JV Article: Hudbay Minerals’ long and successful history in Manitoba continues with its Lalor mine near Snow Lake

The city of Flin Flon in Manitoba has a rich and storied history of mining that began when gold was discovered around Amisk Lake at the start of the 20th century — the first major discovery of gold west of Ontario since the Klondike gold rush of the 1890s.

The focus then shifted to base metals when, according to local legend, in 1915, a prospector named Tom Creighton discovered a massive copper-zinc orebody in the area. He registered the strike under the name Flin Flon after Josiah Flintabbatey Flonatin, a character from a science fiction novel published a decade earlier.

The name stuck, and as prospectors from all over Canada descended on the area, the settlement of Flin Flon emerged as a major mining centre.

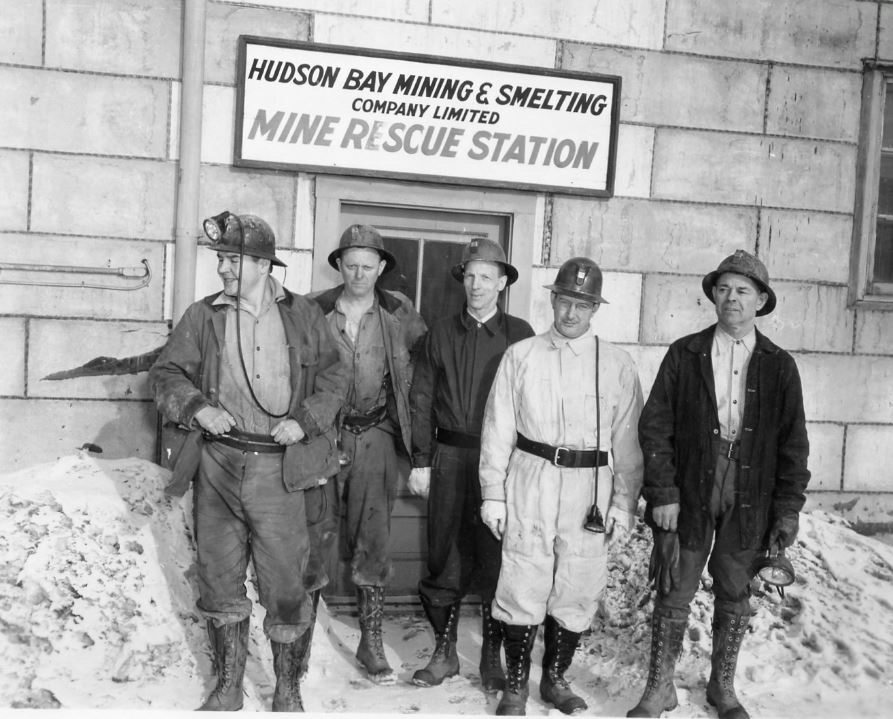

In 1925, the wealthy Whitney family of New York optioned the Flin Flon claim. Two years later, together with Newmont Mining Corp. of New York and the Mining Corp. of Canada, the family founded Hudson Bay Mining & Smelting. In 2004, the company was renamed Hudbay Minerals (TSX: HBM; NYSE: HBM).

The newly-founded company then built the Flin Flon mine, mill, smelter, and a hydroelectric dam to power the mining operations. One of the largest industrial complexes at the time, it opened up northern Manitoba.

The Flin Flon mine went into full production in 1930. Around a decade later, Hudbay was Canada’s second-largest zinc producer, the third-largest producer of copper, and seventh in gold.

For over 90 years, Hudbay and Flin Flon “grew and flourished together,” says Richard Trudeau, the company’s director of human resources, Indigenous, and external affairs.

“Hudbay contributed to the city by providing jobs, opportunities, and community development, and the city provided a home and a tight-knit, supportive community for generations of Hudbay employees.”

Since the first production at Flin Flon, the Flin Flon Greenstone belt has been a prolific source of ore for the company, which has developed and operated 29 mines, most within 80 km of Flin Flon.

However, the last remaining mine in the Flin Flon area, Hudbay’s 777 mine is scheduled for closure later this year.

“We are proud to have called Flin Flon home for nearly a century … and so the decision to bring operations to an end was tough for us but was based on an economic reality,” says Trudeau.

"The 777 mine has seen 18 stellar years of production and has been our flagship operation in Manitoba during that time,” says Rob Carter, Hudbay’s vice president of the company’s Manitoba business unit.

