[caption id="attachment_1003731368" align="aligncenter" width="470"]

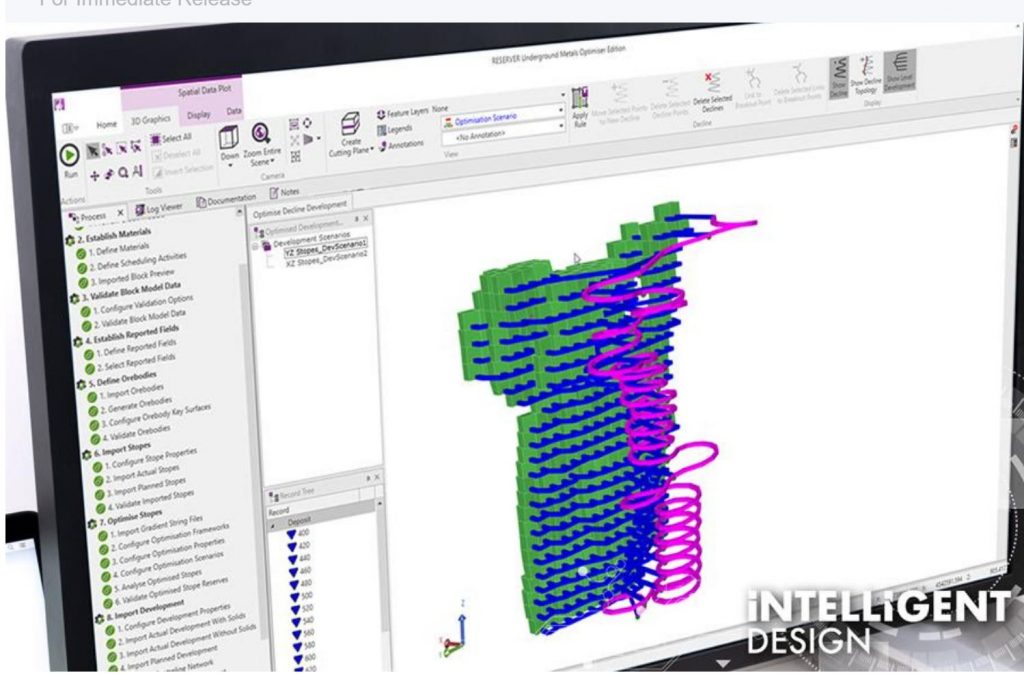

Data generated by RMPGlobal’s new Underground Metals Solution Optimiser.

Data generated by RMPGlobal’s new Underground Metals Solution Optimiser.[/caption]

AUSTRALIA –

RPMGlobal has delivered on its commitment to release an innovative design solution to the market before the end of the year, unveiling its Underground Metals Solution (UGMS) Optimiser edition for mine planning customers.

UGMS Optimiser marks the first edition of RPM’s agile design software offering which is fully integrated with the company’s market leading enterprise solutions.

RPM’s agile design application uses parameters and automatic design tools to build an optimal mine design for users. The time saved by using automatic design tools facilitates the ability for many alternative designs to be generated for consideration. The user similarly changes whatever parameters they want and then re-runs the model to generate the optimal mine design based on the new parameters.

Commenting on the launch of RPM’s first design solution, RPMGlobal CEO Richard Mathews said, “At RPM, we are looking at design differently. We have leveraged the most advanced technologies including the very latest parametric design capabilities that support rapid scenario generation, long term planning and optimal mine design for our customers,” he said. “This ensures miners continue to drive efficiency and productivity improvements in a visually orientated environment.”

“While our design solutions will initially be offered to UGMS customers of RPM’s XPAC solutions software, we are looking forward to rolling out additional design capabilities that extend across our enterprise architecture in the near future.”

UGMS Optimiser incorporates discrete optimization tools used in underground metals mine design all in one solution.

This integration enables users to rapidly understand the impact of changes to key economic drivers such as metallurgical grade, mining costs, revenue, forex, and the roll-on effects these have on accessing the mineral deposits to be mined.

This new design solution uses RPM’s Development Optimiser, an industry first combination of Planar Underground Network Optimiser (PUNO) and Decline Optimisation Tool (DOT) solutions to determine the most economical network of tunnels to access and extract ore on each level of the mine.

Development Optimiser combines both tools in a parametric manner allowing a diligent and extensive analysis of the deposit based on realistic constraints.

The solution also uses Mine Stope Optimiser (MSO) to produce the stope shapes and stope inventories from a block model that spatially represents the location of the mineralization.

Depending on the size and mineral variation in the orebody or orebodies, using a manual process of generating the mining shapes to maximise the recovered resource value can take months. MSO has taken this manual process and reduced it down to days.

Other key features, such as direct integration with the scheduler and enterprise solution, automated development creation and high level financial analysis of the optimised outcome differentiate RPM’s design offering from other in the market which are not enterprise connected.

“We are the first company to combine and incorporate the three big underground optimizers (Stope Optimisation, Underground Network Optimiser and Decline Optimisation) into one enterprise enabled design product which is a game changer for the industry, said Mathews. “However, it is just the beginning as we continue expanding our design solutions to complete our end-to-end enterprise offering which spans scheduling, simulation, finance, maintenance, operations and design.”

RPMGlobal has two offices in Canada. Find out where by

clicking here.

Data generated by RMPGlobal’s new Underground Metals Solution Optimiser.[/caption]

AUSTRALIA – RPMGlobal has delivered on its commitment to release an innovative design solution to the market before the end of the year, unveiling its Underground Metals Solution (UGMS) Optimiser edition for mine planning customers.

