Cementation, Terra Nova complete Musselwhite ConRamp conveyor

Cementation Canada (CCI) and Terra Nova Technologies (TNT) have successfully completed their first joint project as a consolidated team for the Newmont ConRamp conveyor project located at Newmont’s Musselwhite mine, 500 km north of Thunder Bay in Ontario.

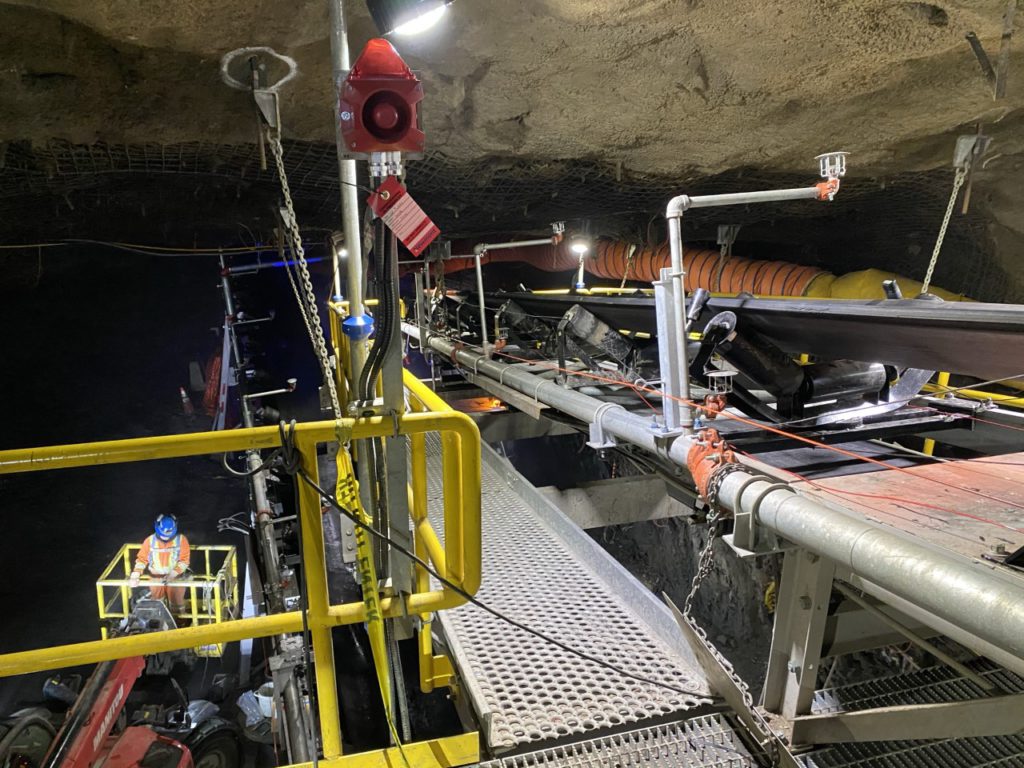

The project scope was to replace the main ConRamp conveyor system that was severely damaged in 2019. The main components of the system include two conveyors and a transfer tower and discharge chute. This was a general replacement ‘in kind’ along with requested safety and performance enhancements. The brownfield presented the usual challenges for engineering and construction.

CCI and TNT were responsible for the engineering, procurement and construction (EPC) for the entire project. The integrated EPC team allowed for seamless project delivery and reduced schedule time and cost. Newmont recognized this advantage and thus awarded the work to the CCI and TNT team.

The engineering involved the conveyor tables and associated components, main conveyor drives, conveyor pulleys, transfer tower between the two conveyors, prefabbed electrical room, gravity take up (GTU) units and overall system integration. Suppliers of the main components included DSI Dust Solutions, Sumiotomo, PPI Pulleys, Teco Motors and ABB.

As the design continued, a 3-D model was completed to show case the conveyor layout, which helped with the final design client approval. This layout provided a good visual for the construction crews to better understand the construction requirements.

Early in the construction, a 3-D Lidar scan was completed of the entire ConRamp to optimize the elevation of the conveyor tables and associated curvature of the system. This ensured that there was no interference between the wall and the conveyor tables during the final installation.

A monitoring system was also installed to monitor the temperature of the conveyor idlers and bearings. This is an early indication that bearings are comprised in the performance. This system consisted of four fibre optic cables along the length of the conveyor and strategically placed close to the bearings for quick sensing.

The construction was completed with an in-house workforce with sub-contractors for specialized tasks throughout the project. The project experienced the onset of the COVID-19 virus, which suspended site activities for over two months and reduced supply from many vendors and fabricators. The engineering and procurement work continued remotely and the plan for a return to site was developed with Newmont. Upon return to site, the work force availability was limited due to strict protocols instituted. This presented challenges with obtaining the large experienced work force required to complete the work.

The project started with a zero day float schedule as time was of the essence since the conveyor system is part of the main material handling system for the mine. Overall, the project was delivered safely with over 120,000 personnel hours without a lost time injury (LTI). Construction and commissioning were completed on schedule and integrated into Newmont’s full ramp up for returning back to full production.

Cementation Americas is a mining and minerals focused group of companies, delivering both underground and surface solutions for mines and downstream minerals processing facilities worldwide.

For more information, visit www.Cementation.com.

Comments