Fleet Space, Talon Metals piloting satellite exploration technology in U.S.

Talon Metals and Fleet Space Technologies are piloting Fleet’s ExoSphere rapid mineral exploration solution at Talon’s exploration projects in Minnesota and Michigan. Talon is exploring for high-grade nickel deposits in the United States to supply the domestic battery supply chain with nickel and other battery materials required in the energy transition.

“Fleet’s technology has the potential to deliver two tantalizing results for geologists like our team of proven nickel hunters – speed and accuracy,” said Talon CEO Henri von Rooyen. “Increased accuracy means less disturbance of the earth as compared to conventional exploration practices. Speed means a faster path to discovering the metallic minerals like nickel that society needs for the energy transition.”

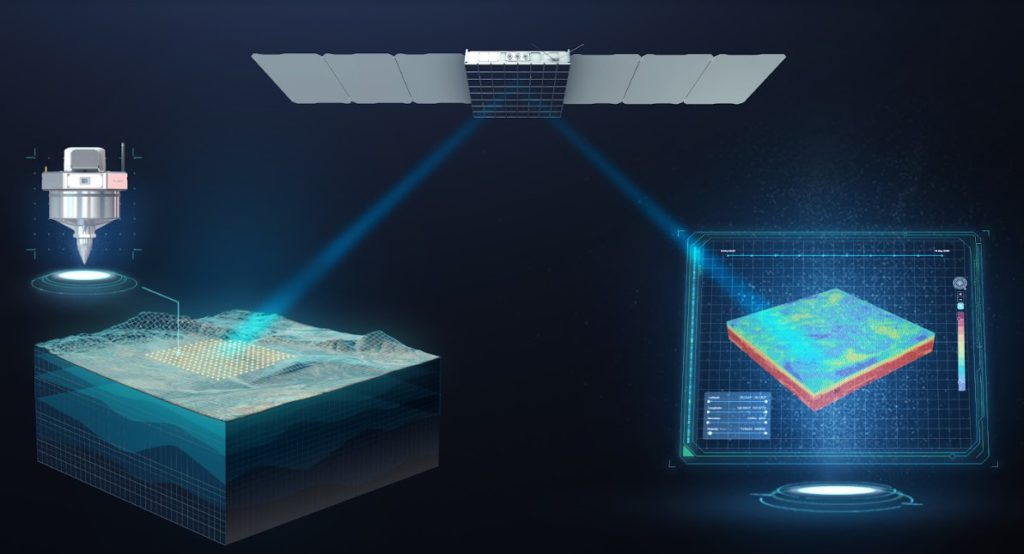

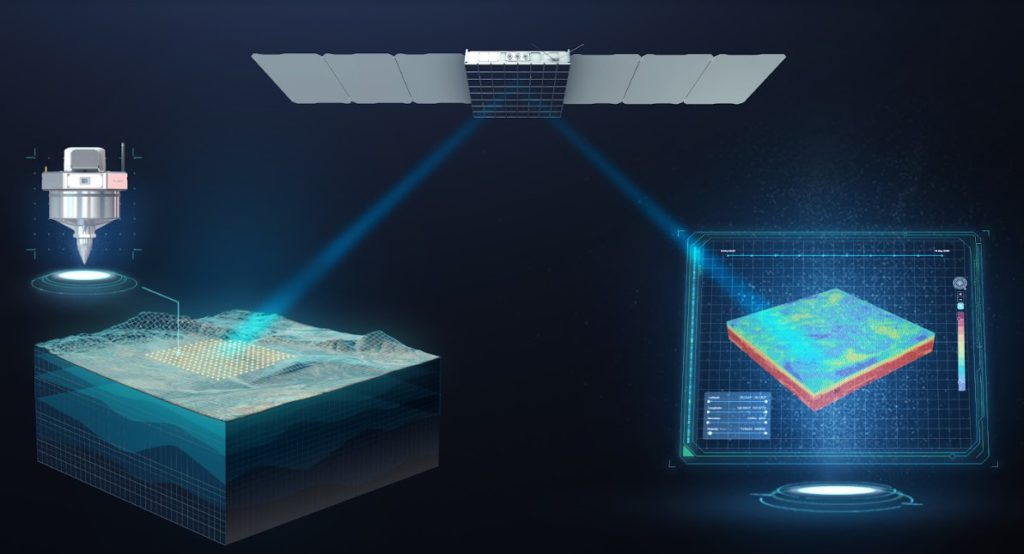

Fleet’s ExoSphere technology scans the ground using an advanced seismic tomography technique, called ambient noise tomography (ANT), where highly transportable devices listen to faint background vibrations from natural and man-made sources. The data is then processed rapidly and transmitted from anywhere in the world through Fleet’s constellation of low earth orbit satellites, recently launched by SpaceX.”

Fleet says it ExoSphere technology can speed up the discovery of vital metals more than one hundred-fold.

Fleet’s rapid exploration solution (ExoSphere) enhances drill program accuracy by scanning a target area with advanced, low-impact ground sensors (known as Geodes) connected through Fleet’s low-power satellite network. The Geodes are up to ten times more sensitive than existing nodal geophones, which increases accuracy and depth of results. Geodes are hand transportable by small teams at surface.

Each wireless, battery-operated Geode contains a sophisticated processing unit, satellite transmitter and seismic sensor. The Geodes use the principles of seismology to map the properties of the Earth’s subsurface from faint background seismic waves - a process known as ANT. Geodes partially process the raw information on site, reducing the data requirement for transmission.

The data from each Geode is rapidly processed and can deliver a full 3D visualization of the subsurface down to 2.0 km depth. A clear, rich image of what resources may be below ground can be generated in as little as four days.

Using a bespoke Fleet-developed system, these visualizations are accessible to view and export anywhere on earth in near real-time. The speed of this imaging now means that thousands of square kilometres of area can be imaged in a fraction of the time of traditional ground-based methods that would currently require drilling rigs to be moved into place.

The data collected from the in-field Geodes is securely pushed to Fleet’s network of low-power small satellites. The satellites then send the data to ground stations to process data using Fleet’s proprietary processing systems delivering a 3D visualization of the area to support critical exploration decisions. This in turn allows teams of geologists like Talon’s team of in-house nickel hunters to make informed decisions on areas of interest much faster than traditional methods.

For additional information on Fleet Space Technologies, please visit the company’s website at www.Fleet.Space.

Comments