SPRINGFIELD, Ohio – The stand-alone CXT Explorer is an overhead crane system that arrives in its own shipping container and can be assembled at an outdoor site in hours. It is the newest idea from global lifting leader Konecranes for safe, cost-effective lifting in remote areas where overhead lifting capabilities are needed.

[caption id="attachment_1003717817" align="alignleft" width="300"]

The record for setting up a CXT Explorer is 1 hour, 15 minutes.

The record for setting up a CXT Explorer is 1 hour, 15 minutes.[/caption]

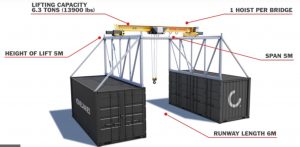

The CXT Explorer positions proven CXT electric overhead wire rope crane on top of a rugged steel structure supported by two standard ISO shipping containers. This concept, originally developed for vehicle maintenance in the military, brings the advantages of a factory crane to remote or temporary locations.

CXT Explorer is suitable for use in harsh conditions with temperatures ranging from –20 to +50°C. Outdoor features include rain covers, waterproof electrics, and heating in the motors and electrical cabinets to avoid condensation. The whole crane area can be covered with a special tent for additional protection if needed, and the unit can run on a generator if there is no source of electricity. The shipping containers that the crane rests on have a side door, and double as storage for crane components, service tools and spare parts. Best of all, it delivers factory-level lifting just a few hours after arriving on-site.

Konecranes CXT beats conventional mobile cranes in lifting capacity. It delivers true lifting capacity up to 5 tonnes in a relatively small footprint. A mobile crane would have to be rated at 15 tonnes to handle the same load. The simple operation of the CXT does not require a dedicated crane operation. And the CXT Explorer reduces operating costs compared to renting a mobile crane and skilled operators.

The CXT Explorer is finding a home in mills, refineries and factories performing onsite fabrication that requires precise control. Civil engineering projects like bridges and highway overpasses also benefit. The crane has a 5-metre lifting height and moves in six directions like a factory crane. Its lifting footprint is 6 metres along the rails and 5 metres between the containers.

Click

CXT Explorer to watch a set-up video. Each crane can be assembled in just a few hours, with Konecranes record time for setup being 1 hour and 15 minutes. When the crane is no longer needed, it can be packed back in its container and moved to the next job.

See also

www.Konecranes.com.

The record for setting up a CXT Explorer is 1 hour, 15 minutes.[/caption]

The CXT Explorer positions proven CXT electric overhead wire rope crane on top of a rugged steel structure supported by two standard ISO shipping containers. This concept, originally developed for vehicle maintenance in the military, brings the advantages of a factory crane to remote or temporary locations.

CXT Explorer is suitable for use in harsh conditions with temperatures ranging from –20 to +50°C. Outdoor features include rain covers, waterproof electrics, and heating in the motors and electrical cabinets to avoid condensation. The whole crane area can be covered with a special tent for additional protection if needed, and the unit can run on a generator if there is no source of electricity. The shipping containers that the crane rests on have a side door, and double as storage for crane components, service tools and spare parts. Best of all, it delivers factory-level lifting just a few hours after arriving on-site.

Konecranes CXT beats conventional mobile cranes in lifting capacity. It delivers true lifting capacity up to 5 tonnes in a relatively small footprint. A mobile crane would have to be rated at 15 tonnes to handle the same load. The simple operation of the CXT does not require a dedicated crane operation. And the CXT Explorer reduces operating costs compared to renting a mobile crane and skilled operators.

The CXT Explorer is finding a home in mills, refineries and factories performing onsite fabrication that requires precise control. Civil engineering projects like bridges and highway overpasses also benefit. The crane has a 5-metre lifting height and moves in six directions like a factory crane. Its lifting footprint is 6 metres along the rails and 5 metres between the containers.

Click

The record for setting up a CXT Explorer is 1 hour, 15 minutes.[/caption]

The CXT Explorer positions proven CXT electric overhead wire rope crane on top of a rugged steel structure supported by two standard ISO shipping containers. This concept, originally developed for vehicle maintenance in the military, brings the advantages of a factory crane to remote or temporary locations.

CXT Explorer is suitable for use in harsh conditions with temperatures ranging from –20 to +50°C. Outdoor features include rain covers, waterproof electrics, and heating in the motors and electrical cabinets to avoid condensation. The whole crane area can be covered with a special tent for additional protection if needed, and the unit can run on a generator if there is no source of electricity. The shipping containers that the crane rests on have a side door, and double as storage for crane components, service tools and spare parts. Best of all, it delivers factory-level lifting just a few hours after arriving on-site.

Konecranes CXT beats conventional mobile cranes in lifting capacity. It delivers true lifting capacity up to 5 tonnes in a relatively small footprint. A mobile crane would have to be rated at 15 tonnes to handle the same load. The simple operation of the CXT does not require a dedicated crane operation. And the CXT Explorer reduces operating costs compared to renting a mobile crane and skilled operators.

The CXT Explorer is finding a home in mills, refineries and factories performing onsite fabrication that requires precise control. Civil engineering projects like bridges and highway overpasses also benefit. The crane has a 5-metre lifting height and moves in six directions like a factory crane. Its lifting footprint is 6 metres along the rails and 5 metres between the containers.

Click

Comments