UGMS Optimiser marks the first edition of RPM’s agile design software offering which is fully integrated with the company’s market leading enterprise solutions.

RPM’s agile design application uses parameters and automatic design tools to build an optimal mine design for users. The time saved by using automatic design tools facilitates the ability for many alternative designs to be generated for consideration. The user similarly changes whatever parameters they want and then re-runs the model to generate the optimal mine design based on the new parameters.

Commenting on the launch of RPM’s first design solution, RPMGlobal CEO Richard Mathews said, “At RPM, we are looking at design differently. We have leveraged the most advanced technologies including the very latest parametric design capabilities that support rapid scenario generation, long term planning and optimal mine design for our customers,” he said. “This ensures miners continue to drive efficiency and productivity improvements in a visually orientated environment.”

“While our design solutions will initially be offered to UGMS customers of RPM’s XPAC solutions software, we are looking forward to rolling out additional design capabilities that extend across our enterprise architecture in the near future.”

UGMS Optimiser incorporates discrete optimization tools used in underground metals mine design all in one solution.

This integration enables users to rapidly understand the impact of changes to key economic drivers such as metallurgical grade, mining costs, revenue, forex, and the roll-on effects these have on accessing the mineral deposits to be mined.

This new design solution uses RPM’s Development Optimiser, an industry first combination of Planar Underground Network Optimiser (PUNO) and Decline Optimisation Tool (DOT) solutions to determine the most economical network of tunnels to access and extract ore on each level of the mine.

Development Optimiser combines both tools in a parametric manner allowing a diligent and extensive analysis of the deposit based on realistic constraints.

The solution also uses Mine Stope Optimiser (MSO) to produce the stope shapes and stope inventories from a block model that spatially represents the location of the mineralization.

Depending on the size and mineral variation in the orebody or orebodies, using a manual process of generating the mining shapes to maximise the recovered resource value can take months. MSO has taken this manual process and reduced it down to days.

Other key features, such as direct integration with the scheduler and enterprise solution, automated development creation and high level financial analysis of the optimised outcome differentiate RPM’s design offering from other in the market which are not enterprise connected.

“We are the first company to combine and incorporate the three big underground optimizers (Stope Optimisation, Underground Network Optimiser and Decline Optimisation) into one enterprise enabled design product which is a game changer for the industry, said Mathews. “However, it is just the beginning as we continue expanding our design solutions to complete our end-to-end enterprise offering which spans scheduling, simulation, finance, maintenance, operations and design.”

RPMGlobal has two offices in Canada. Find out where by

Data generated by RMPGlobal’s new Underground Metals Solution Optimiser.[/caption]

AUSTRALIA – RPMGlobal has delivered on its commitment to release an innovative design solution to the market before the end of the year, unveiling its Underground Metals Solution (UGMS) Optimiser edition for mine planning customers.

UGMS Optimiser marks the first edition of RPM’s agile design software offering which is fully integrated with the company’s market leading enterprise solutions.

RPM’s agile design application uses parameters and automatic design tools to build an optimal mine design for users. The time saved by using automatic design tools facilitates the ability for many alternative designs to be generated for consideration. The user similarly changes whatever parameters they want and then re-runs the model to generate the optimal mine design based on the new parameters.

Commenting on the launch of RPM’s first design solution, RPMGlobal CEO Richard Mathews said, “At RPM, we are looking at design differently. We have leveraged the most advanced technologies including the very latest parametric design capabilities that support rapid scenario generation, long term planning and optimal mine design for our customers,” he said. “This ensures miners continue to drive efficiency and productivity improvements in a visually orientated environment.”

“While our design solutions will initially be offered to UGMS customers of RPM’s XPAC solutions software, we are looking forward to rolling out additional design capabilities that extend across our enterprise architecture in the near future.”

UGMS Optimiser incorporates discrete optimization tools used in underground metals mine design all in one solution.

This integration enables users to rapidly understand the impact of changes to key economic drivers such as metallurgical grade, mining costs, revenue, forex, and the roll-on effects these have on accessing the mineral deposits to be mined.

This new design solution uses RPM’s Development Optimiser, an industry first combination of Planar Underground Network Optimiser (PUNO) and Decline Optimisation Tool (DOT) solutions to determine the most economical network of tunnels to access and extract ore on each level of the mine.

Development Optimiser combines both tools in a parametric manner allowing a diligent and extensive analysis of the deposit based on realistic constraints.

The solution also uses Mine Stope Optimiser (MSO) to produce the stope shapes and stope inventories from a block model that spatially represents the location of the mineralization.

Depending on the size and mineral variation in the orebody or orebodies, using a manual process of generating the mining shapes to maximise the recovered resource value can take months. MSO has taken this manual process and reduced it down to days.

Other key features, such as direct integration with the scheduler and enterprise solution, automated development creation and high level financial analysis of the optimised outcome differentiate RPM’s design offering from other in the market which are not enterprise connected.

“We are the first company to combine and incorporate the three big underground optimizers (Stope Optimisation, Underground Network Optimiser and Decline Optimisation) into one enterprise enabled design product which is a game changer for the industry, said Mathews. “However, it is just the beginning as we continue expanding our design solutions to complete our end-to-end enterprise offering which spans scheduling, simulation, finance, maintenance, operations and design.”

RPMGlobal has two offices in Canada. Find out where by

Comments