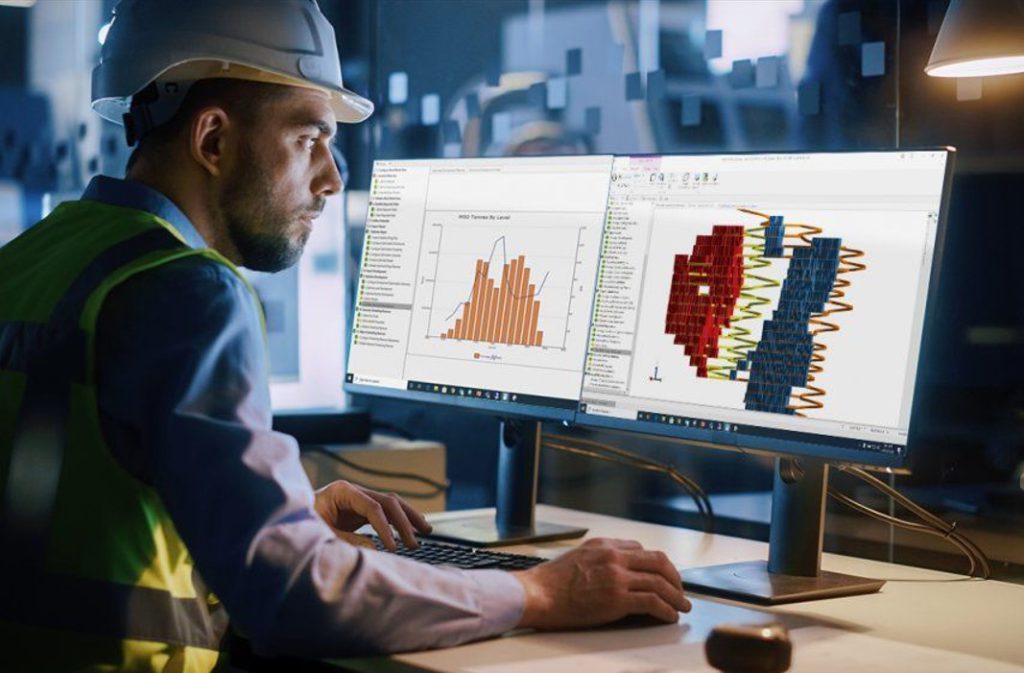

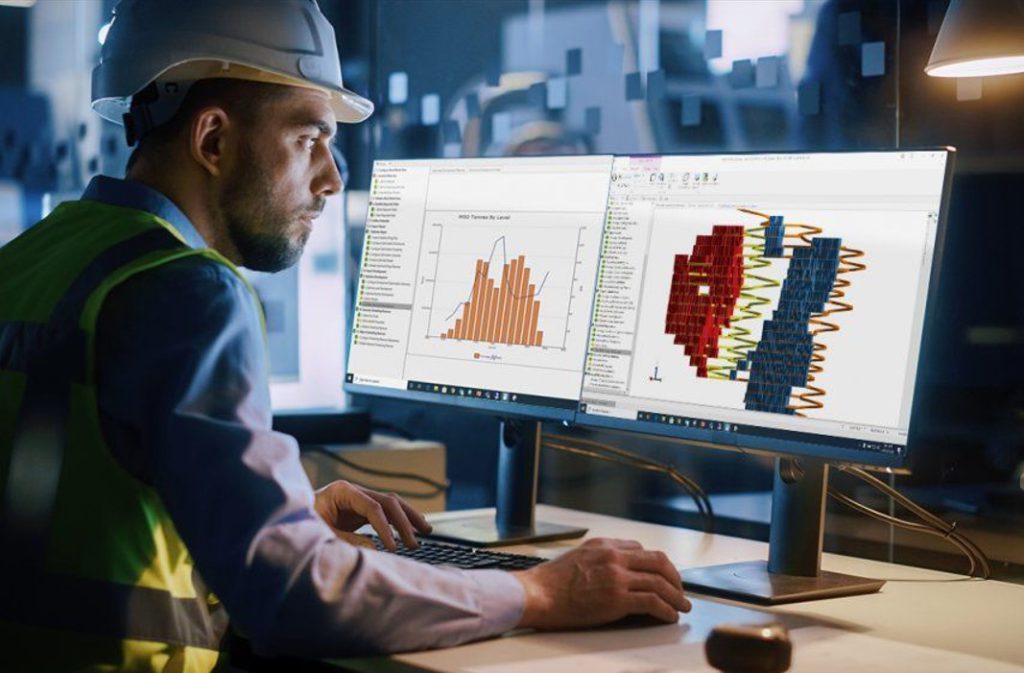

RPM Global acquires MIRARCO software to strengthen design and scheduling

RPM Global (RPM) has made another software acquisition by entering a research partnership with Canadian based MIRARCO. The agreement gives RPM ownership of three mine planning optimization software products that will strengthen RPM’s design and scheduling product suites and particularly strengthen the Schedule Optimization Tool product.

The acquisition is part of a three-year collaborative research partnership with MIRARCO, a research arm of Laurentian University. The organization was instrumental in the original research leading to the development of RPM’s Schedule Optimisation Tool. SOT, along with Attain and Surface SOT, were products acquired by RPM as part of its July 2020 acquisition of Revolution Mining Software.

MIRARCO has developed three separate but complementary underground mine planning optimization products, which RPM has under this agreement agreed to acquire and commercialize. These products extend and complement the functionality of RPM’s mine optimization software solutions in the areas of advanced valuation, geosequencing and ventilation.

As part of the collaboration arrangement, RPM and MIRARCO will continue to work together on research and development projects that deliver demonstrable and innovative solutions for the mining industry.

The Advanced Valuation Module (AVM) facilitates the generation of optimized underground mine plans that are robust to uncertain product prices and ore grades. The mine planner specifies distributions for product prices over the mine’s life and ore grades. AVM will then optimize the life-of-mine schedule, maximizing the operation’s net present value (NPV).

The GeoSequencing Module (GSM) facilitates the generation of optimized underground mine schedules adhering to stope sequencing constraints that are motivated by geotechnical considerations. The mine planner selects the rules for stope sequencing and GSM automatically generates alternative sets of stope-to-stope dependencies, or GeoSequencing scenarios, while enforcing the selected rules. The output is an NPV optimized life-of-mine schedule based on the mine’s geotechnical considerations.

The Ventilation Constraint Module (VCM) generates optimized underground mine schedules based on ventilation constraints. Through interaction with a ventilation solver, VCM automatically generates airflow-based constraints on the equipment for each ventilation district. Using these constraints, VCM generates optimized NPV life-of-mine schedules that are feasible from a ventilation perspective.

The acquisition was completed on Dec. 17.

Visit www.RPMGlobal.com for additional information.

Comments