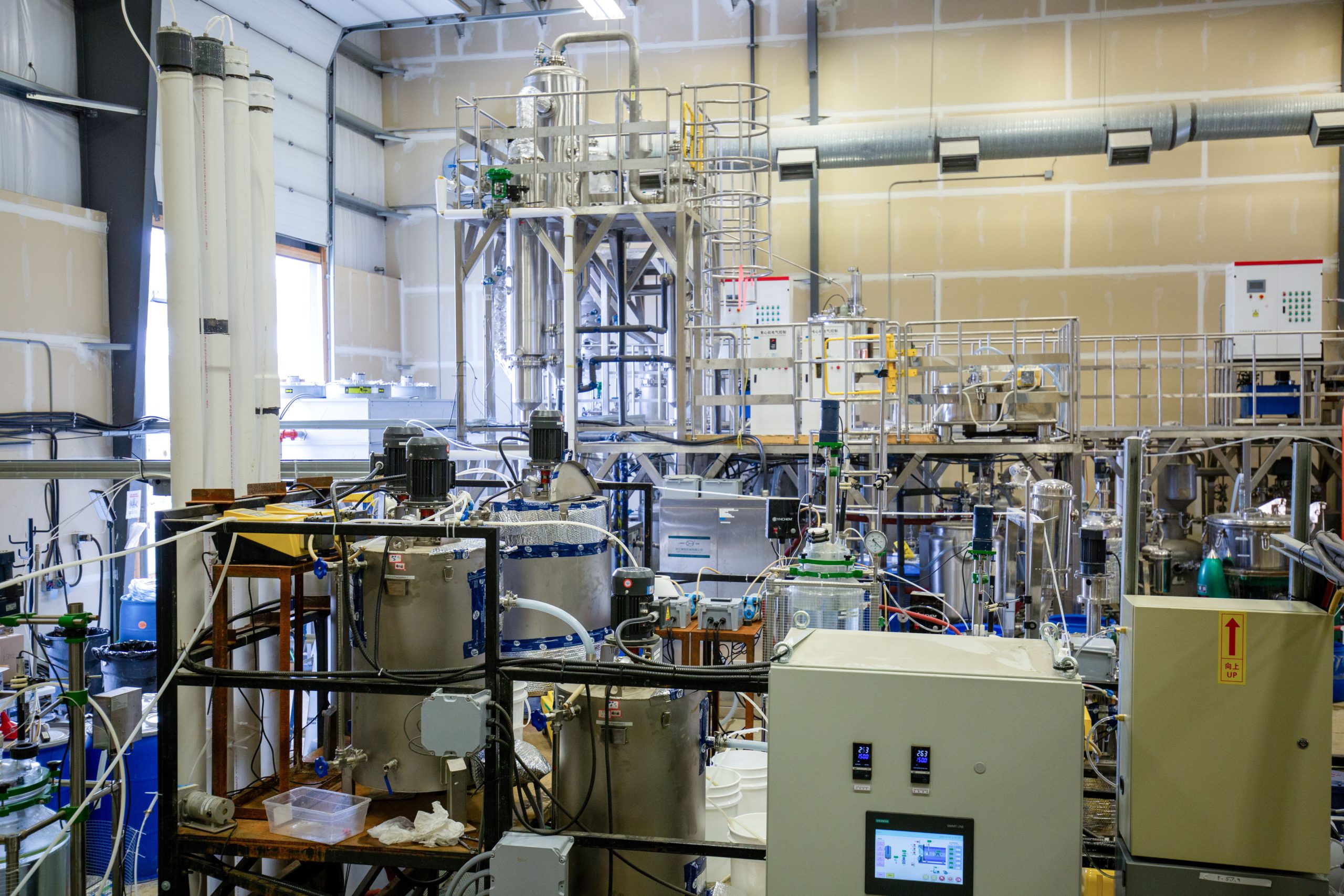

Dominion Diamond has greatly reduced the amount of waste from the Ekati mine.

Dominion Diamond has greatly reduced the amount of waste from the Ekati mine.[/caption]

The Ekati mine won recognition for transforming how waste is handled at the site. In 2013, Dominion began purchasing environmentally friendly products and diverting material from its incinerators, notably nearly 75,000 kg of plastic and 193,000 kg of oily rags to date. Such materials are either recycled or sent for specialty disposal. In 2015, the company installed an in-vessel composter – a first in Canada’s North. Currently half of the organic waste, more than 67,000 kg so far, at the site has been composted rather than incinerated. The composter saved 210 tonnes of carbon dioxide equivalent and 74,000 litres of diesel fuel. Last year Dominion began a study to test the use of composted material for reclamation work.

