JV Article: SRK Consulting aims to help miners unlock hidden value through pre-concentration

There is a growing interest among mining companies in pre-concentration methods and sorting technologies to improve profitability of their projects.

Pre-concentration can be used to increase the grade of material delivered to processing plants by diverting or removing low-grade fractions that are uneconomic to process. Increasing feed grades may also improve the recovery of target minerals, reduce bottlenecking in processing circuits, and increase throughput.

The technique can also allow separated ores to be fed to different processing circuits. For example, low-grade gold ore can be directed to a heap leach circuit, while higher-grade ore is sent to a carbon-in-leach circuit.

However, the lack of an industry standard or guidelines on assessing pre-concentration opportunities for an orebody are preventing companies from unlocking this hidden potential, say mining experts from SRK Consulting (Canada).

“As ore grades continue to decline, mining companies are increasingly looking for methods like pre-concentration to improve the quality of their mill feed by rejecting the low-grade, poor quality component in the ore being sent to plants,” says Bob McCarthy, a principal mining engineer with SRK.

He says that in the absence of a consistent method for conducting pre-concentration assessments, miners are unable “to effectively evaluate and select feasible pre-concentration options and rapidly-improving technologies,” preventing them from being able “to benchmark and share their results, as is now commonplace for geological and metallurgical analyses."

To address the need for an industry standard, SRK is working with mining companies of all sizes, sorting equipment manufacturers, and testing laboratories to develop robust and comprehensive procedures to better characterize orebodies and evaluate pre-concentration opportunities.

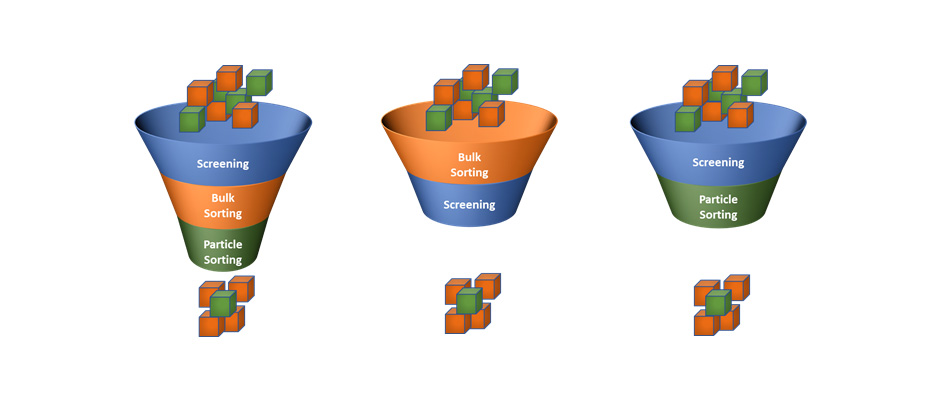

Adrian Dance, a principal metallurgist with SRK, who is working closely with McCarthy to develop these procedures, says that they have defined pre-concentration “as any combination of screening, particle, and bulk sorting when the material is coarse, dry, and transportable by truck or conveyor.”

The work has led to a toolkit consisting of analytical methods and testing protocols that allow mining companies to estimate with greater confidence the economic benefits of pre-concentration. McCarthy and Dance say the results could be used “to support preliminary economics assessments or even up to feasibility study-level evaluations.”

While pre-concentration and sorting techniques can significantly improve feed quality sent to mills by more effectively rejecting low-grade material contained in the ore, McCarthy cautions that not all ores are amenable to pre-concentration.

“The pre-concentration potential of an ore is determined by its heterogeneity,” he explains. “That is, at some scale, the ore must contain discrete higher-grade and lower-grade mineralized zones such as mineralized veins that are hosted by poorly mineralized rock or sulphide breccias containing clasts of unmineralized rock.”

He adds that “as important as finding out that a deposit is amenable to pre-concentration is discovering that the deposit does not lend itself to upgrading opportunities,” noting that learning the latter early in the process “can save significant sampling and testing effort and costs, freeing up resources for identifying other value-adding opportunities for a project.”

Currently, mining companies are required to ship bulk samples of 200 to 300 kg to manufacturers’ facilities for performance testing. These are then sent to laboratories for assaying, which incurs even more costs.

“One of the most significant challenges for pre-concentration evaluation and testing is the collection of samples, particularly small samples, that are representative of not only the overall deposit and mine plan but also what a sorting plant may see as feed at any given time,” says McCarthy.

“Understanding the variation in heterogeneity and the responses to mineral sensing technology around mineral deposits needs to come before any large-scale testing takes place.”

Consequently, SRK’s approach is predicated on first reviewing drill core assays to assess heterogeneity and then to identify suitable intervals exhibiting heterogeneity patterns. Half-core samples of 30 to 50 kg are then collected and sent for testing.

Dance says that these samples are evaluated for particle size distributions (after applying low specific comminution energy), mineral deportment to different size fractions, mineral sensing amenability, and response ranking. “The test work results are then incorporated into reserve block models and mine plans as the basis for economic analyses.”

SRK is developing a test protocol for pre-concentration that could be included in a mining company’s existing metallurgical program and could “piggyback on hardness testing,” says Dance.

The company, he adds, aims to make the testing “as low-cost as possible, with as many samples tested as possible to improve confidence in understanding variability.”

“In the near future, we envision smaller-scale, batch multi-sensor units in commercial labs, negating the need to ship samples to and from manufacturer’s testing facilities,” he says.

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by SRK CONSULTING and produced in co-operation with The Northern Miner. Visit www.srk.com for more information.

Comments