RICHMOND, British Columbia – With each new release of

Readyline in 2016, mines get closer and closer to stopping all equipment problems before they start.

Wenco’s asset health management system changed the way mines monitored machine condition when it debuted in 2015. The original Readyline took data from OEM systems and gave it to the maintenance crew. Sensor reports and alarms kept mines on top of asset health like never before.

Since then, the excitement around Readyline has spurred non-stop development. Every few months, releases have added advanced features to make the system smarter and sleeker.

In version 1.2, GPS position stamping showed just where and when health events occurred. Version 1.3 brought enhanced dashboards to provide a deeper level of reporting with greater display capabilities.

Now, the version of Readyline coming this July introduces two innovations that give mines unprecedented flexibility over their condition monitoring.

[caption id="attachment_1003713814" align="alignleft" width="300"]

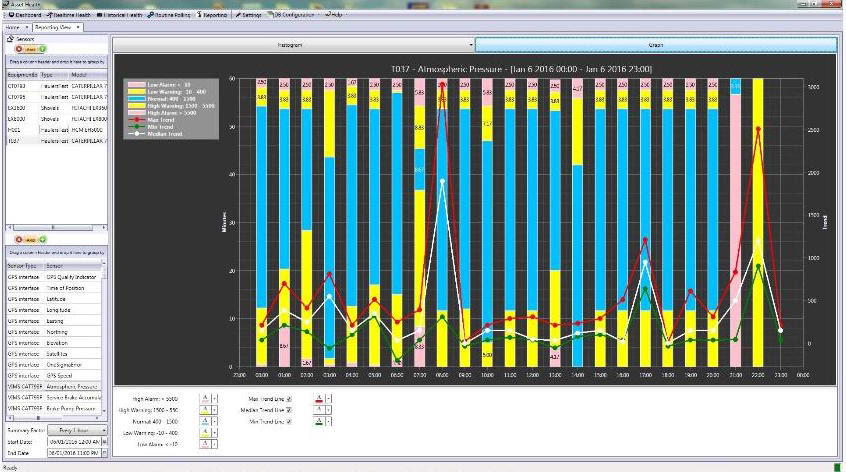

Screen capture from Readyline 1.4, coming in July 2016.

Screen capture from Readyline 1.4, coming in July 2016.[/caption]

Readyline version 1.4 incorporates virtual signals and alarms to complement the OEM data already working in the system. With a few clicks, mines can select multiple sensors and define their thresholds to track a set of conditions, even if the OEM system lacks a native signal for them.

For example, a mine can track the cooling efficiency of its engines by entering the following formula in the virtual signal window:

Cooling Efficiency f(x) = (Engine RPM >58.2 * (TemperatureEngine – TemperatureCoolant) / (TemperatureEngine – TemperatureAmbient)

Then, maintenance can set Readyline to poll and watch the cooling data stream into the dashboard.

Along with virtual signals, this latest release also introduces Readyline to a brand new database structure. Our new time series database with scalable server architecture moves the system away from the siloed SQL database and toward a true Big Data solution. With the additional storage and access power, maintenance crew can instantly sift through years of historical sensor data to pinpoint any facts and trends they need.

“This is a solution that can really change how a mine performs,” said Hiro Hirowatari, Wenco director of technology. “Readyline has advanced a lot in a short time and the outcomes are substantial.

“Now, with virtual signals and a better database, mines can monitor machine components any way they want. It ought to have a major effect on equipment uptime and preventive maintenance — even more than before.”

To find out more about Readyline, contact us at

sales@wencomine.com or

604.270.8277.

Screen capture from Readyline 1.4, coming in July 2016.[/caption]

Readyline version 1.4 incorporates virtual signals and alarms to complement the OEM data already working in the system. With a few clicks, mines can select multiple sensors and define their thresholds to track a set of conditions, even if the OEM system lacks a native signal for them.

For example, a mine can track the cooling efficiency of its engines by entering the following formula in the virtual signal window:

Cooling Efficiency f(x) = (Engine RPM >58.2 * (TemperatureEngine – TemperatureCoolant) / (TemperatureEngine – TemperatureAmbient)

Then, maintenance can set Readyline to poll and watch the cooling data stream into the dashboard.

Along with virtual signals, this latest release also introduces Readyline to a brand new database structure. Our new time series database with scalable server architecture moves the system away from the siloed SQL database and toward a true Big Data solution. With the additional storage and access power, maintenance crew can instantly sift through years of historical sensor data to pinpoint any facts and trends they need.

“This is a solution that can really change how a mine performs,” said Hiro Hirowatari, Wenco director of technology. “Readyline has advanced a lot in a short time and the outcomes are substantial.

“Now, with virtual signals and a better database, mines can monitor machine components any way they want. It ought to have a major effect on equipment uptime and preventive maintenance — even more than before.”

To find out more about Readyline, contact us at

Screen capture from Readyline 1.4, coming in July 2016.[/caption]

Readyline version 1.4 incorporates virtual signals and alarms to complement the OEM data already working in the system. With a few clicks, mines can select multiple sensors and define their thresholds to track a set of conditions, even if the OEM system lacks a native signal for them.

For example, a mine can track the cooling efficiency of its engines by entering the following formula in the virtual signal window:

Cooling Efficiency f(x) = (Engine RPM >58.2 * (TemperatureEngine – TemperatureCoolant) / (TemperatureEngine – TemperatureAmbient)

Then, maintenance can set Readyline to poll and watch the cooling data stream into the dashboard.

Along with virtual signals, this latest release also introduces Readyline to a brand new database structure. Our new time series database with scalable server architecture moves the system away from the siloed SQL database and toward a true Big Data solution. With the additional storage and access power, maintenance crew can instantly sift through years of historical sensor data to pinpoint any facts and trends they need.

“This is a solution that can really change how a mine performs,” said Hiro Hirowatari, Wenco director of technology. “Readyline has advanced a lot in a short time and the outcomes are substantial.

“Now, with virtual signals and a better database, mines can monitor machine components any way they want. It ought to have a major effect on equipment uptime and preventive maintenance — even more than before.”

To find out more about Readyline, contact us at

Comments