[caption id="attachment_1003725529" align="aligncenter" width="491"]

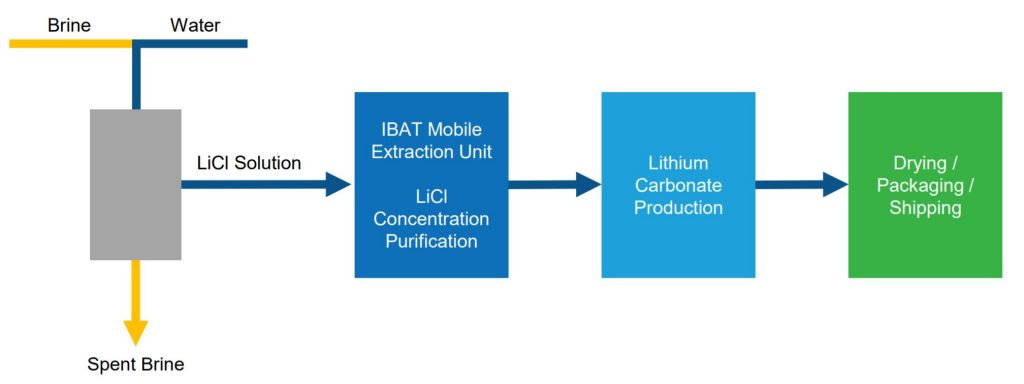

A quick look at IBAT’s oilfield lithium extraction process. (Image: International Battery Metals)

A quick look at IBAT’s oilfield lithium extraction process. (Image: International Battery Metals)[/caption]

VANCOUVER –

International Battery Metals (IBAT) has completed the second phase engineering study, design and cost analysis for a planned lithium extraction system. It could be piloted next year.

This plant will produce high purity 40% lithium chloride in commercial quantities. The equipment is mobile, supplied in containerized units.

IBAT says its process provides environmental advantages.

Unlike evaporative processes that can damage sensitive salars, IBAT's process does not evaporate water from the brine. Instead, it extracts lithium from the brine and returns it back to the resource. This maintains the resource water balance and protects delicate ecosystems.

IBAT's process uses no solvents or foreign chemicals that will alter the brine chemistry. This is important to the protection of resource ecology. Returning brine to the resource could be questionable if it is contaminated with organic solvents or other chemicals that are not native to the ecosystem.

IBAT's process is designed to recycle approximately 95% of its process water. The water recovery system will be particularly important in desert areas and where potable ground water is in short supply.

Learn more about this new technology at

www.iBatteryMetals.com.

A quick look at IBAT’s oilfield lithium extraction process. (Image: International Battery Metals)[/caption]

VANCOUVER – International Battery Metals (IBAT) has completed the second phase engineering study, design and cost analysis for a planned lithium extraction system. It could be piloted next year.

This plant will produce high purity 40% lithium chloride in commercial quantities. The equipment is mobile, supplied in containerized units.

IBAT says its process provides environmental advantages.

Unlike evaporative processes that can damage sensitive salars, IBAT's process does not evaporate water from the brine. Instead, it extracts lithium from the brine and returns it back to the resource. This maintains the resource water balance and protects delicate ecosystems.

IBAT's process uses no solvents or foreign chemicals that will alter the brine chemistry. This is important to the protection of resource ecology. Returning brine to the resource could be questionable if it is contaminated with organic solvents or other chemicals that are not native to the ecosystem.

IBAT's process is designed to recycle approximately 95% of its process water. The water recovery system will be particularly important in desert areas and where potable ground water is in short supply.

Learn more about this new technology at

A quick look at IBAT’s oilfield lithium extraction process. (Image: International Battery Metals)[/caption]

VANCOUVER – International Battery Metals (IBAT) has completed the second phase engineering study, design and cost analysis for a planned lithium extraction system. It could be piloted next year.

This plant will produce high purity 40% lithium chloride in commercial quantities. The equipment is mobile, supplied in containerized units.

IBAT says its process provides environmental advantages.

Unlike evaporative processes that can damage sensitive salars, IBAT's process does not evaporate water from the brine. Instead, it extracts lithium from the brine and returns it back to the resource. This maintains the resource water balance and protects delicate ecosystems.

IBAT's process uses no solvents or foreign chemicals that will alter the brine chemistry. This is important to the protection of resource ecology. Returning brine to the resource could be questionable if it is contaminated with organic solvents or other chemicals that are not native to the ecosystem.

IBAT's process is designed to recycle approximately 95% of its process water. The water recovery system will be particularly important in desert areas and where potable ground water is in short supply.

Learn more about this new technology at

Comments