[caption id="attachment_1003723221" align="aligncenter" width="492"]

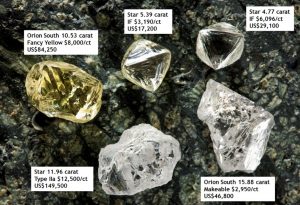

Some of the diamonds recovered during exploration at the Star-Orion project. (Image: Star Diamond)

Some of the diamonds recovered during exploration at the Star-Orion project. (Image: Star Diamond)[/caption]

SASKATCHEWAN –

Star Diamond Corp. of Saskatoon has ordered a 30-t/h bulk sample plant for its Star-Orion project about 60 km east of Prince Albert. The plant will be built by Consulmet Pty in South Africa and shipped in modular, containerized units.

The bulk sample plant has four parts, each with its own control system: 1) a wet front end and feed preparation area; 2) an x-ray transmission (XRT) sorting area; 3) a 10-t/h dense media separator (DMS) area; and 4) a water recycle area. The XRT technology will recover diamonds up to 25 mm with minimum breakage. A secondary crushing circuit will have a high pressure roll crusher (HPRC) to liberate smaller stones.

Washed run of mine, –80 mm kimberlite will be fed to the front-end of the plant. Initial scrubbing and screening sends coarse –80+25 mm kimberlite to the jaw crusher, and removes all –0.85 mm fines using a slotted screen.

Then the –25+12 and –12+6 mm kimberlite fractions will be processed through the XRT sorter in two simultaneous feeds. The XRT sorter accepts are stored in a secure bin for subsequent diamond recovery at a secure off-site facility.

The –25+6 millimetre XRT sorter rejects will report to a secondary HPRC and the crushed product is returned to the primary feed.

The –6+0.85 millimetre kimberlite fraction is processed through the DMS cyclone to prepare a diamond-bearing heavy mineral concentrate.

Plant process water is recovered from various de-watering screens within the plant and the fines thickener, and returned to a recycled water storage facility. Fresh and recycled water are used in the primary plant feed. The underflow from the thickener (–0.85 millimetre) will be sent as residue to an on-site fines management area.

See

www.StarDiamondCorp.com for more information about the Star-Orion project.

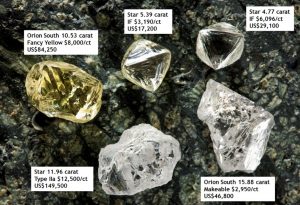

Some of the diamonds recovered during exploration at the Star-Orion project. (Image: Star Diamond)[/caption]

SASKATCHEWAN – Star Diamond Corp. of Saskatoon has ordered a 30-t/h bulk sample plant for its Star-Orion project about 60 km east of Prince Albert. The plant will be built by Consulmet Pty in South Africa and shipped in modular, containerized units.

The bulk sample plant has four parts, each with its own control system: 1) a wet front end and feed preparation area; 2) an x-ray transmission (XRT) sorting area; 3) a 10-t/h dense media separator (DMS) area; and 4) a water recycle area. The XRT technology will recover diamonds up to 25 mm with minimum breakage. A secondary crushing circuit will have a high pressure roll crusher (HPRC) to liberate smaller stones.

Washed run of mine, –80 mm kimberlite will be fed to the front-end of the plant. Initial scrubbing and screening sends coarse –80+25 mm kimberlite to the jaw crusher, and removes all –0.85 mm fines using a slotted screen.

Then the –25+12 and –12+6 mm kimberlite fractions will be processed through the XRT sorter in two simultaneous feeds. The XRT sorter accepts are stored in a secure bin for subsequent diamond recovery at a secure off-site facility.

The –25+6 millimetre XRT sorter rejects will report to a secondary HPRC and the crushed product is returned to the primary feed.

The –6+0.85 millimetre kimberlite fraction is processed through the DMS cyclone to prepare a diamond-bearing heavy mineral concentrate.

Plant process water is recovered from various de-watering screens within the plant and the fines thickener, and returned to a recycled water storage facility. Fresh and recycled water are used in the primary plant feed. The underflow from the thickener (–0.85 millimetre) will be sent as residue to an on-site fines management area.

See

Some of the diamonds recovered during exploration at the Star-Orion project. (Image: Star Diamond)[/caption]

SASKATCHEWAN – Star Diamond Corp. of Saskatoon has ordered a 30-t/h bulk sample plant for its Star-Orion project about 60 km east of Prince Albert. The plant will be built by Consulmet Pty in South Africa and shipped in modular, containerized units.

The bulk sample plant has four parts, each with its own control system: 1) a wet front end and feed preparation area; 2) an x-ray transmission (XRT) sorting area; 3) a 10-t/h dense media separator (DMS) area; and 4) a water recycle area. The XRT technology will recover diamonds up to 25 mm with minimum breakage. A secondary crushing circuit will have a high pressure roll crusher (HPRC) to liberate smaller stones.

Washed run of mine, –80 mm kimberlite will be fed to the front-end of the plant. Initial scrubbing and screening sends coarse –80+25 mm kimberlite to the jaw crusher, and removes all –0.85 mm fines using a slotted screen.

Then the –25+12 and –12+6 mm kimberlite fractions will be processed through the XRT sorter in two simultaneous feeds. The XRT sorter accepts are stored in a secure bin for subsequent diamond recovery at a secure off-site facility.

The –25+6 millimetre XRT sorter rejects will report to a secondary HPRC and the crushed product is returned to the primary feed.

The –6+0.85 millimetre kimberlite fraction is processed through the DMS cyclone to prepare a diamond-bearing heavy mineral concentrate.

Plant process water is recovered from various de-watering screens within the plant and the fines thickener, and returned to a recycled water storage facility. Fresh and recycled water are used in the primary plant feed. The underflow from the thickener (–0.85 millimetre) will be sent as residue to an on-site fines management area.

See

Comments