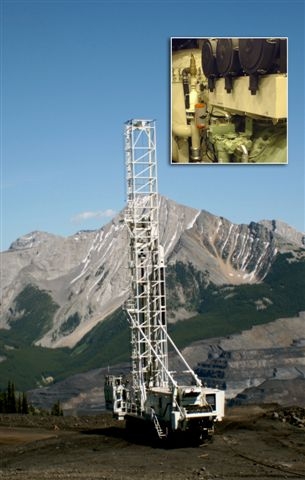

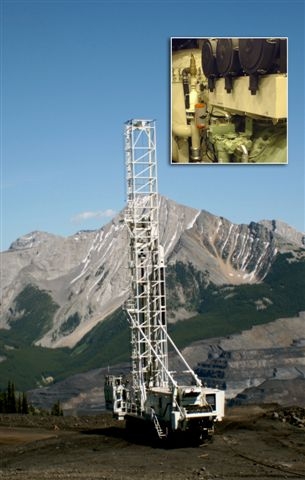

BLASTHOLE DRILLING: Bucyrus 49HR rig equipped for high altitude efficiency

SOUTH MILWAUKEE, Wisconsin — From Bucyrus International comes news that one of its 49HR rotary blasthole drills equipped with a high-altitude compressor option has been commissioned at the Collahuasi copper mine in Chile. It is the first of two such drills to be equipped with 107-m3/min air compressors and delivered this year.

The Collahuasi mine (Xstrata Copper 44%, Anglo American 44% and a Japanese consortium 12%) is situated in northern Chile, at an elevation of 4,500 meters. The combination of the 49HR drill and air compressor will maximize drill productivity by enabling drill operators to achieve target bailing velocity and optimum radial clearance. Other compressors de-rate in high-elevation and high-temperature environments, causing bailing velocity to decrease. As bailing velocity deteriorates, so too will drill productivity.

In addition to the productivity benefits offered, the Bucyrus 49HR drill equipped with a 107-m3/min air compressor offers energy savings. Because the this compressor uses an operating pressure of 448 kPa, as opposed to 758.4 kPa, the drill operate at lower horsepower, as much as 200 hp less, according to Bucyrus.

Bucyrus drills equipped with 107-m3/min air compressors also offer advantages in mines with fractured rock strata, as air released from the compressor can escape into ground cracks, causing loss of air volume. The added power offered the high-altitude compressor will reduce the net loss of air volume in porous ground.

For more information on Bucyrus drilling solutions, visit www.Bucyrus.com/drills.htm.

Comments