Canada Nickel announces improved Fe and Cr recoveries from piloting

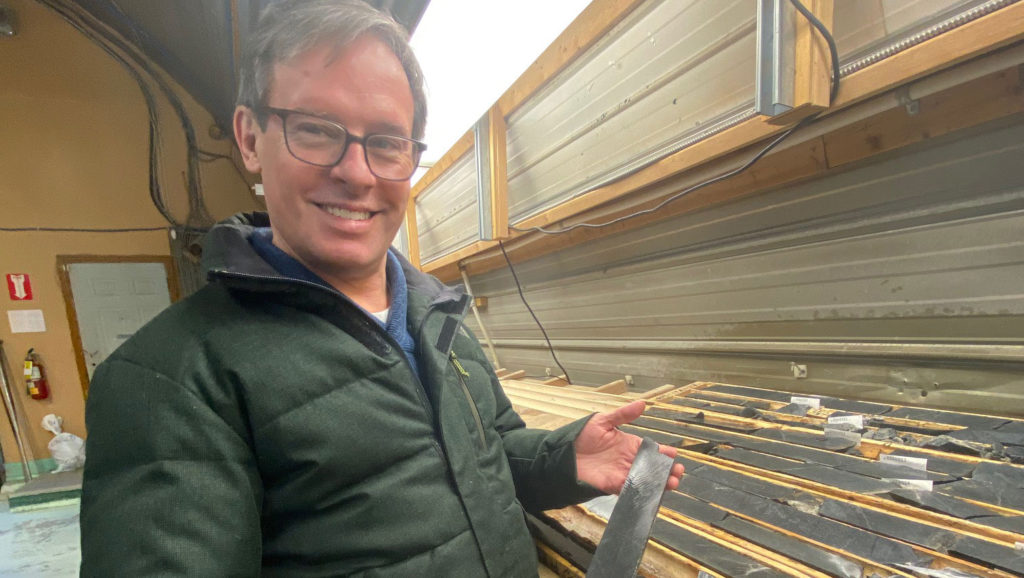

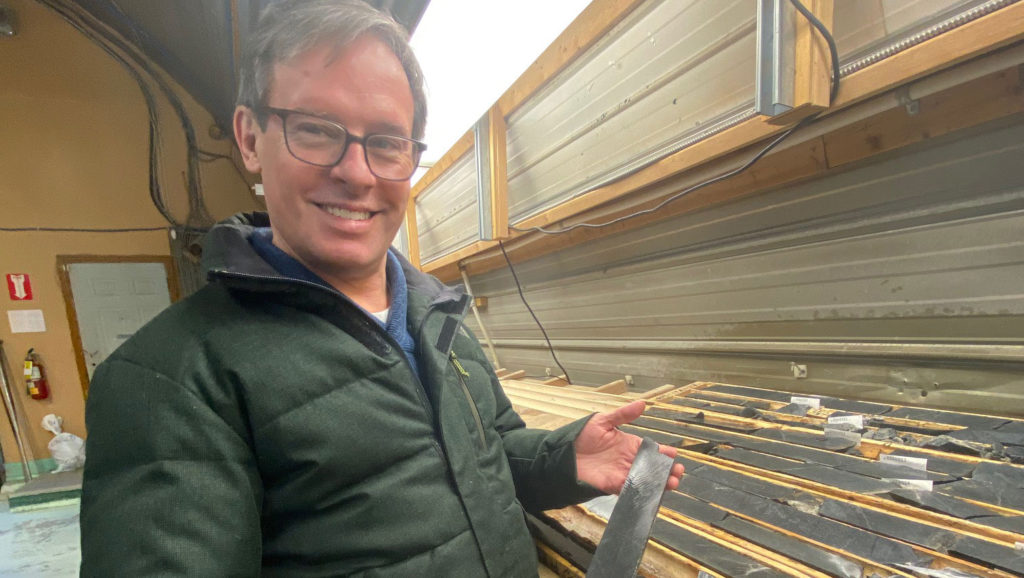

Canada Nickel (TSXV: CNC) announced the results from the initial phases of a pilot plant test, focused on testing an updated magnetite recovery circuit and generation of both nickel and magnetite concentrates, for more future testing. The tests were conducted on 34 tonnes of material from the company’s Crawford nickel project, which will primarily produce nickel, but output may also include by-products such as cobalt, palladium and platinum contained in nickel concentrates. Iron and chromium contained in the magnetite concentrate could also be produced at Crawford.

According to the company, the testing confirms significant improvements in both recovery and product quality from the updated magnetite circuit, including 8% improvement in iron recovery and 15% improvement in chromium recovery, and 16% improvement in iron grade to 55%.

Mark Selby, chair and CEO of Canada Nickel commented, "Our updated magnetite flowsheet has delivered outstanding improvements in both product quality and iron and chromium recoveries which we believe could add substantial additional value to the project. The pilot plant performance to date has exceeded our expectations in terms of operability and production and we look forward to the completion of the work on the final phase of nickel concentrate production."

For more information, visit www.canadanickel.com.

Comments