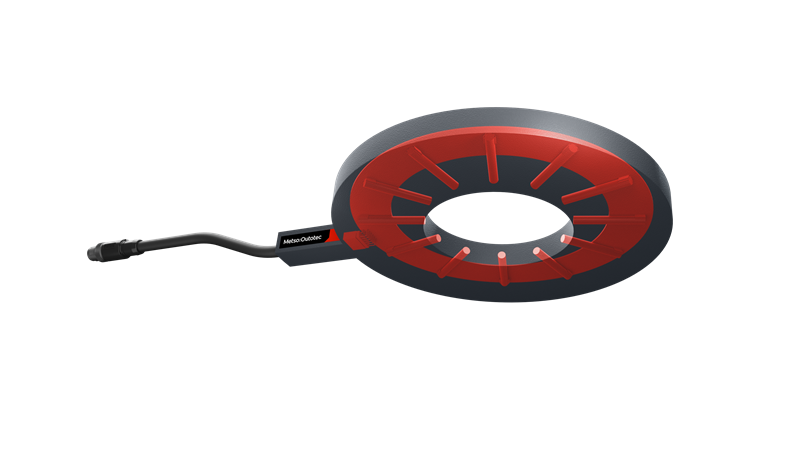

Metso Outotec launches CycloneSense monitoring technology

Metso Outotec has introduced the CycloneSense a smart measurement system to help ensure continuously optimal hydrocyclone operations. The system provides direct, continuous, and reliable online monitoring of the hydrocyclone air core. The company notes that operating conditions in the hydrocyclone process have a direct impact on plant availability and on grinding and flotation circuit efficiency.

“In order to optimize the process, hydrocyclones should be run so that the fraction of water returned to grinding is the smallest amount possible. In order to do that, you need to know when you are approaching the limit of your hydrocyclone’s coarse discharge rate to avoid going too far and ending up with problems, such as roping,” professor emeritus Kari Heiskanen, said in a release. “CycloneSense allows you to see what is happening inside the hydrocyclone and helps to push the limits of the process.”

The CycloneSense technology allows users to visualize the performance inside the cyclone. It enables continuous online measurement of the cyclone’s air core shape, size, and location based on process tomography, thus helping to find and maintain the optimal operating point for the hydrocyclone. In addition, the measurement system helps to detect and prevent potential problem situations, such as roping, where the slurry is not properly separated and instead some of the larger particles are sent to the overflow and directly to the next stage of processing.

Combining CycloneSense with the Metso Outotec PSI particle size analyzer allows easy optimization of the cyclone cluster and grinding circuit. Metso Outotec’s ACT Cyclone Control and Grinding Optimization is designed to take full advantage of the measurement data and to provide continuous benefits to customers.

The CycloneSense measurement system is available for new Metso Outotec hydrocyclones and existing hydrocyclone installations. As an optional service, Metso Outotec also provides Life Cycle Services with remote monitoring.

Key benefits of CycloneSense include continuous, online measurement of hydrocyclone air core shape, size, and location; prevention of problem situations, such as roping, and increased uptime and production; and automated hydrocyclone system control and performance optimization.

CycloneSense monitoring technology is part of Metso Outotec’s Planet Positive offering.

For more information, visit www.MOGroup.com.

Comments