KSB: The importance of warning plates on pumps

After a recent training course, one of KSB’s participants asked a compelling question. He noted that the training had emphasized the importance of the warning plates GIW Industries affixes to its slurry pumps. He said some of the plates were missing from his older pumps, and wondered, “Are these plates really necessary?”

Short answer: Yes.

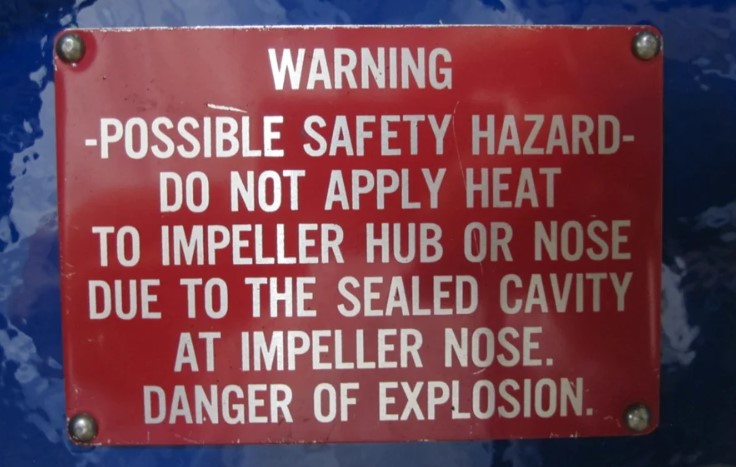

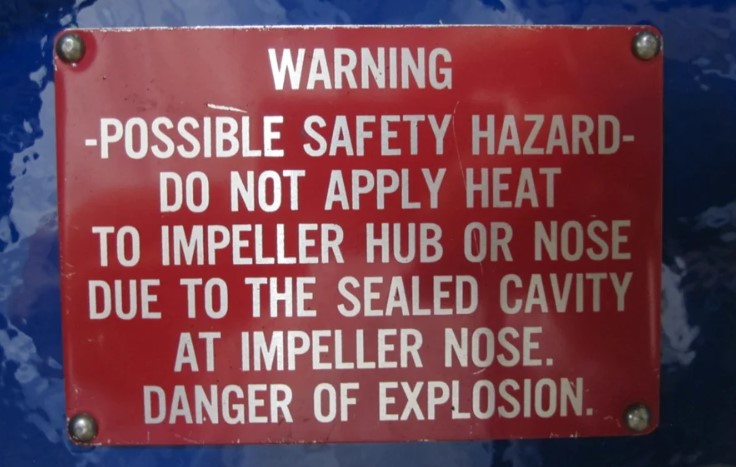

This warning is essential to let maintenance technicians and engineers know the extreme danger of applying heat to the pump impeller. These red warning plates should be attached to your LCC and LSA pump pedestals – two on the LCC and one on the LSA.

Why would you heat an impeller? Sometimes during maintenance, crews find that the impeller is difficult to remove. They might believe heating the impeller will expand in the hub and make the impeller easier to remove.

But heating can actually result in a catastrophic explosion. Never heat the impeller!

Instead, make impeller removal easier by using an impeller release ring or the two-gasket method. Then, use GIW’s handy shaft sleeve lift device for easier shaft sleeve removal.

If you have an older model LCC or LSA pump, check to be sure your warning plates are in place and easy to see.

Make safety your first priority!

Learn more about purchasing the slurry pump that fits your application at www.KSB.com.

Comments