Hudbay looks to tailings reprocessing as 777 mine winds down

After 90 years of mining in Flin Flon, Man., Hudbay Minerals’ (TSX: HBM; NYSE: HBM) last operation in the area, the 777 zinc-copper underground mine, will process its last ore this year.

But the company’s tailings facilities - which store more than 100 million tonnes of material - will live on.

While tailings are doubtless a liability, Hudbay is investigating the possibility of turning the mining waste into an asset through tailings reprocessing.

“We've been depositing tailings for the last 90 years with technology that is not as good as what is available today,” said Robert Assabgui, vice-president of the Manitoba Business Unit at Hudbay. “As a result, we believe there's a significant amount of metal in these tailings.”

Assabgui says recoveries at 777 were in the range of 85% for copper and zinc, and as low as 55-65% for gold and silver. The next step will be to understand the mineral inventory in the tailings. A drill program is planned for this winter, and processing work is already under way on previously collected samples. It will take several years to suss out the potential, beginning with a scoping study planned for this year. Assuming positive results, a prefeasibility study and detailed engineering work would follow.

Reprocessing of the tailings would not only extract value from the facility, it would also benefit the environment. Even though it wouldn’t substantially reduce the volume of tailings to be redeposited, the separation of the acid-generating tailings alone would be an environmental positive.

“Reprocessing of tailings is truly our best ESG project in Manitoba,” Assabgui told Canadian Mining Journal.

“These tailings are acid generating and our closure plan and costs reflect this. If we can reprocess the tailings to extract the valuable minerals that were left behind, reap the tailings in a manner that the acid generating tailings are separated from the non-acid generating tailings, and do it in a manner that keeps the acid-generating tailings submerged, then we have the ability to take this liability and turn it into an economic benefit for all of our stakeholders and improve the environmental footprint for the future.”

The existing mill would need to be modified and new equipment added to achieve the grind size needed to extract more metals from the material. “This is really about getting to an ultra-fine grind, which is possible with today's technology to liberate the different minerals, and also potentially having to leach the precious metals to recover them.”

Assabgui says it’s still too early to know what the two streams would look like or if dry stacking would be an option.

While Hudbay works to figure out the logistics and economics of a potential tailings reprocessing operation, the Flin Flon processing plant will be put on care and maintenance.

Assabgui, a mining engineer with 30 years of experience, says the plan is similar to what Hudbay did with its acquisition of the New Britannia mill near Snow Lake, located about 200 km east of Flin Flon by road.

"That facility was on care maintenance when we purchased it. It took us several years to define the gold potential at the Lalor deposit, then we refurbished the mill and built a new flotation facility, and today we're producing gold in Snow Lake. It's no different here in Flin Flon, we're on the same sort of path and timelines.”

Hudbay will also be completing a three-year, $80-million plan to increase the safety of the tailings facilities this year.

Hudbay follows the Mining Association of Canada’s Toward Sustainable Mining (TSM) and Canadian Dam Association guideline on tailings facilities. The company's multi-layered approach to ensuring dam safety includes inspections carried out every five years, with oversight provided by an independent peer review board, the owners’ team, and the engineer of record.

But in the wake of tailings dam failures in the 2010s (Fundao dam in Brazil in 2015; Mount Polley in B.C. in 2014), Hudbay’s engineer of record began an investigation the stability of the Flin Flon impoundments.

Tailings were originally deposited into Flin Flon Lake, the water body that partially covers the orebody. Over time, more than a dozen ponds were built to contain the tailings.

About two-thirds of the dams (more than a dozen) in the facility were older dams constructed using the upstream method. Many of the recent tailings industry failures have been in upstream dams, which are less expensive to build but can be less stable than downstream or centreline dams. Best practice is now to avoid this method of construction.

“Our engineer of record wanted to understand how those failure mechanisms occurred, and if those could be present in our facilities,” Assabgui said, adding that standards for dam construction have changed during the long life of the Flin Flon facility.

“We completed a very thorough drilling campaign to understand the foundation conditions of the dams back in 2017, and ‘18. From that, we concluded that many of our structures did not meet the factor of safety requirements,” Assabgui says.

“When the orebody was found in Flin, Flon there were no communities in the vicinity,” Assabgui says. “The community grew around our operations, and they're very close to our operations and tailings facilities. If one of the dams were to fail, there would be impact to our communities, either in Flin Flon or Creighton.”

