Doré Copper hopes to restart mining in Chibougamau camp

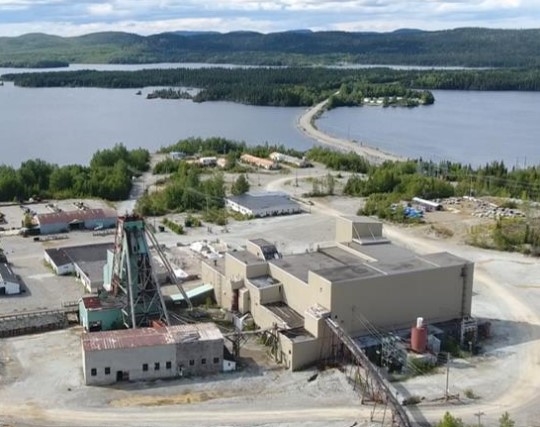

Doré Copper Mining (TSXV:DCMC; OTC:DRCMF; FRA: DCM) has released a positive preliminary economic assessment (PEA) for the restart of mining in the Chibougamau camp in northern Quebec. The PEA outlines a hub-and spoke operation with the high-grade Corner Bay copper-gold deposit as its main underground mine. The Devlin copper deposit and the former Joe Mann gold mine will also feed its Copper Rand mill.

The company sees a base case after-tax net present value with an 8% discount of $193 million and an after-tax internal rate of return of 22.1%. The initial capital requirement of $180.6 million would be repaid in 5.5 years after taxes. Used in the PEA were metal price assumptions of US$3.75/lb. copper and US$1,820/oz. gold with an exchange rate of US$1.00 to C$1.28.

Using spot prices of US$4.20/lb. copper and US$1.854/oz. gold, the Chibougamau project after-tax NPV jumps to $303 million and the after-tax IRR to 29.4%.

The life of the project is 10.5 years during which time Doré Copper would produce 492 million lb. copper and 142,000 oz. gold. The average annual production would be 53.0 million lb. copper-equivalent in concentrate. All-in sustaining costs are estimated to be $2.24/lb. copper-equivalent.

The $180.5-million initial capital cost includes $14.8 million for the Corner Bay mine, $7.0 million for Devlin and virtually nothing for Joe Mann. To refurbish the 1,350-t/d mill and add ore sorting to the flowsheet is estimated to cost $54.2 million. Modernizing the tailings management facility would cost $13.8 million. Engineering, procurement, and construction management (EPCM) would eat up $22.8 million, infrastructure $34.5 million, and owner’s costs $9.9 million. A further $23.6 million is included for contingency.

The PEA estimates the project will need sustaining costs of $402.4 million, over half of which ($247.3 million) will be spent at the Corner Bay mine. The company also plans to set aside $53.6 for reclamation and closure costs.

Doré Copper sees opportunities to extend mining at Chibougamau. Both the Corner Bay and Joe Mann deposits are open at depth. The company is also pursuing several other exploration projects in the camp. The mill has surplus grinding capacity to handle increased ore throughput.

“Our next steps include commencing a feasibility study and submitting permit application with the provincial government. We look forward to working with Ouje-Bougoumou Cree Nation and the towns of Chibougamau and Chapais with the support of the government to advance the restart of the Chibougamau mining camp,” said president and CEO Ernest Mast.

The Corner Bay, Devlin and Joe Mann deposits have measured and indicated resources totalling 3.5 million tonnes grading 2.55% copper (194.0 million lb.) and 0.25 g/t gold (27,000 oz. gold). The inferred resource is 6.9 million tonnes grading 3.04% copper (464.5 million lb.) and 0.83 g/t gold (187,000 oz.).

A bulk sample from Corner processed through the mill in 2008 had recoveries between 93.2% and 93.9% for copper and 78.0% to 83.6% for gold. Over the life of the project, the average grade of the concentrate will be 23.7% copper.

The mill was built in 1959 and expanded twice. Doré Copper does not anticipate using the existing crushing and conveying circuit. Instead, it will install a new crushing circuit and ore sorter at the Corner Bay mine. The pre-concentrated ore will be trucked to the mill and stockpiled. The ore will be conveyed to a new 4.0-metre diameter by 7.2-metre ball mill to be located in the 1984 expansion area of the mill. The new ball mill will replace a rod mill and four ball mills installed when the mill was originally built.

Ball mill discharge will pass through a new hydrocyclones in closed circuit. Cyclone overflow (80% passing 100 microns) will feed the existing flotation circuit, where sequential roughing and scavenging will produce a copper concentrate. The cyclone underflow will feed a pair of gravity concentrators to recover gold. The gold concentrate will then be blended into the copper concentrate.

The peak workforce during operations at the Chibougamau project will be about 320 people.

Additional information about this undertaking is posted on www.DoreCopper.com.

Comments