Eriez HydroFloat coarse particle flotation system saves energy, water and tailings costs

A recent study based on test results supported by an engineering analysis indicates that installing an Eriez HydroFloat coarse particle flotation (CPF) system in the mill circuit results in a significant decrease in the mill load, cutting power usage in half.

The findings also show that approximately 30% of the total run of mine mill feed can be removed from the circuit prior to conventional flotation, resulting in a 40% decrease of conventional flotation capacity, 30% to 50% reduction in grinding energy and a 30% reduction in tailings management costs.

“What our team learned in the lab is now being implemented in the field,” said Eric Bain Wasmund, VP global flotation business in a release. He added that results could be even more substantial at more remote sites or those with limited water supply.

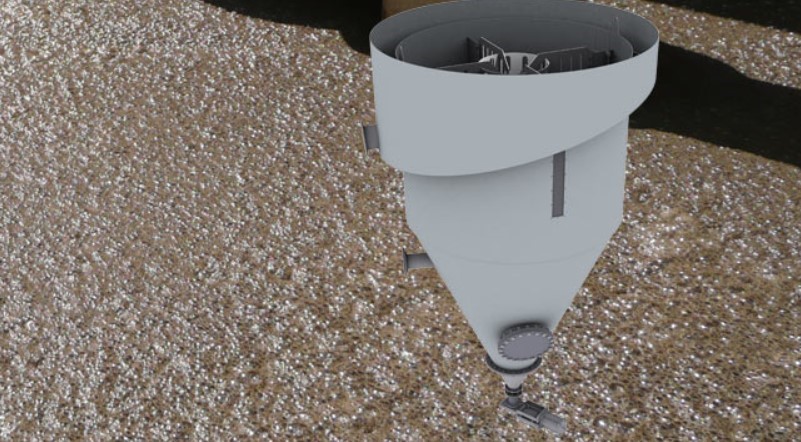

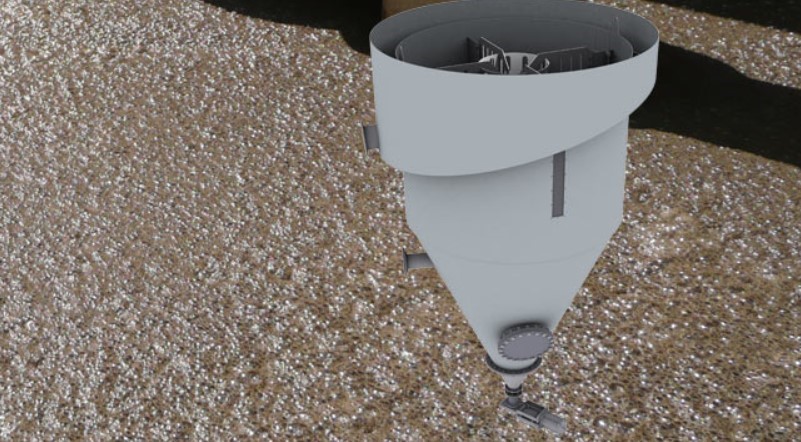

The HydroFloat CPF separator is an aerated fluidized bed (or teeter bed) separator that uses the synergistic effect of combining flotation with gravity concentration, resulting in an outcome that cannot be achieved by either approach alone. In the HydroFloat, the air bubbles that are dispersed by a fluidization system rise through the fluidized bed and attach to the hydrophobic particles, altering their density and rendering them sufficiently buoyant to float and be recovered at the top of the cell.

HydroFloat CPF separators increase bubble-particle collision rates and residence time while decreasing mixing, turbulence and detachment, and buoyancy restrictions. These advantages lead to drastically improved coarse particle recovery.

The HydroFloat CPF can be applied to sulphides, base metals, iron ore, industrial minerals, potash, phosphate, lithium minerals and others. Applications include coarse gangue rejection (preconcentration) and tailings scavenging.

To access technical papers and learn more about HydroFloat CPF Separators, visit EriezNews.com/nr567.

Comments