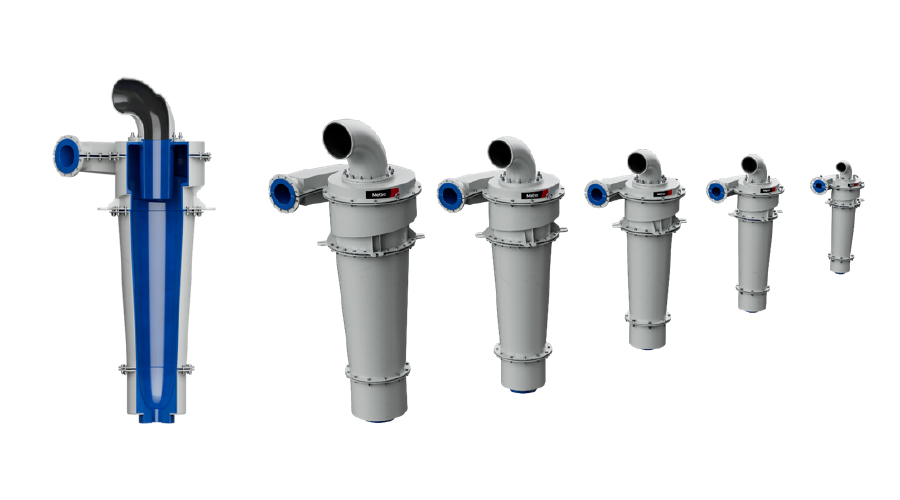

Metso’s new hydrocyclone boosts capacity and cuts waste

Metso has launched its latest hydrocyclone, the MHC CB (curved bottom), designed to make mineral processing more efficient. The new model is part of Metso's MHC family and focuses on increasing capacity while reducing fines and waste, giving a boost to grinding circuits.

This new version builds on Metso’s existing technology but with a patented design that handles more material and separates coarser particles. It works well with newer flotation circuits and helps prevent unwanted fines and water from getting into the underflow.

The MHC CB can be used with different minerals. It’s also easy to add to existing systems. Metso product manager for hydrocyclones Ben Klein says the new design offers more flexibility in dealing with different ore types and grind sizes.

The product was developed in partnership with Anglo American, which helped with large-scale lab and pilot tests. Imperial College also confirmed the new hydrocyclone's performance.

Metso says the MHC CB can handle a range of minerals like lithium, gold, nickel, and copper, as well as materials like limestone and silica.

Plus, it's part of Metso’s planet positive offering, using less energy and producing fewer carbon emissions than older wet classification methods.

For more details, visit www.Metso.com.

Comments