JV Article: Fluor announces dedicated critical minerals team

Fluor Corp., (NYSE: FLR) a global engineering, procurement, construction and maintenance company with a legacy spanning over 75 years in mining, has taken a bold step towards meeting the surging demand for critical minerals worldwide. The company has handpicked a team of industry experts dedicated to advancing the vast potential of coveted minerals such as lithium, cobalt, nickel, platinum group metals, rare earth elements and more.

“Critical mineral projects necessitate a distinct execution approach in certain crucial areas. Our regional mining offices hold full responsibility for project execution, but collaborate closely with the Critical Minerals team on all front-end work, for a more effective approach in technology selection, value engineering and execution strategies. This strategic shift will enable us to leverage the expertise and resources of both teams, and drive greater efficiency and success in our project execution efforts.,” said Michael Woloschuk, the team’s Perth, Australia-based executive director.

“Given the continuous advancement of innovative mineral processing technologies this approach gives us significantly better traction on the technology side, which is particularly important for critical mineral projects,” he added.

One notable trait that sets critical mineral clients apart is their relatively recent emergence in the market, typically as smaller scale, single asset developers. As highlighted by Woloschuk, most global lithium projects fall under this category. It is likely that rare earth projects will follow a similar trend. These clients not only find themselves at the nascent stages of their operational setup but are also under immense pressure to accelerate their production timelines to capitalize on the unprecedented pricing levels, particularly for lithium projects. This unique combination of circumstances demands a thoughtful approach in addressing the challenges faced by critical mineral clients.

“A highly specialized critical minerals team can proactively allocate the optimal resources at the outset of any project, collaborating closely with the owner's team, and harnessing the collective strength of our supply chain and project delivery teams to streamline the entire engineering, procurement, and construction process,” said Woloschuk.

“Historically, the average mine can take well over a decade to progress from discovery to production. However, in the midst of the energy transition, waiting that long for the raw materials necessary for renewables infrastructure, electric vehicles, and a broad range of technological devices is not an option.

"With known reserves of several critical minerals insufficient to meet projected demand, time is of the essence in securing supply for these expanding markets and to feed evolving technology clusters beyond Asia. Collectively, we must uncover methods to expedite these projects and quickly advance emerging technologies to unlock value from projects that otherwise may not be economic.”

The development of critical minerals projects involves complex processes, and the involvement of Fluor can help to ensure the success of the project by providing the necessary expertise and support including mitigation of development challenges, environmental and operational risks.

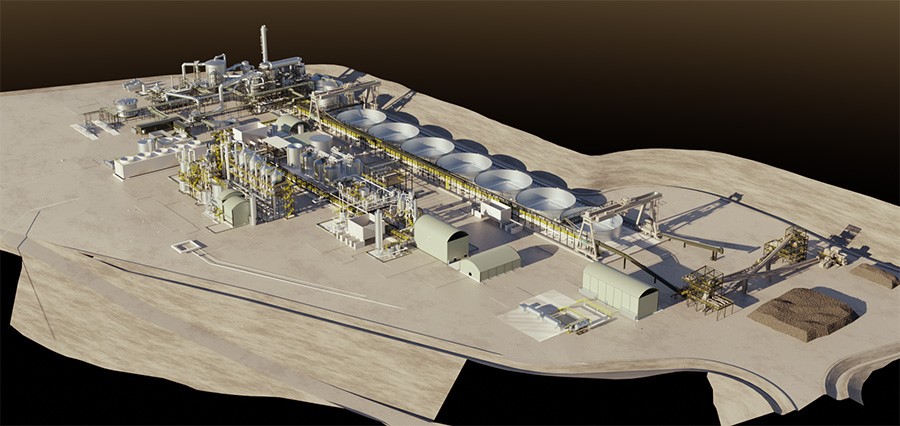

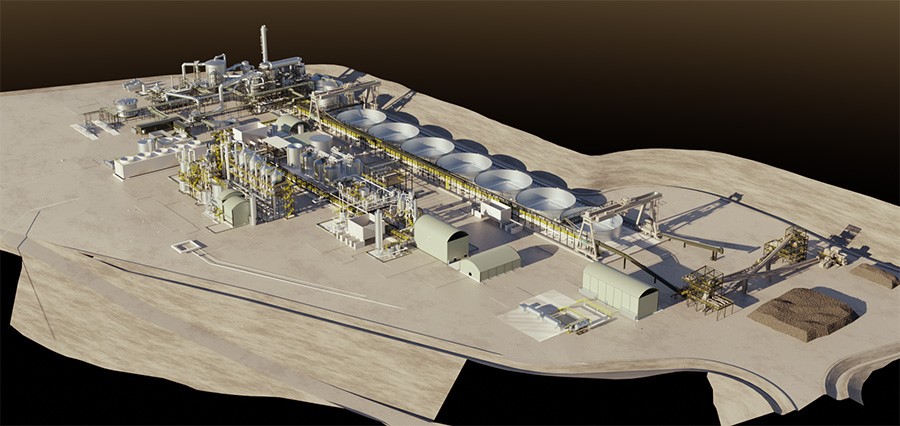

Fluor is currently engaged in several critical mineral projects across various geographic locations. In Western Australia, the company is providing EPCM services for a rare earths refinery. That refinery will produce both light and heavy rare earth oxides such as neodymium, praseodymium, dysprosium, and terbium. These elements are vital to the global electrification process.

Furthermore, Fluor is actively involved in other significant projects such as a lithium concentrator and refinery in Australia. This project is slated to produce 50,000 tonnes of lithium hydroxide annually. In the United States, Fluor accomplished the bankable feasibility study for Ioneer's (NASDAQ: IONR; ASX: INR) Rhyolite Ridge lithium-boron project in Nevada. This project received a conditional commitment for funding from the United States Department of Energy in January. Fluor has also successfully executed several nickel, PGM, and polymetallic projects worldwide.

“Over the past 25 years, our team has successfully completed close to 50 base and precious metal concentrator projects, valued at approximately $70 billion," shared Woloschuk. "Our portfolio includes notable flagship projects spanning the Americas, Africa, Asia, and Australia, and we are rapidly expanding our footprint in Europe. Fluor has been executing some of the largest, most complex copper and iron ore projects coming into production in Peru, Chile, Australia, and Botswana. In Africa and Europe, we are working on bauxite, critical minerals, copper, and gold projects.”

The Fluor Critical Minerals team is fully integrated in the Mining & Metals business line. With a global presence, the team operates from regional offices located in Australia, North America, South America, and Africa. Predominantly composed of process engineers, the team boasts a wealth of expertise in established technologies in mineral processing and across hydrometallurgical and pyrometallurgical flowsheets, as well as emerging technologies such as direct lithium extraction and nano-filtration. Furthermore, the company is actively expanding the team's subject matter expertise with a specific focus on critical mineral projects.

Fluor has decades of experience in mining and possesses critical skill sets that give them deep reach into the entire value chain. Expertise in material handling and water treatment are some examples of the broader capabilities within the company that allow them to deliver an end-to-end solution. Fluor's critical minerals team has the necessary expertise to deliver critical minerals projects, which are crucial for the low carbon future the world is transitioning towards. In addition to technical expertise, Fluor has a proven track record of delivering projects safely, on time, and within budget.

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by Fluor Corporation, and produced in co-operation with The Northern Miner. Visit www.fluor.com for more information.

Comments