Linatex premium rubber: A century of abrasion defence from Weir Minerals

Linatex premium rubber, a product of Weir Minerals Malaysia, is celebrating its 100th anniversary as the industry leader in abrasion defence. The red rubber is known for its resilience, strength, and resistance to wear and abrasion, and has been field-tested in mine sites for a century. It is the mining industry’s preferred first line of defence against abrasion for expensive capital equipment.

Brandon Greer, processing maintenance supervisor at Capstone’s Pinto Valley mine recommends Linatex rubbers for their phenomenal life in comparison to other products. Akhbayar Enkhsaikhan, concentrator maintenance manager at the Oyu Tolgoi mine, says that it significantly reduces material costs associated with frequent change outs and enables them to produce more copper.

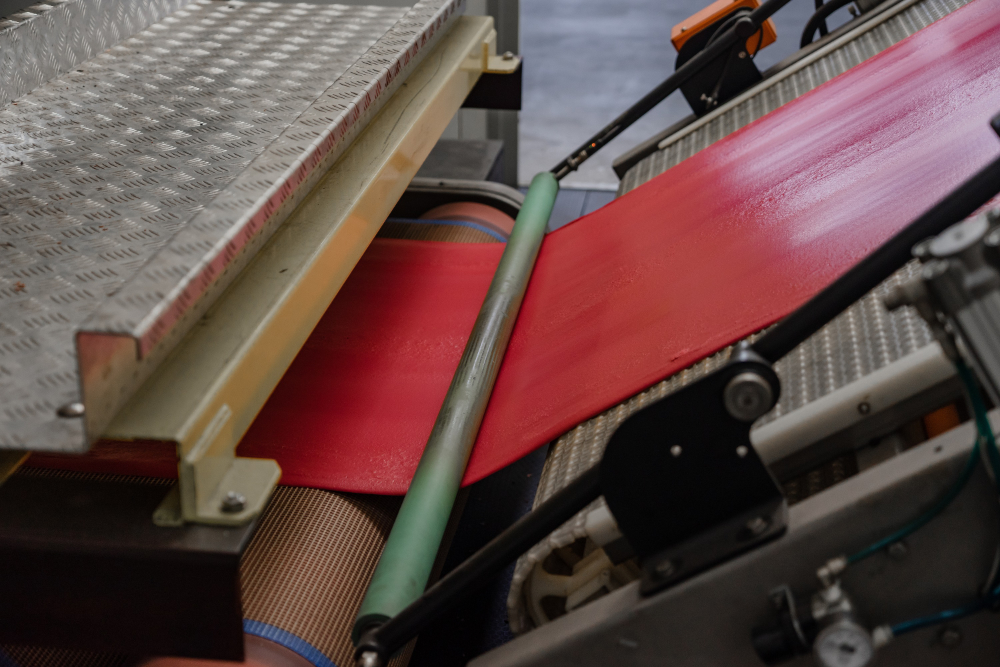

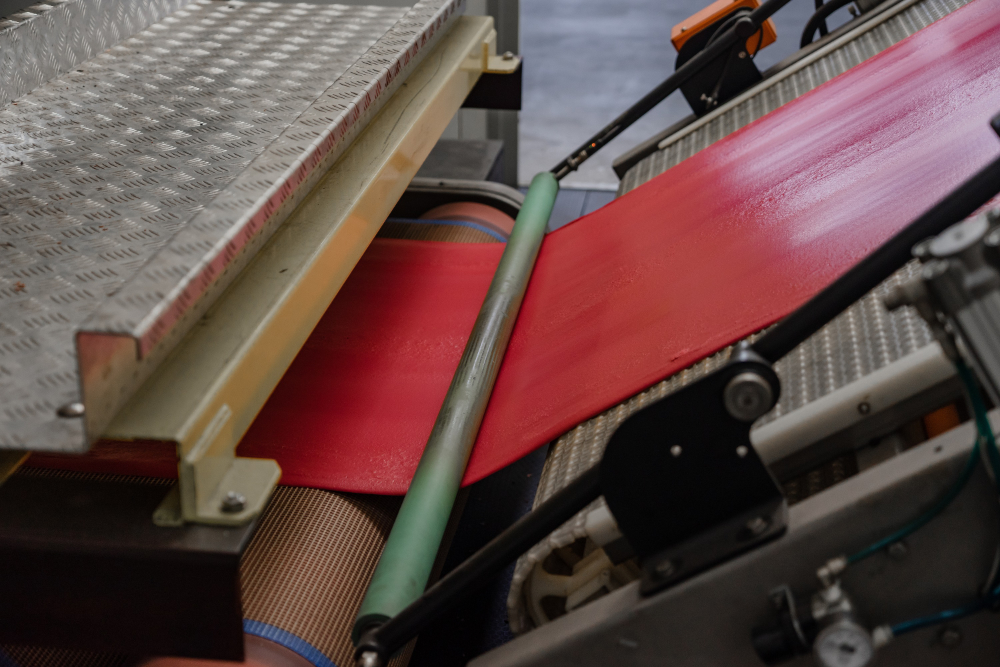

Weir Minerals Malaysia is the sole producer of Linatex premium rubber in the world and is dedicated to meeting customer demand and providing advanced solutions. The rubber manufacturing facility in Batu Caves, Malaysia, has been expanded to include a new continuous rubber process facility, a new Banbury mixer to manufacture masticated dry rubber, and additional rubber presses to support growth within this area of the business.

The proprietary formula of Linatex premium rubber includes a unique liquid compounding phase which maintains the natural state and characteristics of the 95% natural rubber product. The formula has remained unchanged since it was developed and patented in 1923 by Bernard Wilkinson. To ensure a consistent high-quality product, Linatex premium rubber routinely undergoes rigorous testing throughout the entire manufacturing and delivery process.

Linatex premium rubber is the most sustainably manufactured rubber on the market. The natural and renewable resource (pure latex is 100% sap of the rubber tree) is complemented by sustainable processes, minimal waste, and a renewable solar energy system at the site. Stephen Frendt, managing director Weir Minerals, says that Linatex rubber is a very sustainable product based on 95% natural rubber latex with very little effluent or waste. More broadly across the site, they have implemented a range of sustainability initiatives such as solar panels, rainwater harvesting, and a rubber recycling program.

Charlie Stone, VP of sales and business development, says that they are thrilled to celebrate a century of delivering leading value, performance, and sustainability benefits to their customers around the world. Linatex premium rubber is unparalleled in the industry, and they look forward to another successful 100 years and more.

Learn more about Linatex at www.Linatex100.Weir.

Comments