Canada Nickel improves recovery and metallurgical performance at Crawford nickel project

Canada Nickel (TSXV: CNC; US-OTC: CNIKF) has released the results of testing done on samples from its 100%-owned flagship Crawford nickel-cobalt sulphide project in Ontario, about 40 km north of Timmins.

The company says that metallurgical improvements at the project will deliver increased recoveries of nickel, iron and cobalt, as well as enhanced magnetite concentrate quality. These are improvements from the preliminary economic assessment (PEA) for Crawford that was released in May.

The results stem from flowsheet optimization and come from a locked cycle test (LCT) that was conducted in late September. The LCT was the first to be completed since the Crawford PEA was released and was intended to measure the impact of flowsheet improvements made over the last four months. The sample selected for testing was a pentlandite dominant sample with a nickel head grade of 0.35%, an iron head grade of 6% and a sulphur to nickel ratio of 1:1.

Highlights included increasing the nickel recovery at the project, which is now set at 62%, a 19% improvement from the PEA. Iron recovery is 45%, a 5% increase from the PEA, while cobalt recovery is 70%, which is a 75% improvement from the PEA. Magnetite concentrate grades increase 14% to 54% iron.

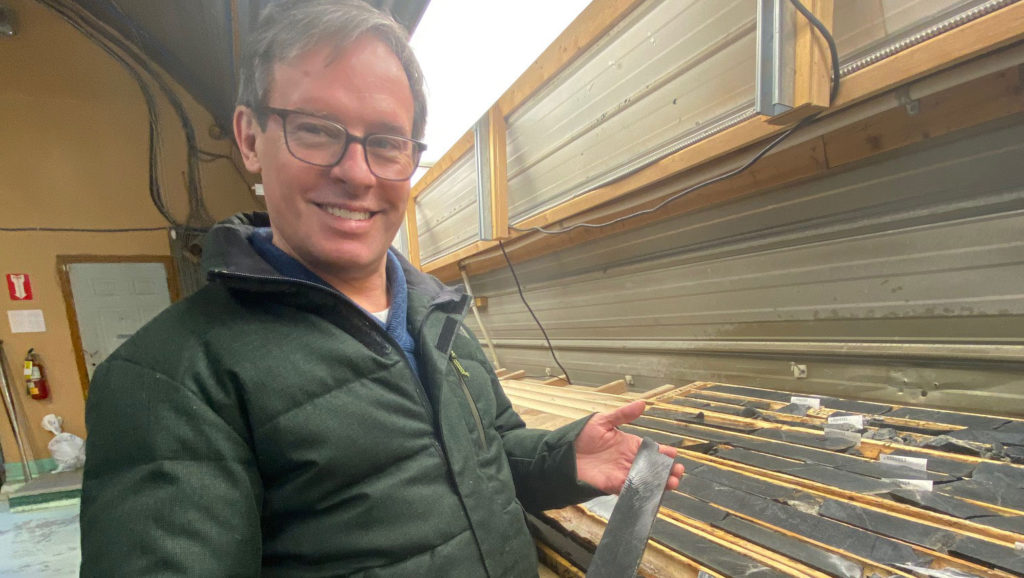

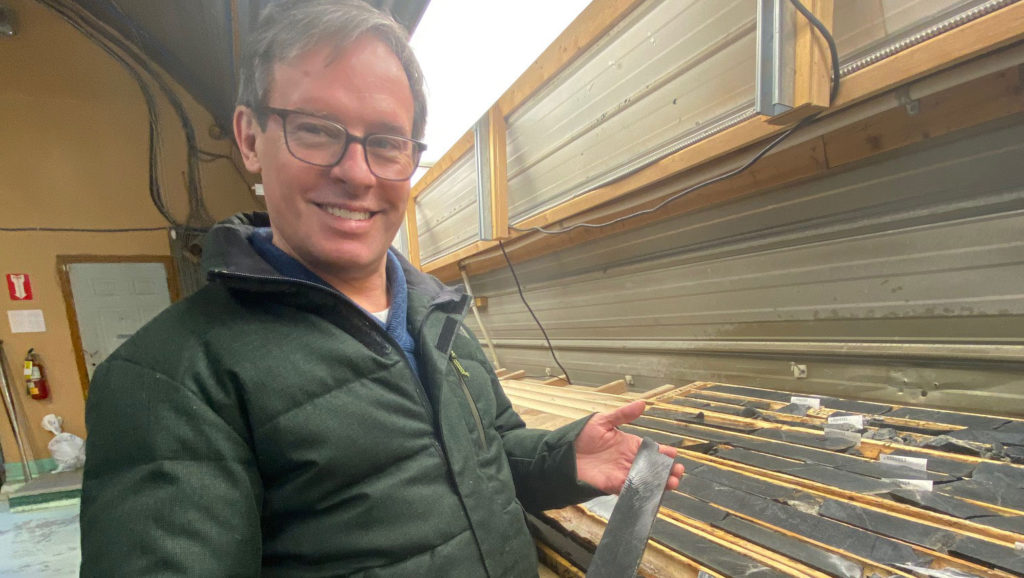

Canada Nickel’s chairman and CEO, Mark Selby, said the recovery improvements underscore the value of the deposit, and reinforce the company’s view that Crawford has the potential to become a new source of nickel and cobalt for the electric vehicle and stainless steel markets.

Comments