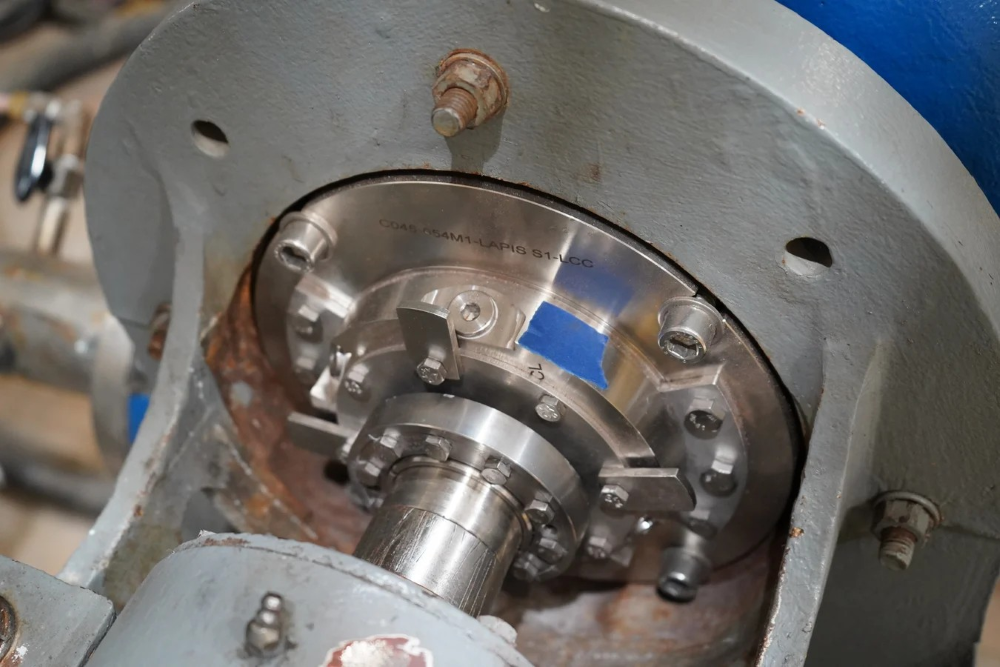

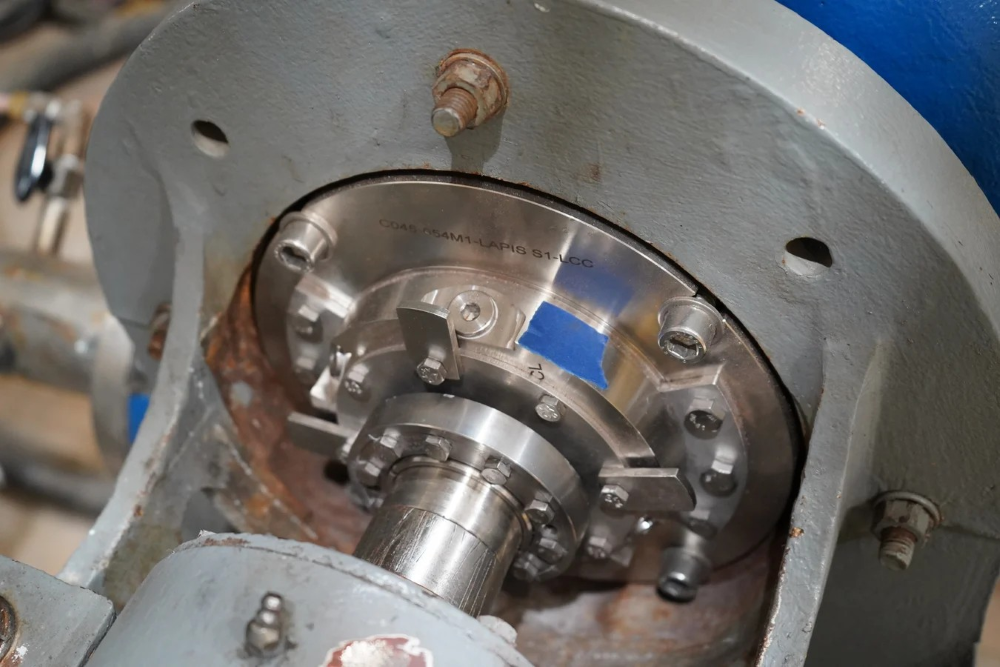

KSB GIW introduces LAPIS seals for slurry pumps

KSB GIW has introduced the LAPIS slurry seal. LAPIS is KSB’s first mechanical seal designed exclusively for GIW slurry pumps for heavy duty slurry service. This product is the result of a collaboration between the product development teams from KSB GIW and KSB Pegnitz.

In early 2023, the company finalized the slurry seal design for the GIW LCC type series. GIW delivered the first LAPIS prototypes in July of that year. As of this publication, the tech designer has already manufactured over 50 LAPIS units in Pegnitz. They have delivered them to KSB factories and customers throughout the world, including the US, Brazil, South Africa, India, and Indonesia. The company reported multiple field installations in service class 2 and 3 slurry applications among these.

In August of 2024, researchers performed comprehensive slurry testing in the KSB GIW test lab. GIW staff reported the team achieved service class four conditions with solids concentrations up to 1.7 SG (or 67% by weight). Additional testing was performed on the test bench in Frankenthal to validate performance at the highest operating speeds with seal face sliding velocities up to and exceeding 15 m/s, also with excellent results.

LAPIS configurations available for the full LCC range include two standard single seal options: LAPIS S with optional water quench and optional internal flush, LAPIS GQ with grease quench and optional internal flush In addition to the established LCC product line, these configurations are also fully developed and configured for sale with the first LCC Gen2 pumps.

Highlights of the KSB LAPIS seal include protected springs, external to the pumping fluid, with solids clearing action provided by the external quench medium, a clamp collar locking mechanism, for maximum torque carrying capacity and ease of adjustment, a “One stop shop” option for customers, backed by KSB’s reputation for quality design, manufacturing, and service, at a highly competitive pricing. Finally, the adapter plate has been eliminated altogether for LCC Gen2, resulting in simplified installation and reduced cost. More information is posted on www.Ksb.com.

Comments