NEO Battery manufactures pouch-type fuel cells for NBMSiDE performance testing

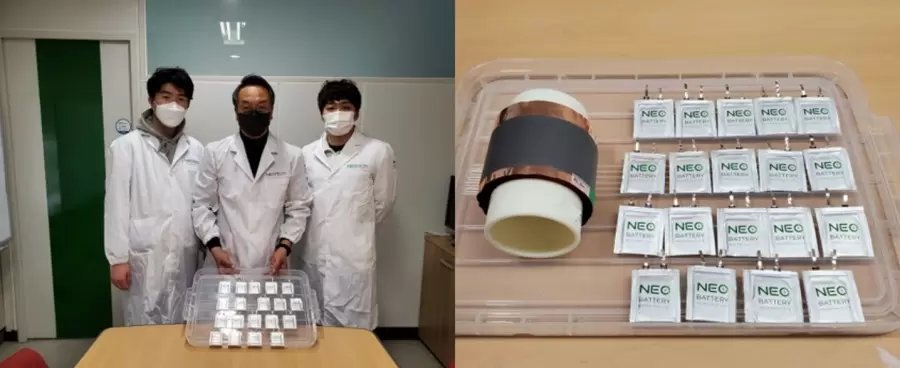

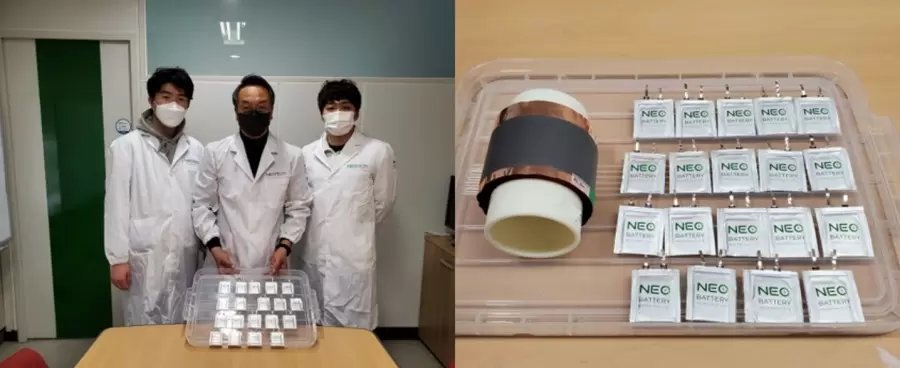

NEO Battery Materials (TSXV: NBM; OTC: NBMFF) has completed the manufacturing of NBMSiDE pouch-type full cells to evaluate the product's performance, viability and durability in genuine battery charging conditions.

NBMSiDE is NEO's flagship silicon anode material for electric vehicle lithium-ion batteries. NBMSiDE comes in three variations, P100, P200, and C100, and is manufactured through the company's proprietary nanocoating technology. All NEO product lines are based on metallurgical-grade silicon microparticles and retain a high specific capacity of >2,500 mAh/g. NBMSiDE is currently pending trademark approval.

In addition, NEO has convened the kick-off meeting for its NBM silicon anode plant project in South Korea with the engineering design company to streamline terms and efforts for fast-tracking construction completion.

NEO commissioned a third-party evaluation agency for a product performance and viability assessment of NBMSiDE through manufacturing and cycle-testing 500 mAh pouch-type full cells. To simulate an authentic battery charging/discharging environment, the pouch full cells utilize nickel-manganese-cobalt (NMC) cathode materials and a composite mixture anode material with 5% to 10% silicon loading of NBMSiDE and graphite.

Following the third party's charging protocols, the tested cells are subjected to a cycle test using a 1C rate (1-hour) charging protocol with dynamic stress tests (DST) and a 100% depth of discharge (DoD), and pouch full cells characterized as high-rate capable cells will be tested with a variety of ultra-fast charging C-rates such as 3C rate (20 minutes) or 5C rate (12 minutes).

In addition, pouch cell electrochemical characteristic evaluations will be conducted in a variety of environments and conditions to confirm the robustness and durability of NBMSiDE, and the third party will provide frequent feedback on progress results.

Through unbiased testing and assessments, NEO is making continuous efforts to ensure objective evaluation and to reserve the functional reliability of NBMSiDE silicon material development.

With the approval of the 9,91-sq.-metre site by the Gyeonggi Province, NEO, through its South Korean subsidiary, started the NBM silicon anode plant project at Oseong International Investment Zone in Pyeongtaek City in March 2022. The contracted engineering process and design company for the NSAP project will be employing a team of eight engineers, currently working on the basic design for the project.

In a concurrent timeline, the design progress of the NSAP project and the procurement-construction preparations for long lead time items will be fulfilled. NEO will commence construction in June 2022, and will follow stringent timelines and protocols to aim completion in June 2023.

For more information, please visit www.neobatterymaterials.com.

Comments