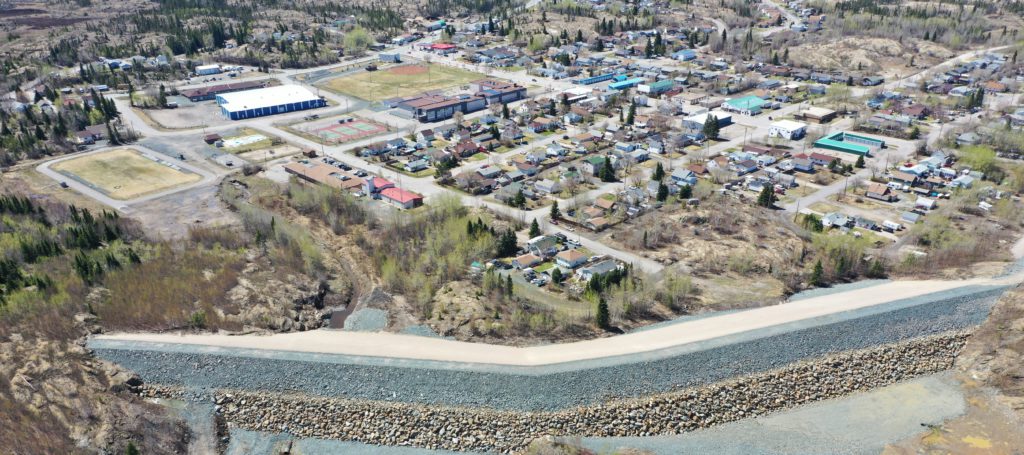

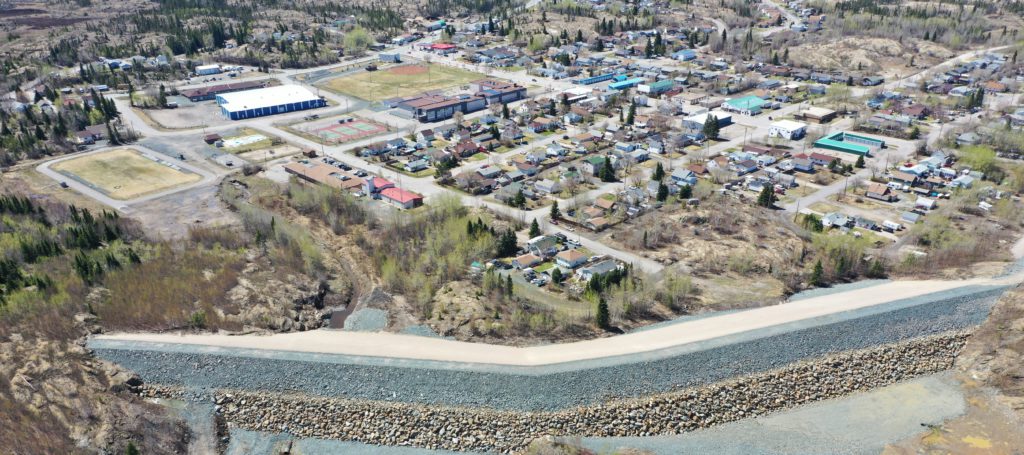

Creighton, Sask., is on the south side of the tailings impoundment, and Flin Flon lies just southeast of the Flin Flon complex (including the 777 mine, tailings facilities and zinc plant).

The first two phases of infrastructure upgrades to the tailings facility have been completed, starting with creating a diversion berm on the south side to redirect material from any potential spill away from residential areas. The second phase involved upgrades to the structure near the Hanson Lake highway and along the southern perimeter of the impoundment. The last phase, which will be complete this year, will involve upgrades to structures that would have less impact on nearby communities if they failed.

If tailings reprocessing proves to be a winner, it would provide welcome revenue that could potentially offset some of the closure costs at Flin Flon. In its third quarter release, Hudbay noted that the overall closure costs (decommissioning and restoration) had increased by $144 million to $322 million – mostly due to a longer post-closure water management period, as well as cost inflation. Twenty-two years were added to the post-closure period to conform with Hudbay’s integrated life of mine plans for its Manitoba operations. Now ending in 2122, the date coincides with 100 years after permanent closure of 777.

According to the release, about 25% of the overall $322 million would be spent in the first 15 years after closure. Three quarters of the total would be spent after the closure of the Snow Lake operations, currently slated for 2037.

Under the current plan, the company will need to build a water treatment plant (budgeted at $33 million) between 2030 and 2042. Until then, the tailings facilities will continue to be used in the clarification process before discharging water to the environment.

The plan is to operate the water treatment plant in perpetuity – or at least until 2122.

However, the closure plan is expected to evolve as it is updated every five years, and an entirely new plan will be created if the tailings reprocessing option is approved.

In addition to defraying closure costs, and reducing the facility’s environmental impact, reprocessing could have another important perk: saving a portion of the nearly 700 jobs set to be lost when 777 closes.

“If we can prove the economic viability of that tailings reprocessing, it would provide employment for many, many years,” Assabgui says.

3 Comments

Lawrence Melis

An interesting article and well presented!

Carie McIntosh

Hi,

Fun Fact, Creighton is in Saskatchewan and Flin Flon is in Manitoba.

Alisha Hiyate

Thanks Carie, we’ve corrected the caption and specified Creighton’s location in the story.