Martin Engineering highlights safe conveyor design

Conveyors are among the most dynamic and potentially dangerous equipment in bulk handling, and the operational basics of belt conveyor systems are often a mystery to many employees. This knowledge gap creates a safety gap, and safety professionals agree that designing the hazard out of the component or system is the most cost-effective and durable solution.

Martin Engineering encourages forward-thinking designs that exceed compliance standards and enhance an operator’s ability to incorporate future upgrades cost-effectively through a modular approach. This method alleviates several workplace hazards, minimizes cleanup and maintenance, reduces unscheduled downtime, and extends the life of the belt and the system.

To meet the demands for greater safety and improved production, some manufacturers have introduced equipment designs that are not only engineered for safer operation and servicing but also reduced maintenance time. An example is the Martin QC1 cleanerHD/XHD STS (safe to service) primary cleaner and the Martin SQC2S STS secondary cleaner, designed so the blade cartridge can be pulled away from the belt for safe access and replacement by a single worker.

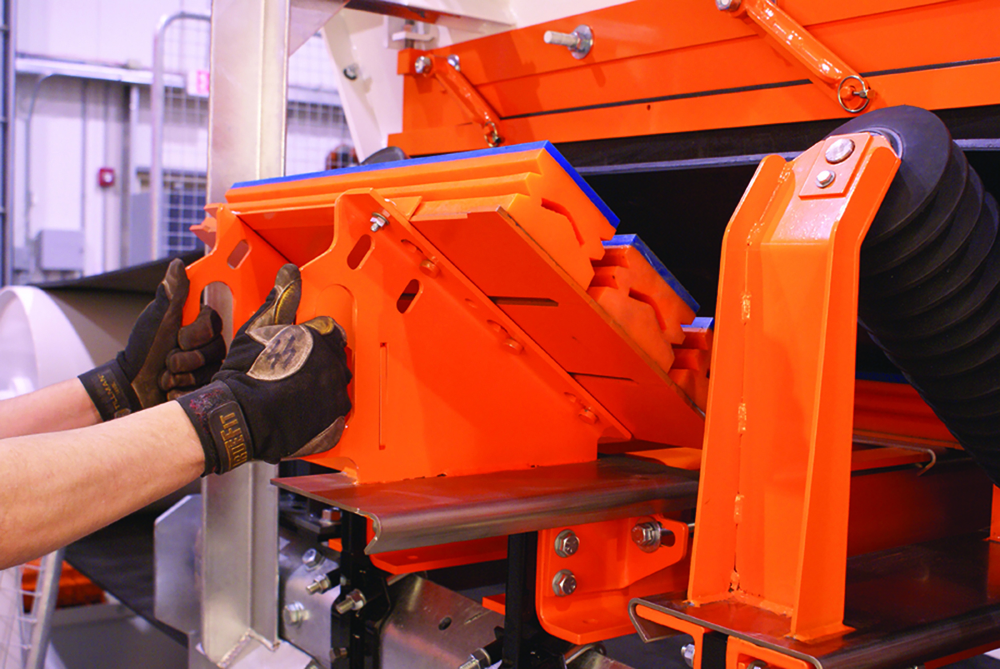

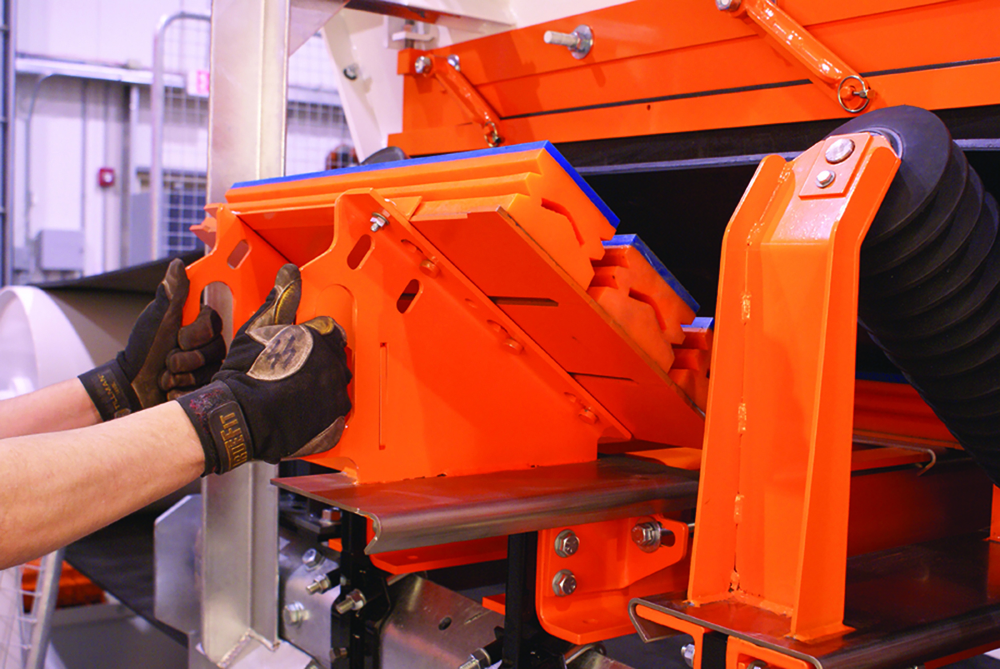

The same slide-out technology has been applied to impact cradle designs. Systems like the Martin slider cradle are engineered so operators can work on the equipment safely, without breaking the plane of motion. External servicing reduces confined space entry and eliminates reach-in maintenance while facilitating faster replacement. The result is greater safety and efficiency, with less downtime.

An example of a safer belt cleaner is the CleanScrape, which received the Australian Bulk Handling award in the innovative technology category for its design and potential benefits. The revolutionary patented design reduces the need for bulky urethane blades altogether. It delivers extended service life, low belt wear, significantly reduced maintenance, improved safety, and lower cost of ownership.

Although the policy is generally not explicitly stated by companies, the “low-bid process” is usually an implied rule that is baked into a company’s culture. It encourages bidders to follow a belt conveyor design methodology that gets the maximum load on the conveyor belt with the minimum compliance to regulations using the lowest price materials, components, and manufacturing processes available.

When companies buy on price, the benefits are often short-lived, and costs increase over time, eventually resulting in losses. But when purchases are made based on the lowest long-term cost (lifecycle cost), benefits usually continue to accrue and costs are lower, resulting in net savings over time.

Engineering safer conveyors is a long-term strategy. Although design absorbs less than 10% of the total budget of a project, it is essential to consider lifecyclecosts rather than just initial purchase price when making decisions about conveyor equipment.

For more information, visit www.Martin-Eng.com.

Comments