[caption id="attachment_1003721884" align="aligncenter" width="457"]

BinMaster software pinpoints uneven loading, avoids damage to bins or silos.

BinMaster software pinpoints uneven loading, avoids damage to bins or silos.[/caption]

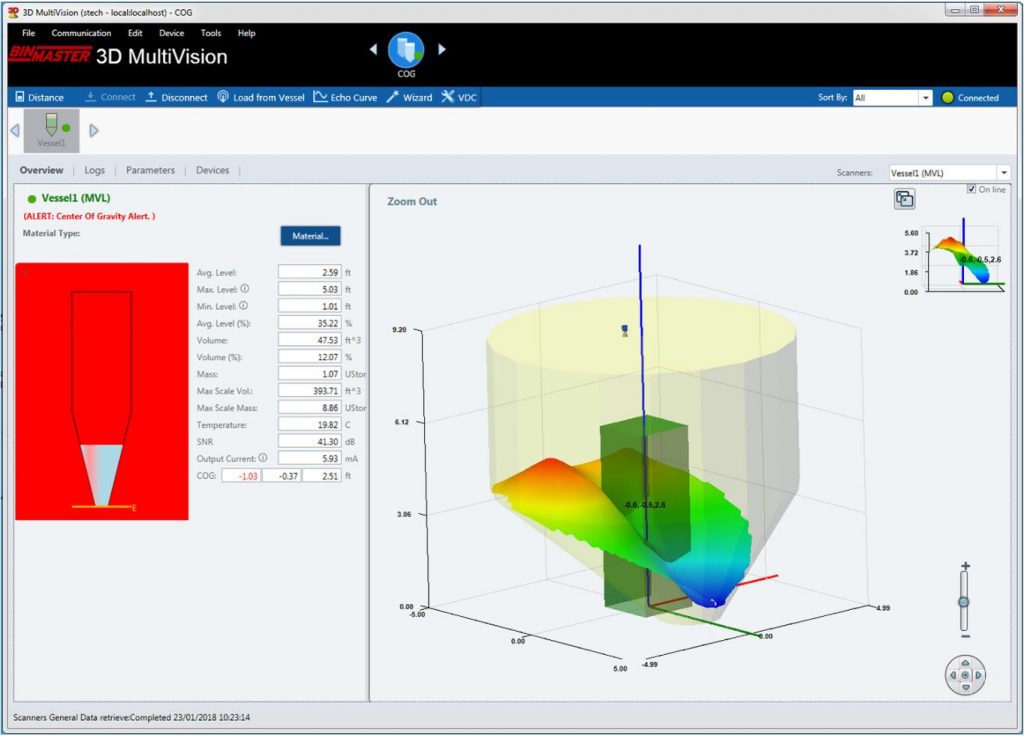

LINCOLN, Neb. – The walls of steel and concrete silos have been known to wear or fail causing cracking, denting, buckling, and bending that can lead to catastrophic collapse. For operations that want to detect uneven loading of silos that contribute to these failures,

BinMaster offers a new software option that uses 3DLevelScanners to identify the location of the center of gravity, display it graphically, and alert when the center of gravity falls outside of a predefined area.

A 3DLevelScanner is mounted on the roof of the silo in an optimal location to view the material surface in the silo. Level measurements are used to determine the X, Y, and Z co-ordinates of the center of gravity based upon the material topography. The co-ordinates are processed in the 3DMultiVision software via a proprietary RS-485 communication protocol. Users define the alert parameters and accepted area into which the center of gravity must fall. A 3D visual will indicate where the center of gravity is located and show the acceptable area.

Operators can use this unique solution to help reduce structural stress when loading or emptying a silo. It is a valuable preventive maintenance tool that can alert to the need for inspection or cleaning. Use over time can prolong silo integrity and create a safer environment by alerting to potential structural stress caused by uneven loading.

Please visit

www.BinMaster.com to locate the nearest dealer.

BinMaster software pinpoints uneven loading, avoids damage to bins or silos.[/caption]

LINCOLN, Neb. – The walls of steel and concrete silos have been known to wear or fail causing cracking, denting, buckling, and bending that can lead to catastrophic collapse. For operations that want to detect uneven loading of silos that contribute to these failures, BinMaster offers a new software option that uses 3DLevelScanners to identify the location of the center of gravity, display it graphically, and alert when the center of gravity falls outside of a predefined area.

A 3DLevelScanner is mounted on the roof of the silo in an optimal location to view the material surface in the silo. Level measurements are used to determine the X, Y, and Z co-ordinates of the center of gravity based upon the material topography. The co-ordinates are processed in the 3DMultiVision software via a proprietary RS-485 communication protocol. Users define the alert parameters and accepted area into which the center of gravity must fall. A 3D visual will indicate where the center of gravity is located and show the acceptable area.

Operators can use this unique solution to help reduce structural stress when loading or emptying a silo. It is a valuable preventive maintenance tool that can alert to the need for inspection or cleaning. Use over time can prolong silo integrity and create a safer environment by alerting to potential structural stress caused by uneven loading.

Please visit

BinMaster software pinpoints uneven loading, avoids damage to bins or silos.[/caption]

LINCOLN, Neb. – The walls of steel and concrete silos have been known to wear or fail causing cracking, denting, buckling, and bending that can lead to catastrophic collapse. For operations that want to detect uneven loading of silos that contribute to these failures, BinMaster offers a new software option that uses 3DLevelScanners to identify the location of the center of gravity, display it graphically, and alert when the center of gravity falls outside of a predefined area.

A 3DLevelScanner is mounted on the roof of the silo in an optimal location to view the material surface in the silo. Level measurements are used to determine the X, Y, and Z co-ordinates of the center of gravity based upon the material topography. The co-ordinates are processed in the 3DMultiVision software via a proprietary RS-485 communication protocol. Users define the alert parameters and accepted area into which the center of gravity must fall. A 3D visual will indicate where the center of gravity is located and show the acceptable area.

Operators can use this unique solution to help reduce structural stress when loading or emptying a silo. It is a valuable preventive maintenance tool that can alert to the need for inspection or cleaning. Use over time can prolong silo integrity and create a safer environment by alerting to potential structural stress caused by uneven loading.

Please visit

Comments