Rock Tech promotes use of lithium by-products in cement production

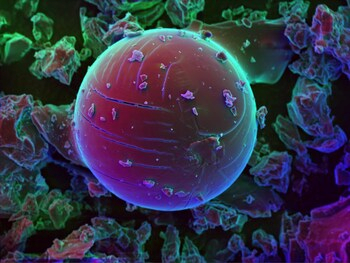

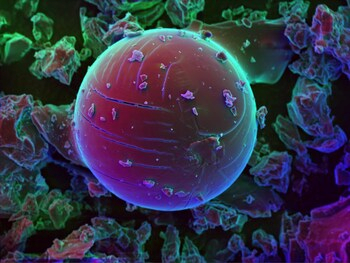

Rock Tech Lithium (TSXV: RCK; OTCQX: RCKTF) foresees using the by-products of lithium production from its plant in Guben, Germany, to replace fly ash in cement production. The product properties of Portland cement area improved, and carbon dioxide emissions are reduced in the construction industry.

Rock Tech points to a peer-reviewed study published by the German Lithium Institute that confirmed that leached spodumene concentrate (LSC) generated during the production of lithium can be used as an additive in cement to reduce fly ash use. Fly ash is expected to become scarce as coal-fired power plants are phased out to reduce CO2 emissions.

The by-product material is primarily composed of aluminosilicates, meaning that it can ensure the regional supply security of the German cement industry with LSC and help reduce CO2 emissions.

Jannik Schmitz, supply chain manager at ITEL shareholder Rock Tech says "ITEL's study takes us a big step further on our path to CO2 neutrality and becoming the first zero-waste lithium company worldwide. It is important to note that the suitability of LSC as a cement additive is independent of the origin of the spodumene used. This confirms our choice of production process and our procurement strategy to source spodumene from several sustainably producing sources."

The compressive strength of Portland cement increases by 10% when 20% LSC is added – regardless of the origin of the spodumene used. The process has been submitted for a patent.

The company has applied for a patent for producing and utilizing the LSC in cement.

Rock Tech plans to build Europe's first lithium converter in Germany. The plant will have an annual production capacity of 24,000 tonnes of lithium hydroxide, enough to provide material for the construction of 500,000 electric batteries. Soon, capacities for material recycling will be developed. Rock Tech aims to become the first zero-waste lithium company in the world through the complete reuse of byproducts.

The study "Properties of low sulfur leached spodumene as supplementary cementitious material in ordinary Portland cement" can be read by clicking here.

Or visit the company’s website at www.RockTechLithium.com.

Comments