PERU –

GE Power was chosen by

Southern Copper Corp. (SCC) to provide the harmonic filter for its Toquepala concentrator located in southern Tacna. The filter will be integrated into the copper concentrator’s power system to improve the power quality.

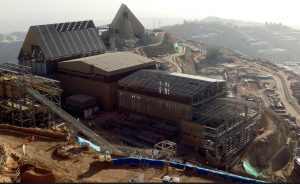

[caption id="attachment_1003721169" align="alignleft" width="300"]

Southern Copper’s Toquepala mill which is being doubled in size.

Southern Copper’s Toquepala mill which is being doubled in size.[/caption]

Grinding mills and its associated power electronic equipment can generate a lot of harmonics that hurt the power network’s stability inside a mine. Consequently, the mine is likely to suffer from power outages. Moreover, the machinery tends to consume more electricity due to the poor power quality and energy efficiency, leading to an excessive energy bill.

Harmonic filter is an effective way to achieve cost reductions through improved power quality and reduced energy losses, which, in turn, improves transmission capacity and helps the power network become more resilient. Improved power quality will also reduce machinery stress and help increase its life expectancy.

“The $1.2 billion Toquepala expansion will see the production capacity of the mine’s copper concentrator double from 60,000 to 120,000 tonnes per day. The harmonic filter is an essential piece of equipment to help us achieve this ambition,” said Eduardo Forcada, project director, SCC. “GE’s e-house harmonic filter solution is quite unique in the Peruvian mining industry. We count on this technology to guarantee the continuity of the production operations with improved cost performance.”

Moreover, GE’s harmonic filter will be enclosed in an e-house. The smaller footprint provides more flexibility when integrating the civil work and can achieve faster installations at the field. As a fully encased stand-alone piece compared to the traditional open rack solution, it also protects the machinery from dust and pollution, thus lowering maintenance cost.

GE has long-standing relationship with SCC. GE has locomotives that transport minerals as well as large motors, switchgears and motor control centres for grinding mills.

See what GE offers to the mining industry. Go to

www.GEPowerConversion.com/industries/mining.

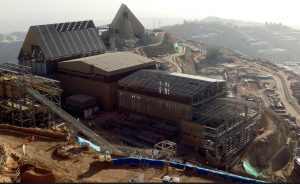

Southern Copper’s Toquepala mill which is being doubled in size.[/caption]

Grinding mills and its associated power electronic equipment can generate a lot of harmonics that hurt the power network’s stability inside a mine. Consequently, the mine is likely to suffer from power outages. Moreover, the machinery tends to consume more electricity due to the poor power quality and energy efficiency, leading to an excessive energy bill.

Harmonic filter is an effective way to achieve cost reductions through improved power quality and reduced energy losses, which, in turn, improves transmission capacity and helps the power network become more resilient. Improved power quality will also reduce machinery stress and help increase its life expectancy.

“The $1.2 billion Toquepala expansion will see the production capacity of the mine’s copper concentrator double from 60,000 to 120,000 tonnes per day. The harmonic filter is an essential piece of equipment to help us achieve this ambition,” said Eduardo Forcada, project director, SCC. “GE’s e-house harmonic filter solution is quite unique in the Peruvian mining industry. We count on this technology to guarantee the continuity of the production operations with improved cost performance.”

Moreover, GE’s harmonic filter will be enclosed in an e-house. The smaller footprint provides more flexibility when integrating the civil work and can achieve faster installations at the field. As a fully encased stand-alone piece compared to the traditional open rack solution, it also protects the machinery from dust and pollution, thus lowering maintenance cost.

GE has long-standing relationship with SCC. GE has locomotives that transport minerals as well as large motors, switchgears and motor control centres for grinding mills.

See what GE offers to the mining industry. Go to

Southern Copper’s Toquepala mill which is being doubled in size.[/caption]

Grinding mills and its associated power electronic equipment can generate a lot of harmonics that hurt the power network’s stability inside a mine. Consequently, the mine is likely to suffer from power outages. Moreover, the machinery tends to consume more electricity due to the poor power quality and energy efficiency, leading to an excessive energy bill.

Harmonic filter is an effective way to achieve cost reductions through improved power quality and reduced energy losses, which, in turn, improves transmission capacity and helps the power network become more resilient. Improved power quality will also reduce machinery stress and help increase its life expectancy.

“The $1.2 billion Toquepala expansion will see the production capacity of the mine’s copper concentrator double from 60,000 to 120,000 tonnes per day. The harmonic filter is an essential piece of equipment to help us achieve this ambition,” said Eduardo Forcada, project director, SCC. “GE’s e-house harmonic filter solution is quite unique in the Peruvian mining industry. We count on this technology to guarantee the continuity of the production operations with improved cost performance.”

Moreover, GE’s harmonic filter will be enclosed in an e-house. The smaller footprint provides more flexibility when integrating the civil work and can achieve faster installations at the field. As a fully encased stand-alone piece compared to the traditional open rack solution, it also protects the machinery from dust and pollution, thus lowering maintenance cost.

GE has long-standing relationship with SCC. GE has locomotives that transport minerals as well as large motors, switchgears and motor control centres for grinding mills.

See what GE offers to the mining industry. Go to

Comments