ILLINOIS – Building on the solid legacy of the MD6420C, the new

Cat MD6310 blasthole drill offers substantial technology, efficiency and productivity improvements. A key advantage of the machine, Cat electronics deliver advanced troubleshooting for efficient drill operation and scalable automation. The building blocks include drill assist, semi-autonomous and remote control operation, and machine health reporting to improve drilling accuracy, reduce fuel consumption and lower total cost of ownership.

[caption id="attachment_1003719290" align="alignleft" width="405"]

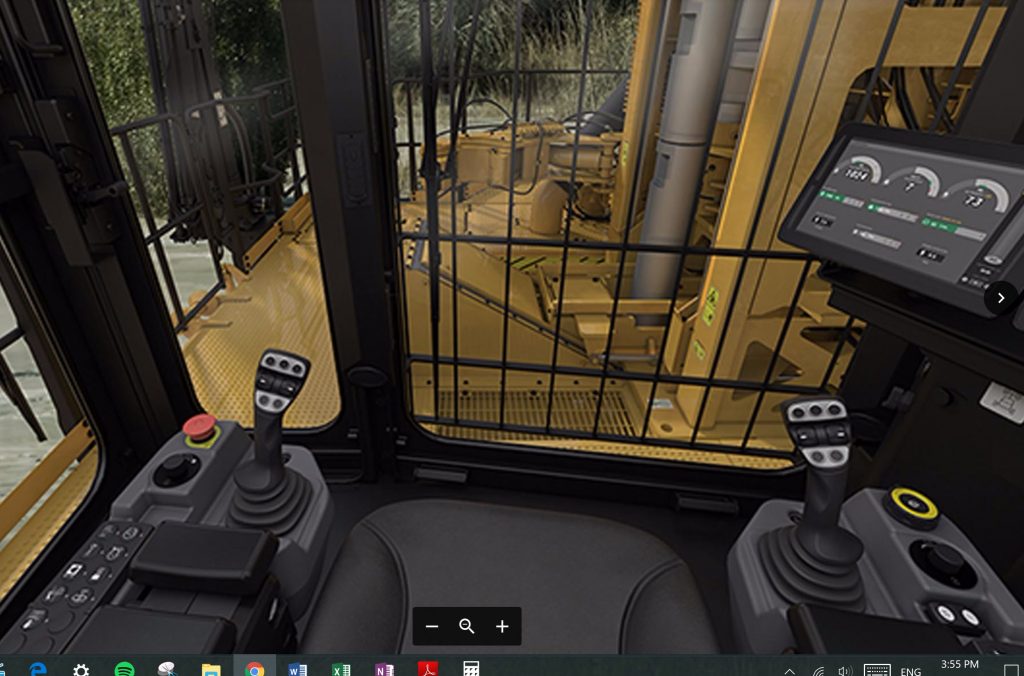

The cab of the MD6310 is as comfortable as any operator could wish.

The cab of the MD6310 is as comfortable as any operator could wish.[/caption]

Ideal for 12- and 15-metre bench heights, the new MD6310 is application-built for efficient single pass drilling down to 13.7 metres or 17.5 metres), depending on mast configuration. Offering up to 30° angle holes for cast blasting, it is ideal for numerous mining applications.

Reaching deeper hole depths than the MD6420C, the MD6310 better matches specific drill and blast requirements when working with electric rope shovels or other loading tools that require a tall and steep muck pile. Standard on the MD6310 is a drill depth indicator, auto level/retract and auto mast, all of which contribute to efficient cycle times.

The MD6310 is fitted with the most advanced technology to improve drilling accuracy. Cat Command for drilling improves remote and autonomous drill operation and serves as the off-board technology foundation of the drill. The Drill Assist option executes all major functions for single pass drilling, automatically adjusting drill power to match the ground conditions. Cat Terrain guides the drill for up to four times greater pattern accuracy. The Terrain logging function ensures all production is timed, mapped and recorded.

Standard Cat Product Link hardware provides machine health and drill data. VisionLink provides users secure access to customizable reports and mapping, giving users equipment data critical for better fleet management.

For complete MD6310 specifications, please visit

Cat.com/drills.

The cab of the MD6310 is as comfortable as any operator could wish.[/caption]

Ideal for 12- and 15-metre bench heights, the new MD6310 is application-built for efficient single pass drilling down to 13.7 metres or 17.5 metres), depending on mast configuration. Offering up to 30° angle holes for cast blasting, it is ideal for numerous mining applications.

Reaching deeper hole depths than the MD6420C, the MD6310 better matches specific drill and blast requirements when working with electric rope shovels or other loading tools that require a tall and steep muck pile. Standard on the MD6310 is a drill depth indicator, auto level/retract and auto mast, all of which contribute to efficient cycle times.

The MD6310 is fitted with the most advanced technology to improve drilling accuracy. Cat Command for drilling improves remote and autonomous drill operation and serves as the off-board technology foundation of the drill. The Drill Assist option executes all major functions for single pass drilling, automatically adjusting drill power to match the ground conditions. Cat Terrain guides the drill for up to four times greater pattern accuracy. The Terrain logging function ensures all production is timed, mapped and recorded.

Standard Cat Product Link hardware provides machine health and drill data. VisionLink provides users secure access to customizable reports and mapping, giving users equipment data critical for better fleet management.

For complete MD6310 specifications, please visit

The cab of the MD6310 is as comfortable as any operator could wish.[/caption]

Ideal for 12- and 15-metre bench heights, the new MD6310 is application-built for efficient single pass drilling down to 13.7 metres or 17.5 metres), depending on mast configuration. Offering up to 30° angle holes for cast blasting, it is ideal for numerous mining applications.

Reaching deeper hole depths than the MD6420C, the MD6310 better matches specific drill and blast requirements when working with electric rope shovels or other loading tools that require a tall and steep muck pile. Standard on the MD6310 is a drill depth indicator, auto level/retract and auto mast, all of which contribute to efficient cycle times.

The MD6310 is fitted with the most advanced technology to improve drilling accuracy. Cat Command for drilling improves remote and autonomous drill operation and serves as the off-board technology foundation of the drill. The Drill Assist option executes all major functions for single pass drilling, automatically adjusting drill power to match the ground conditions. Cat Terrain guides the drill for up to four times greater pattern accuracy. The Terrain logging function ensures all production is timed, mapped and recorded.

Standard Cat Product Link hardware provides machine health and drill data. VisionLink provides users secure access to customizable reports and mapping, giving users equipment data critical for better fleet management.

For complete MD6310 specifications, please visit

Comments