[caption id="attachment_1003718304" align="alignright" width="300"]

Vale goes to extraordinary lengths to ensure that shipping concentrates from the Voisey’s Bay mine interferes as little as possible with traditional use of the frozen sea.

Vale goes to extraordinary lengths to ensure that shipping concentrates from the Voisey’s Bay mine interferes as little as possible with traditional use of the frozen sea.[/caption]

At the Voisey’s Bay mine, Vale uses Anaktalak Bay for both shipping concentrate and resupplying the site. The company takes extra steps to ensure that its ship movements do not interfere with traditional lifestyles and transportation. In 2007, feedback from the community made Vale to look into how much time it took to safely cross the ice after a ship had passed by. The company developed and deployed a floating pontoon-type bridges along the 40-km shipping route in 2008. Markers, signage and special communications alert everyone about where the bridges are located. In the fall when the ice is forming and in the spring during break-up, no shipping takes place.

Learn more about MAC’s TSM program at

www.Mining.ca.

Dominion Diamond has greatly reduced the amount of waste from the Ekati mine.[/caption]

The Ekati mine won recognition for transforming how waste is handled at the site. In 2013, Dominion began purchasing environmentally friendly products and diverting material from its incinerators, notably nearly 75,000 kg of plastic and 193,000 kg of oily rags to date. Such materials are either recycled or sent for specialty disposal. In 2015, the company installed an in-vessel composter – a first in Canada’s North. Currently half of the organic waste, more than 67,000 kg so far, at the site has been composted rather than incinerated. The composter saved 210 tonnes of carbon dioxide equivalent and 74,000 litres of diesel fuel. Last year Dominion began a study to test the use of composted material for reclamation work.

[caption id="attachment_1003718304" align="alignright" width="300"]

Dominion Diamond has greatly reduced the amount of waste from the Ekati mine.[/caption]

The Ekati mine won recognition for transforming how waste is handled at the site. In 2013, Dominion began purchasing environmentally friendly products and diverting material from its incinerators, notably nearly 75,000 kg of plastic and 193,000 kg of oily rags to date. Such materials are either recycled or sent for specialty disposal. In 2015, the company installed an in-vessel composter – a first in Canada’s North. Currently half of the organic waste, more than 67,000 kg so far, at the site has been composted rather than incinerated. The composter saved 210 tonnes of carbon dioxide equivalent and 74,000 litres of diesel fuel. Last year Dominion began a study to test the use of composted material for reclamation work.

[caption id="attachment_1003718304" align="alignright" width="300"] Vale goes to extraordinary lengths to ensure that shipping concentrates from the Voisey’s Bay mine interferes as little as possible with traditional use of the frozen sea.[/caption]

At the Voisey’s Bay mine, Vale uses Anaktalak Bay for both shipping concentrate and resupplying the site. The company takes extra steps to ensure that its ship movements do not interfere with traditional lifestyles and transportation. In 2007, feedback from the community made Vale to look into how much time it took to safely cross the ice after a ship had passed by. The company developed and deployed a floating pontoon-type bridges along the 40-km shipping route in 2008. Markers, signage and special communications alert everyone about where the bridges are located. In the fall when the ice is forming and in the spring during break-up, no shipping takes place.

Learn more about MAC’s TSM program at

Vale goes to extraordinary lengths to ensure that shipping concentrates from the Voisey’s Bay mine interferes as little as possible with traditional use of the frozen sea.[/caption]

At the Voisey’s Bay mine, Vale uses Anaktalak Bay for both shipping concentrate and resupplying the site. The company takes extra steps to ensure that its ship movements do not interfere with traditional lifestyles and transportation. In 2007, feedback from the community made Vale to look into how much time it took to safely cross the ice after a ship had passed by. The company developed and deployed a floating pontoon-type bridges along the 40-km shipping route in 2008. Markers, signage and special communications alert everyone about where the bridges are located. In the fall when the ice is forming and in the spring during break-up, no shipping takes place.

Learn more about MAC’s TSM program at

Comments