[caption id="attachment_1003743106" align="aligncenter" width="350"]

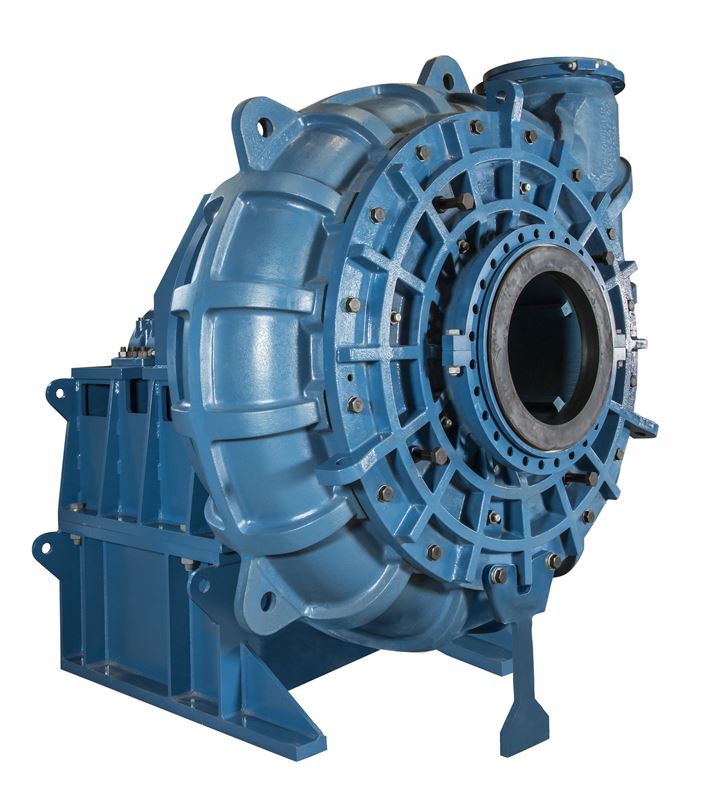

The MD-MDM650 discharge pump Credit: Metso Outotec

The MD-MDM650 discharge pump Credit: Metso Outotec[/caption]

Metso Outotec has introduced a full line of mill discharge pumps for reliable and efficient slurry handling in minerals processing.

”Slurry handling is vital in maximizing a minerals processing plant’s productivity and efficiency,” Diwakar Aduri, product manager, MD pumps at Metso Outotec, said in a release. “Insufficient slurry handling may bring the whole plant to a halt or lead to inefficiencies in different parts of the process, causing major production losses. A large concentrator plant can have up to 150 different types of pumps in operation. Metso Outotec mill discharge (MD) pumps are robust and have been designed to operate reliably in highly abrasive environments, providing optimal solutions for each part of the process.”

Keeping the industry’s ever evolving needs in mind, the Metso Outotec MD-series pumps offer outstanding uptime and sustained efficiencies. These pumps have been designed for efficient operation and longest wear life to match the mill’s uptime.

Metso Outotec’s MD series pumps come in two tailored solutions, MDM and MDR. The MDM (mill discharge metal) pumps are available in size ranges of 250 to 700 millimetres, the MDR (mill discharge rubber) models also come in size ranges of 250 to 700 millimetres. Both pump types are suited for heavy-duty use in concentrator plants, offering excellent resistance to abrasion and erosion.

When selecting a slurry pump for a mine, one should look for the most robust and technologically advanced pump in terms of performance, wear resistance, uptime and total cost of ownership. Metso Outotec offers analysis service for this purpose with a detailed summary report and guidance on how to minimize total cost of ownership. It is also possible to check an initial fit using Metso Outotec’s 3D models available on the

webpage.

To find out more about the Metso Outotec MD Series pumps,

click here.

The MD-MDM650 discharge pump Credit: Metso Outotec[/caption]

Metso Outotec has introduced a full line of mill discharge pumps for reliable and efficient slurry handling in minerals processing.

”Slurry handling is vital in maximizing a minerals processing plant’s productivity and efficiency,” Diwakar Aduri, product manager, MD pumps at Metso Outotec, said in a release. “Insufficient slurry handling may bring the whole plant to a halt or lead to inefficiencies in different parts of the process, causing major production losses. A large concentrator plant can have up to 150 different types of pumps in operation. Metso Outotec mill discharge (MD) pumps are robust and have been designed to operate reliably in highly abrasive environments, providing optimal solutions for each part of the process.”

Keeping the industry’s ever evolving needs in mind, the Metso Outotec MD-series pumps offer outstanding uptime and sustained efficiencies. These pumps have been designed for efficient operation and longest wear life to match the mill’s uptime.

Metso Outotec’s MD series pumps come in two tailored solutions, MDM and MDR. The MDM (mill discharge metal) pumps are available in size ranges of 250 to 700 millimetres, the MDR (mill discharge rubber) models also come in size ranges of 250 to 700 millimetres. Both pump types are suited for heavy-duty use in concentrator plants, offering excellent resistance to abrasion and erosion.

