Capstone enters exploration deal with BHP Copper for project near Pinto Valley

Capstone Mining (TSX: CS) has entered into an 18-month agreement to conduct drilling and collect metallurgical samples at BHP Copper’s Copper Cities project, located 10 km east of Capstone’s Pinto Valley copper mine in Arizona.

Copper Cities was developed in the 1950s as part of the United States’ effort to increase copper output in support of the Korean War. The project including open pit mining, concentrate production and leaching. Milling ceased in 1989, and leaching continued until 1982. The U.S. Geological Survey estimates that the project hosts million 68.7 million tonnes of ore at a grade of 0.66% copper. Production totalled 895 lb. of copper, including 75 million lb. of copper cathode.

The Pinto Valley open pit mine, concentrator and solvent extraction/electrowinning (SX/EW) plant are located about 125 km east of Phoenix. Production began in 1975, and since that time the mine has produced more than 4 billion lb. of copper, including 500 million lb. of copper cathode. Capstone acquired the project from BHP Copper in 2013.

“We believe Copper Cities is geologically a mirror image of Pinto Valley with the same host rocks and age,” said Capstone senior VP of strategic project and exploration Brad Mercer. ”Our plan currently underway calls for a $6.7 million two phase drill program aimed at twinning historical drill holes and to select a portion of these for metallurgical testing.”

Capstone is currently studying how Pinto Valley production can be increased to increase cathode production to 300 million to 350 million lb. annually from mineralized waste over the two decades. Called PV4, the study includes the potential use of three technological innovations:

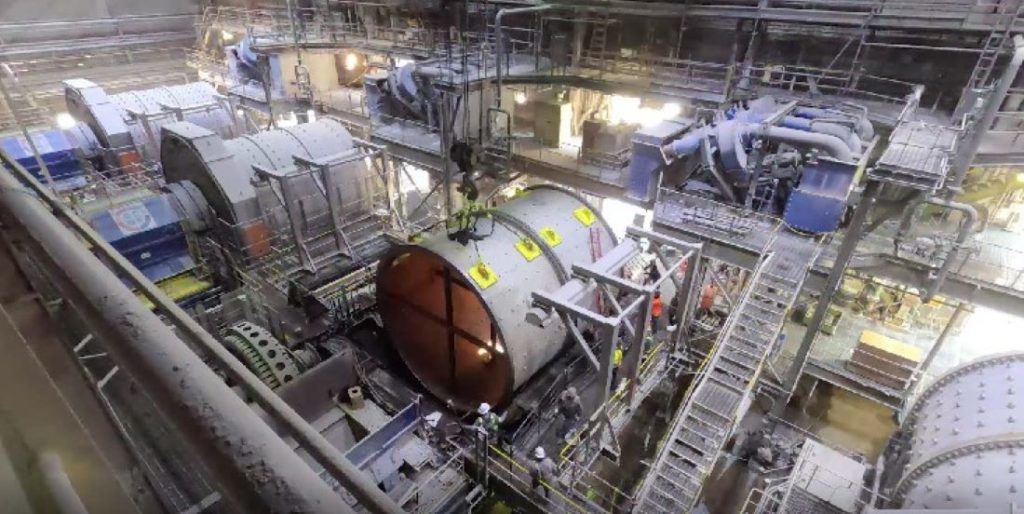

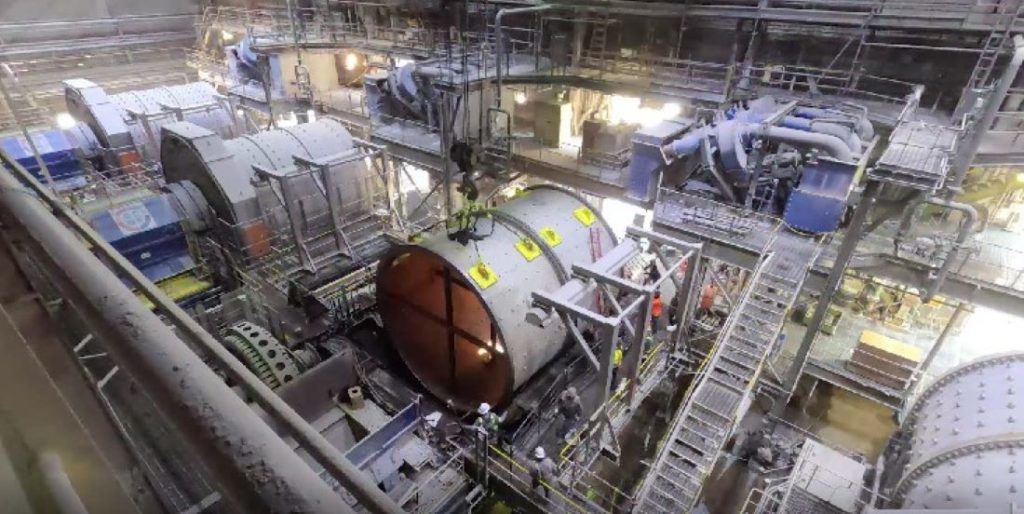

Last June, Capstone completed its SV3 mill optimization project, which included replacing the shell of ball mill #3. The project increased throughput and copper recovery while reducing water consumption by upgrading the tailings thickeners.

The Pinto Valley project has measured and indicated resources of 1.4 billion tonnes grading 0.29% copper (8.9 billion contained lb.) and 0.006% molybdenum (170 million contained pounds). The inferred resource is 170.6 million tonnes at 0.26% copper and 0.006% molybdenum.

Aside from Pinto Valley, Capstone operates the Cozamin copper-silver-mine in Mexico and is developing the Santo Domingo copper-iron-gold project in Chile. The company met its 2021 production guidelines with 85,000 tonnes of copper from Pinto Valley and Cozamin. This year guidelines have been set at 82,000 tonnes to 90,000 tonnes of copper including that provided by the Santo Domingo project. Capstone further said it plans to spend $192 million on capital projects and $14 million on exploration in 2022.

More information is posted on www.CapstoneMining.com.

Comments