Metso Outotec launches LowNOx burner for travelling grate pelletizing plants

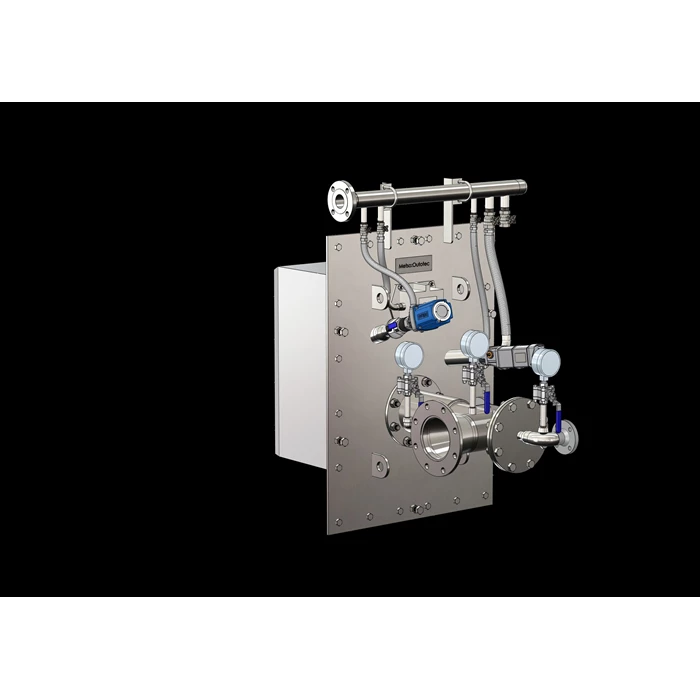

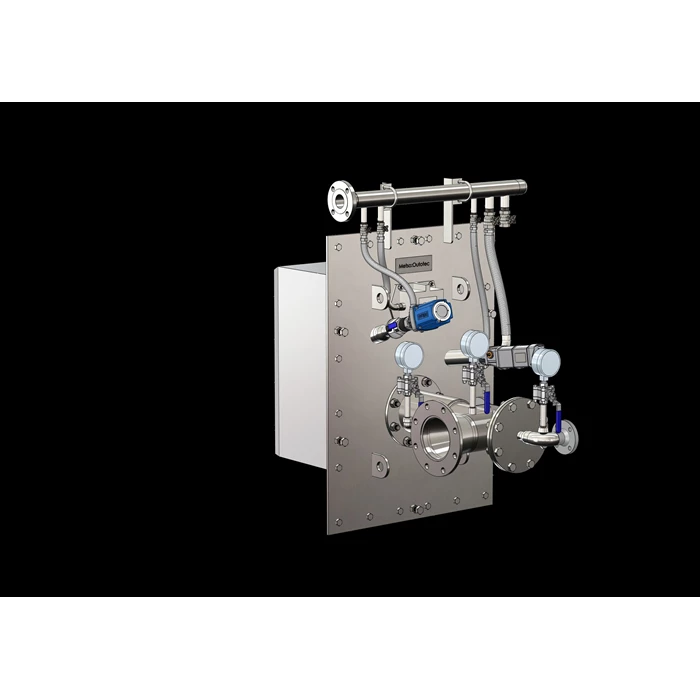

Metso Outotec is launching the innovative Ferroflame LowNOx (nitrogen oxides) burner for travelling grate pelletizing plants to enable pellet plant operators to achieve the stringent NOx emission targets with ease. The new burner is part of the company’s Planet Positive offering focused on environmentally efficient technologies.

The Ferroflame LowNOx burner uses high-speed dilution, which is an effective way to improve the combustion process and reduce NOx emissions. It works seamlessly with natural gas, and tests demonstrate that can also be used with diesel and coke oven gas.

“We are very excited about the Ferroflame LowNOx burner, our emission- and cost-efficient alternative to minimize NOx emissions from the combustion process. Its functionality and performance with natural gas have been proven on-site. The burners have been operating successfully at a client site since 2019,” said Andreas Munko, senior product manager, ferrous and heat transfer, at Metso Outotec.

Metso Outotec’s Ferroflame LowNOx burner provides the following benefits:

More information about Ferroflame burners is available at www.mogroup.com/portfolio/ferroflame-lownox.

Comments