When selecting a slurry pump for a mine, one should look for the most robust and technologically advanced pump in terms of performance, wear resistance, uptime and total cost of ownership. Metso Outotec offers analysis service for this purpose with a detailed summary report and guidance on how to minimize total cost of ownership. It is also possible to check an initial fit using Metso Outotec’s 3D models available on the

The MD-MDM650 discharge pump Credit: Metso Outotec[/caption]

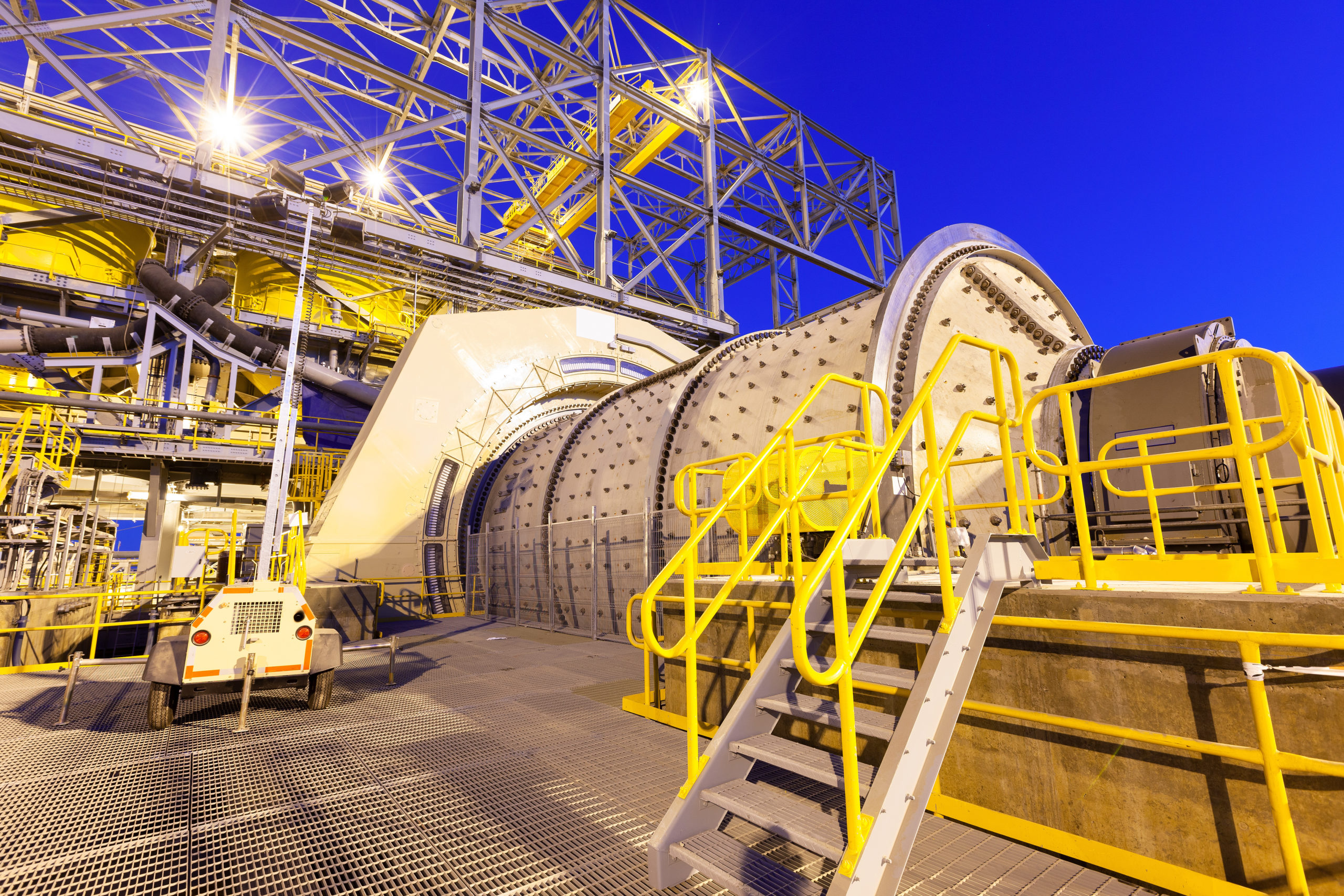

Metso Outotec has introduced a full line of mill discharge pumps for reliable and efficient slurry handling in minerals processing.

”Slurry handling is vital in maximizing a minerals processing plant’s productivity and efficiency,” Diwakar Aduri, product manager, MD pumps at Metso Outotec, said in a release. “Insufficient slurry handling may bring the whole plant to a halt or lead to inefficiencies in different parts of the process, causing major production losses. A large concentrator plant can have up to 150 different types of pumps in operation. Metso Outotec mill discharge (MD) pumps are robust and have been designed to operate reliably in highly abrasive environments, providing optimal solutions for each part of the process.”

Keeping the industry’s ever evolving needs in mind, the Metso Outotec MD-series pumps offer outstanding uptime and sustained efficiencies. These pumps have been designed for efficient operation and longest wear life to match the mill’s uptime.

Metso Outotec’s MD series pumps come in two tailored solutions, MDM and MDR. The MDM (mill discharge metal) pumps are available in size ranges of 250 to 700 millimetres, the MDR (mill discharge rubber) models also come in size ranges of 250 to 700 millimetres. Both pump types are suited for heavy-duty use in concentrator plants, offering excellent resistance to abrasion and erosion.

When selecting a slurry pump for a mine, one should look for the most robust and technologically advanced pump in terms of performance, wear resistance, uptime and total cost of ownership. Metso Outotec offers analysis service for this purpose with a detailed summary report and guidance on how to minimize total cost of ownership. It is also possible to check an initial fit using Metso Outotec’s 3D models available on the

Comments