[caption id="attachment_1003745862" align="aligncenter" width="550"]

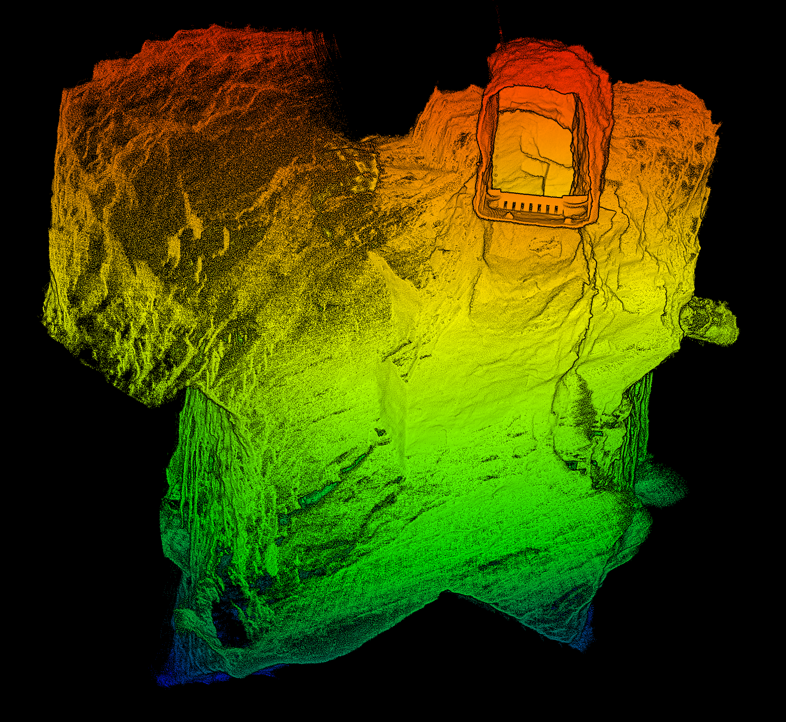

Stope imaging. Credit: Emesent

Stope imaging. Credit: Emesent[/caption]

Australian mid-tier gold mining company

Evolution owns and operates four mines in Australia and one in Ontario, Canada. Located 600 km east of Perth, Mungari underground operation produces more than 125,000 oz. of gold a year.

Improving stope economics

Mungari’s gold mineralization occurs in a zone 70 metres wide by 400 metres long (230 ft. by 1,300 ft.), with ore lodes two to 20 meters (6 ft. to 65 ft.) thick. The site uses a narrow top-down bench stoping with paste fill mining method.

Until February 2020, a traditional cavity monitoring system (CMS) was used to scan stopes. This data gathering method was time consuming and posed a safety risk to personnel performing the surveys. Data coverage and quality were poor, forcing mine engineers and planners to make decisions on stope design based on limited and potentially inaccurate information—increasing the risk to the economics of the stope.

Mungari management sought a stope mapping solution that delivered rich, shadowless data and could be deployed quickly and easily by onsite personnel.

In March 2020, Evolution’s survey team purchased a

Hovermap LiDAR (light detection and ranging) mapping system for the Mungari site. Hovermap was originally intended for mapping stopes only. However, the team soon realized the level of data quality and coverage it could provide made it an ideal choice for other mapping applications. Its use escalated and it is now the preferred tool for mapping all voids at Mungari. The survey team, no longer limited by obstructions or corners, can simply fly Hovermap, mounted to a DJI M210 drone, into a void to capture the data they need.

“Hovermap has been an unprecedented success in our eyes” said Matt Jones, senior surveyor at the site. “This game changing piece of technology allows us to make much more informed decisions about our underground voids, with data collection that is orders of magnitude above existing methods, yet with shorter data collection and processing time. The teams on site have been totally blown away by the level of detail they now have access to, and consider it an essential piece of equipment.”

Point cloud data captured by Hovermap is imported directly into Deswik.AdvSurvey using a semi-automated workflow developed by Deswik to link the two solutions. The data is georeferenced, cleansed, and validated, ready to be delivered as a detailed model, free of shadows and artifacts, to other teams, in less than five minutes.

Using accurate data to optimize stope design and mine planning

Using Hovermap to scan voids at Mungari allows mine personnel to plan and manage stopes more effectively. The insights provided by Hovermap help to eliminate ‘guess work’. Armed with quality data, the technical services team can tackle stope bridging events and dilution due to over-break with a much better understanding.

Even though the survey team had limited drone experience, they quickly mastered Hovermap’s easy-to-use interface and developed the competence to fly in challenging environments. This makes it an efficient and cost effective means of collecting data.

At the end of each month, the team no longer needs to splice shadowed CMS data to calculate stope shapes, as Hovermap provides close to 100% data coverage. Armed with accurate stope data, it only takes them a few minutes to import, georeference and deliver a void model for reconciliation.

Access to this high quality, accurate data is enabling Evolution to optimize the Mungari mine plan.

Evolution also uses Hovermap at its Red Lake Operations.

Hear the full story in this 21-minute webinar with Mungari’s Senior Surveyor:

https://hubs.ly/H0Hb8H60.

Comments