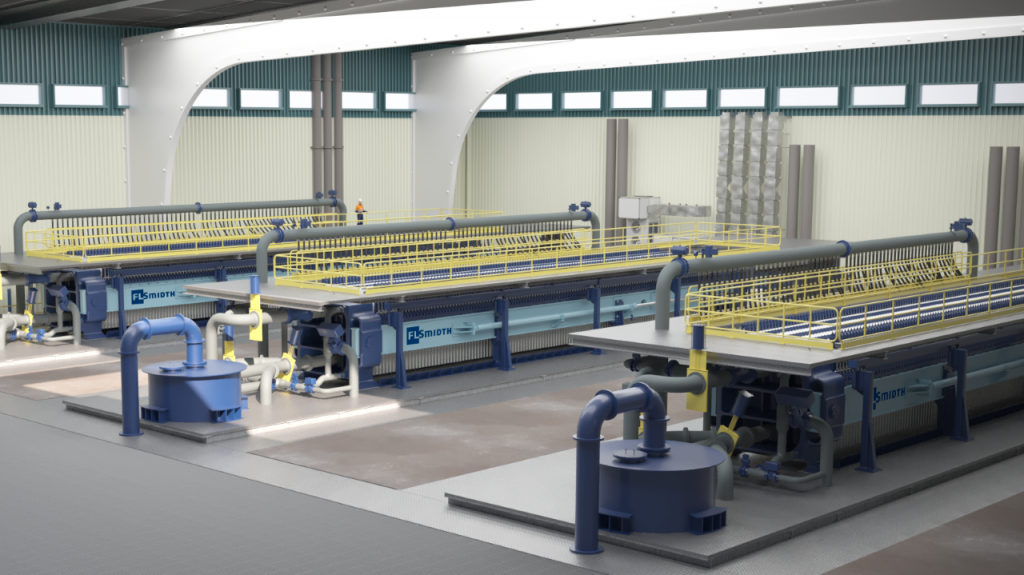

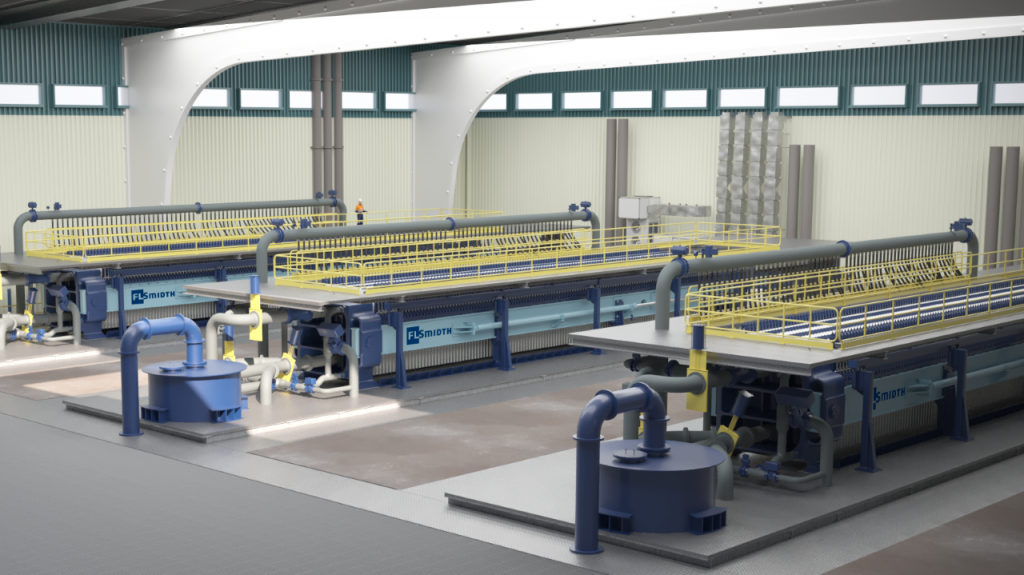

New filter press from FLSmidth delivers high availability and water recovery

FLSmidth has released the AFP2525 automatic filter press, which delivers high availability and efficiency at the lowest cost possible – according to the release, at the lowest cost per tonne of production in the industry. To keep mines operating at their highest levels, all components of the AFP2525 automatic filter press are designed for quick and easy maintenance.

When treating tailings at high volumes, small process disruptions add up. Thus, the company focused on ease and speed of maintenance – the AFP2525 provides fast plate-pack removal, while cloth change and plate maintenance happen outside of the filter, ensuring maximum efficiency and safety while the filter is operating.

“We are delighted to launch this large-scale, cost-competitive filter press to the mining industry. With a combination of fast and safe maintenance, lower costs and a minimized environmental footprint, the AFP2525 immediately becomes the leading solution in its area,” Mikko Keto, mining president with FLSmidth, said in a release. “It meets growing customer demand for fast and efficient water recovery and illustrates our determination to meet our MissionZero ambition and help mining move towards zero water waste by 2030.”

In addition to the low operating costs, the AFP2525 also delivers the lowest cake moistures and the highest production rates – 300 tonnes per hour from a single filter, or 7,200 tonnes a day. The AFP2525 is also highly durable and long-lasting due to a maintenance-friendly, robust design so it is built to last for the life of the mine and beyond.

Ultra-efficient water reclamation allows miners to recycle and reuse a significant amount of water in their operations, reducing the need for fresh water intake. This cuts both water-sourcing and wet tailings management costs for the mine, while reducing its environmental footprint.

The release also notes that the AFP2525 has the highest availability in the industry due to its ease of maintenance and is also ‘exceptionally’ efficient and operates at high capacity, maximizing water recovery, which makes it suitable for large-scale mines.

Fast filtration rates and short mechanical times minimize the filter cycle time. With the AFP2525 automatic filter press, miners can expect an average of 93% availability and up to 95% recovery of process water.

The AFP2525 automatic filter press is a key solution in FLSmidth’s MissionZero ambition to enable mines to eliminate water waste and emissions by 2030.

For more information, visit www.FLSmidth.com.

Comments