[caption id="attachment_1003731296" align="aligncenter" width="310"]

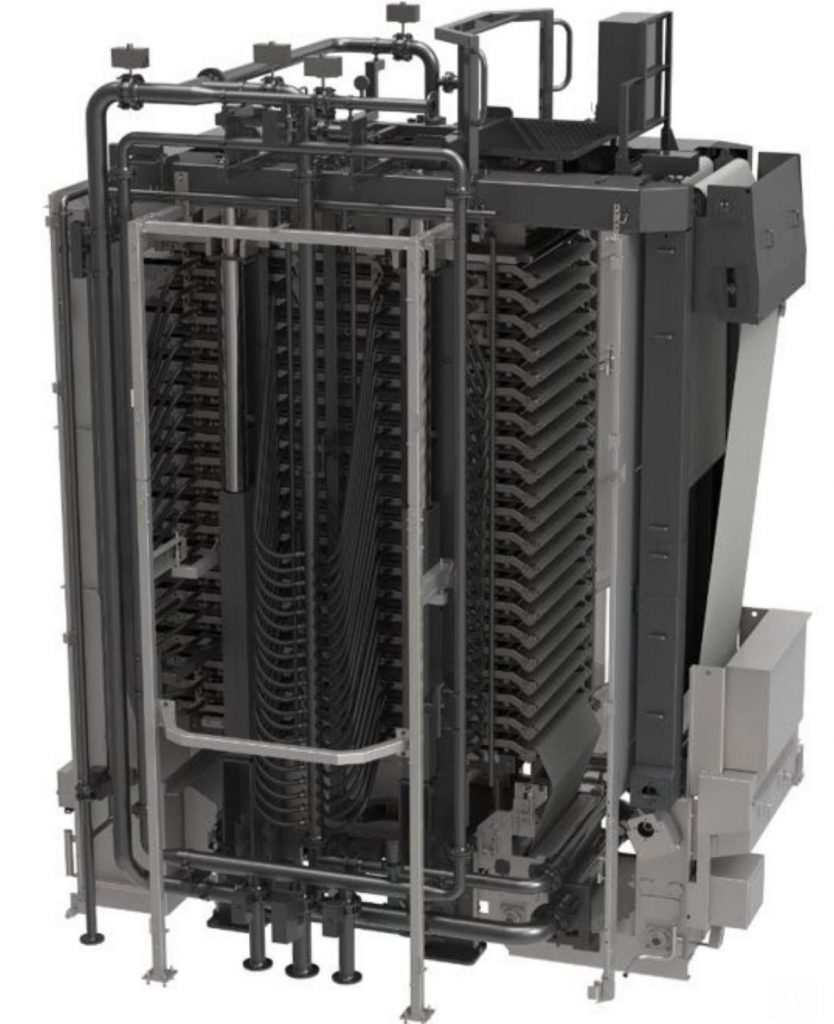

The inner workings of the Outotec Larox double sided pressure filter.

The inner workings of the Outotec Larox double sided pressure filter.[/caption]

HELSINKI – Filtration applications are getting more demanding due to challenging materials, increased cake washing needs, strong acid processes, and finer particles being filtered. There is an increasing need for technologies that can handle these challenges in a reliable and more automated manner.

The new

Outotec Larox PF-DS meets the challenging process requirements and due to the flexible operation, the filter can be used in a wide range of applications, e.g. mineral processing, tailings, battery metal slurries pigments, and food to name a few.

The PF-DS is a tower press filter where the plate pack is composed of polypropylene membrane filter plates stacked on top of each other. The cake forms between the closed filter plates on the top and bottom side of the filtration chamber, hence the term double sided filter.

The new PF-DS combines two proven technologies into one unit. The mechanical operation and frame are shared with the Outotec Larox PF pressure filter while the unique filtration process is powered by the double sided plate pack from Outotec Larox DS filter (earlier known as Hoesch DS).

Thanks to PF-DS now sharing the mechanical design with the PF family, local Outotec service teams are available for technical support and maintenance needs. Likewise, the availability and compatibility of the spare parts is significantly improved compared to earlier technology.

Key features and benefits:

- Excellent handling of difficult and slow-filtering materials

- Guaranteed cake discharge even with challenging material

- Multiple cake washing options lead to superior washing result

- Options for efficient and automatic in situ cleaning (CIP)

- Ability to handle corrosive process conditions

- Fully automatic for consistent results under varying process conditions

Outotec’s comprehensive support services helps customers select the correct filter model, assists with plant design, and ensures efficient and reliable operation with high quality maintenance.

For more information, visit

www.Outotec.com/products/filtration/Larox-pf-ds/.

The inner workings of the Outotec Larox double sided pressure filter.[/caption]

HELSINKI – Filtration applications are getting more demanding due to challenging materials, increased cake washing needs, strong acid processes, and finer particles being filtered. There is an increasing need for technologies that can handle these challenges in a reliable and more automated manner.

The new Outotec Larox PF-DS meets the challenging process requirements and due to the flexible operation, the filter can be used in a wide range of applications, e.g. mineral processing, tailings, battery metal slurries pigments, and food to name a few.

The PF-DS is a tower press filter where the plate pack is composed of polypropylene membrane filter plates stacked on top of each other. The cake forms between the closed filter plates on the top and bottom side of the filtration chamber, hence the term double sided filter.

The new PF-DS combines two proven technologies into one unit. The mechanical operation and frame are shared with the Outotec Larox PF pressure filter while the unique filtration process is powered by the double sided plate pack from Outotec Larox DS filter (earlier known as Hoesch DS).

Thanks to PF-DS now sharing the mechanical design with the PF family, local Outotec service teams are available for technical support and maintenance needs. Likewise, the availability and compatibility of the spare parts is significantly improved compared to earlier technology.

Key features and benefits:

The inner workings of the Outotec Larox double sided pressure filter.[/caption]

HELSINKI – Filtration applications are getting more demanding due to challenging materials, increased cake washing needs, strong acid processes, and finer particles being filtered. There is an increasing need for technologies that can handle these challenges in a reliable and more automated manner.

The new Outotec Larox PF-DS meets the challenging process requirements and due to the flexible operation, the filter can be used in a wide range of applications, e.g. mineral processing, tailings, battery metal slurries pigments, and food to name a few.

The PF-DS is a tower press filter where the plate pack is composed of polypropylene membrane filter plates stacked on top of each other. The cake forms between the closed filter plates on the top and bottom side of the filtration chamber, hence the term double sided filter.

The new PF-DS combines two proven technologies into one unit. The mechanical operation and frame are shared with the Outotec Larox PF pressure filter while the unique filtration process is powered by the double sided plate pack from Outotec Larox DS filter (earlier known as Hoesch DS).

Thanks to PF-DS now sharing the mechanical design with the PF family, local Outotec service teams are available for technical support and maintenance needs. Likewise, the availability and compatibility of the spare parts is significantly improved compared to earlier technology.

Key features and benefits:

Comments