[caption id="attachment_1003729207" align="aligncenter" width="402"]

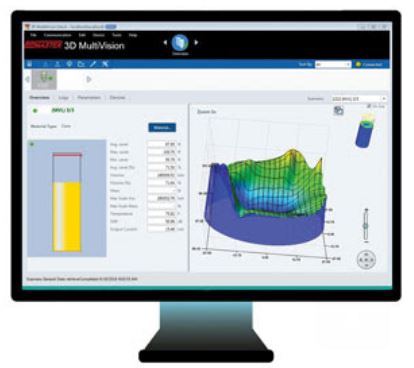

Information from BinMaster’s 3D level scanners makes monitoring inventory easy.

Information from BinMaster’s 3D level scanners makes monitoring inventory easy.[/caption]

NEBRASKA –

BinMaster suggests the use of its 3D level scanners to cure any of the following conditions:

- Uneven piles. If the material surface is irregular, a single measurement point in the silo is won’t render volumetric accuracy.

- Large diameter silos. Multiple measurements – combining multiple sensors – make volume accuracy far better in wide silos where levels can vary significantly.

- Safety stock headaches. Increase your ROI when you reduce the need for excessive safety stock and carrying costs.

- Inaccurate volume. If you’re constantly suffering from discrepancies, multiple measurements will yield higher accuracy by factoring in cone up or down conditions and sidewall buildup.

- Expensive materials. A few percentage points of inventory can represent tens of thousands of dollars.

- Mistaken inventory valuation. Inaccuracies in financial accounting can lead to write-offs and maybe even the difference between profit and loss.

- Multiple filling or discharge points. This can cause surface irregularities and in severe cases, cause structural stress on the vessel.

- Dusty conditions. Acoustic pulses are immune to dust ensuring measurements are reliable.

- Visual impairment. A 3D image provides visual confirmation of material behavior – something available only from a 3DLevelScanner.

- Not enough storage capacity. Operations can optimize storage capacity and minimize ground storage.

3D MultiVision software uses signals from 3DLevelScanners to map content topography. Images and detailed results are provided for each silo, making it easy to monitor inventory.

Over 10 years, BinMaster has installed more than 3,000 3DLevelScanners in some of the largest silos, toughest applications, as well as in difficult materials like cement, alumina, DDGS, soymeal, salt, flour, and frac sand.

Let BinMaster help you cure your inventory ailments. Visit

www. BinMaster.com or give them a call at 800-278-4241.

Information from BinMaster’s 3D level scanners makes monitoring inventory easy.[/caption]

NEBRASKA – BinMaster suggests the use of its 3D level scanners to cure any of the following conditions:

Information from BinMaster’s 3D level scanners makes monitoring inventory easy.[/caption]

NEBRASKA – BinMaster suggests the use of its 3D level scanners to cure any of the following conditions:

Comments