Keep an eye on smelting furnaces with robust camera

Metso Outotec is launching a robust camera to reduce or even eliminate the need to power off or cut the feed to inspect a smelter furnace. Operators can safely monitor conditions inside the furnace in real time and react immediately to situations that would otherwise not necessarily be detected. The furnace camera is a fully integrated solution that is fast and easy to install into new or existing furnaces.

The furnace camera is one of Metso Outotec’s extensive range of smart digital tools that helps increase safety, improve efficiency and availability, and reduce costs in their pyrometallurgical processes.

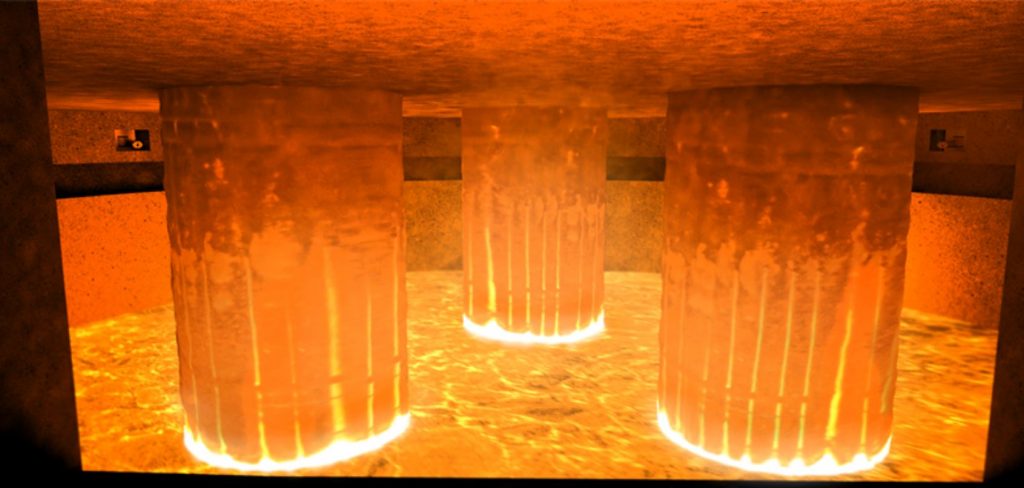

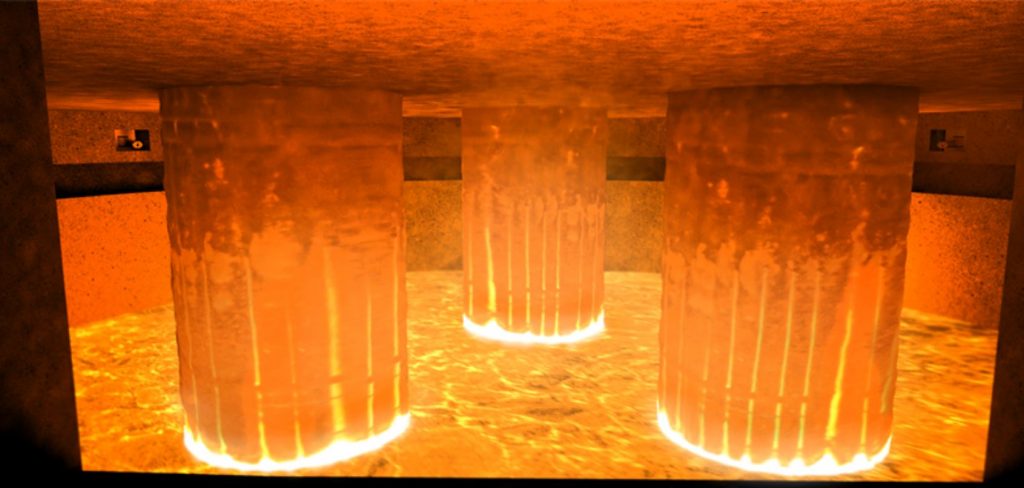

Real-time monitoring of the furnace enables operators to identify potential issues, like water leaks, and to take action to prevent damage. The video feed provides images of internal furnace components, such as electrodes and material feeding. It can measure temperature values from user-specified locations and help find hot spots. Additionally, the operator can identify refractory wear from the images. Additionally, image clarity is not affected by fumes or dust.

The automatic retraction function protects the camera in case of a break in utilities supply. Video, snapshots, and historical trend data can be viewed on the control-room display or used for later analysis.

Metso Outotec supports customers with the commissioning process and provides training for operators and plant management to ensure maximum benefit from the solution. Technical support is also available via an optional remote connection service.

The Furnace Camera is part of Metso Outotec’s Planet Positive offering.

Find out more about the Metso Outotec Furnace Camera on www.MOgroup.com.

Comments