“The mine hosted a very large and rich orebody. Because of this, we took a different approach and constructed a state-of-the-art mine to reflect continual improvements learned from the previous mines we had developed over the years.”

For example, he says the mine employed an auxiliary cage dedicated to transporting workers to and from the underground mine, used a filter press system for removing slimes before pumping water to the surface, and included a maintenance shop for rebuilding equipment underground, eliminating the need to dismantle equipment for transportation to the surface.

“It was also our first mine to deliver paste underground from the mill for backfill and our first to use computer-driven hoists,” he noted.

Carter says Hudbay “left no stone unturned” to find new deposits around the site but was unsuccessful. So, in late 2018, the company made the difficult decision to start planning for the closure of mining operations in Flin Flon.

He says mining at Flin Flon will cease once the mineral reserves at 777 are depleted, with the last tonne of ore scheduled to be hoisted in mid-June, and the mine being safely decommissioned by September 2022, resulting in the permanent closure of the mine and zinc plant. The mill and tailings facility will then be placed on care and maintenance.

While the closing of 777 will substantially reduce Hudbay’s footprint in Flin Flon, the company will continue to look for opportunities in the area and support the community in times of need, says Trudeau. “We are committed to northern Manitoba and look forward to growing, improving, and delivering value in the region for many years to come.”

Hudbay has already invested $80 million to improve the safety of its Flin Flon tailings impoundment system (FFTIS), which will bring it in line with “the highest industry standards,” says Carter, “with the final phase of the project scheduled for completion this year.”

The FFTIS, he notes, has been operating for more than 90 years and holds more than 100 million tonnes of tailings.

He says that results from ongoing metallurgical testing of the tailings will be critical to the reprocessing project's viability. In addition, the company has completed a winter drill program on the tailings facility, with plans for a summer drill program already underway.

"Should the results from these activities prove favourable, then the project could create further economic benefits for the Flin Flon community,” Carter says.

Hudbay is also focused on expanding its Lalor underground gold-zinc-copper-silver mine near Snow Lake, approximately 215 km east of Flin Flon. The mine started commercial production in 2014.

In 2021, the Manitoba operations produced 143,477 oz. of gold and dore, 93,529 tonnes of zinc, 21,657 tonnes of copper, and 1.1 million oz. of silver.

The company has pegged the 2022 production guidance at 150,000 to185,000 oz. of gold, 50,000 to 70,000 tonnes of zinc, 12,000-16,000 tonnes of copper, and 800,000 to 1.1 million oz. of silver.

Further exploration at Lalor also identified higher-grade zones of gold and copper-gold mineralization at depth. The discovery inspired the company to purchase the 1,500-tonne-per-day New Britannia gold mine and mill, approximately 16 km east of Lalor, in 2015.

Following extensive furnishment, production from the mill re-commenced last August.

“The opening of New Britannia was an important and long-awaited milestone for Hudbay,” says Carter. “It marked the beginning of the transition of our Lalor mine to a primary gold operation and created the opportunity for mining of other gold deposits in the Snow Lake area.”

The upgraded facilities at New Britannia “will substantially improve the copper and gold recovery rates,” he says. “We anticipate annual gold production from our Snow Lake operations to average 180,000 ounces of gold over the next six years at industry-low cash costs.”

He noted that this increased gold capacity complements Hudbay’s “industry-leading portfolio of copper projects that will help us deliver the materials needed to transition to a greener, more sustainable economy.”

In line with its history of working closely with the community of Flin Flon, Hudbay is also making substantial investments in Snow Lake.

“We continue to focus on building relationships with local communities and Indigenous groups to provide access to opportunities at our operations,” says Trudeau. He noted that 15% of Hudbay’s workforce comes from surrounding First Nations communities, who “provide valuable support and skills, and a unique perspective and understanding of the land.”

Hudbay's investments in the area "will improve the Snow Lake airport and create more sustainable housing solutions in the Snow Lake community, including two new lakefront subdivisions on Wekusko Lake and Snow Lake that will add 70 lakefront lots,” he says.

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by HUDBAY MINERALS and produced in co-operation with The Northern Miner. Visit www.hudbayminerals.com for more information.

Comments

Richard Walter Olson

Excellent article detailing the fascinating history of the Flin Flon mine and the arc over the 100 year story. I joined the HBM&S Canadian Head Office in Winnipeg 1965 and the Executives and Staff were exemplary people who were dedicated to the company’s success!