Almonty advances Sangdong tungsten mine in South Korea

Almonty Industries (TSX: AII; OTC: ALMTF; ASX: AII) says June and July were particularly busy at its tungsten mine development project in South Korea. The Metso protection screen and reclaim feeders arrived. This followed the arrive of the semi-autogenous grinding (SAG) mill and ball mill.

Delivery of the grizzly screens and UFS screens from France and Brazil will be next, followed by the shipping of the apron feeder from Turkey.

Engineering and civil works are also advancing. Detailed plans for the crusher are and stockpile were completed. Drawings for the grinding and classification sections will be the next to be finalized.

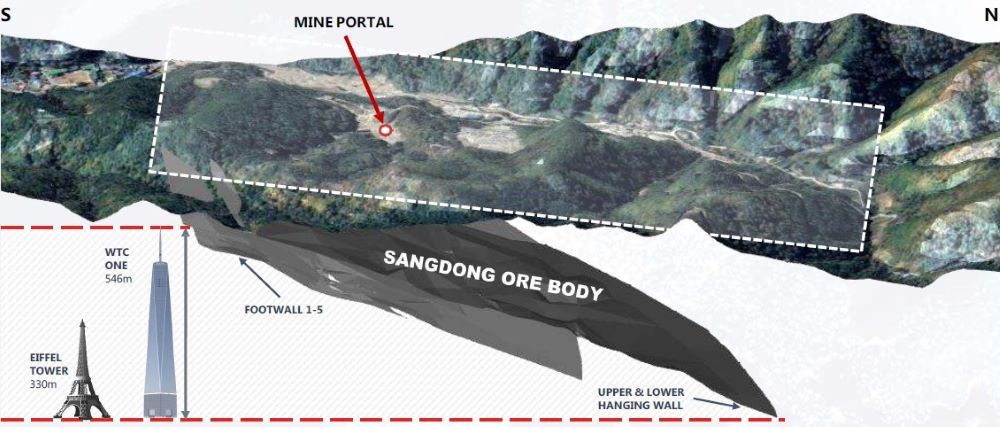

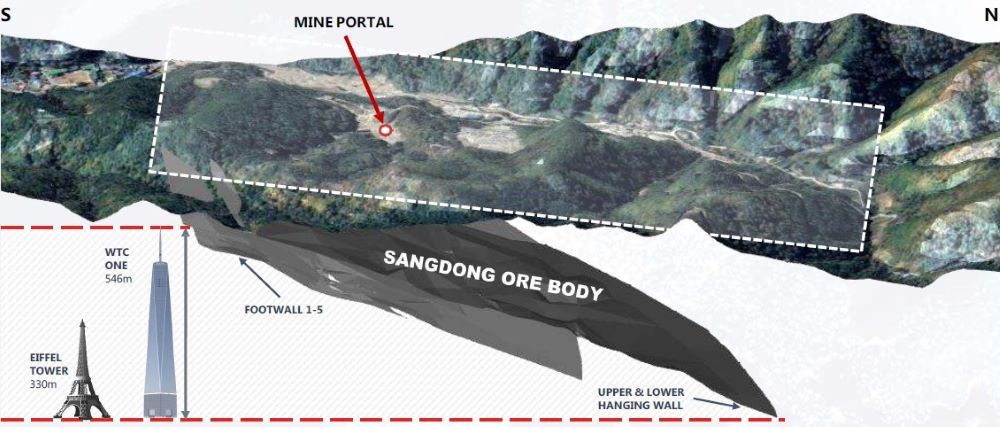

The Sangdong mine was historically one of the largest tungsten mines in the world and one of the few long-life, high-grade tungsten deposits outside China. Almonty acquired it in 2015 when its bought 100% in former owner Woulfe Mining. The fully permitted mine has a potential life of 90 years and is being reopened at a cost of only US$75 million. Project commissioning will be complete by the end of 2024, followed by a 12-month ramp-up period. The first phase of production will average 2.3 million tonnes of tungsten oxide (WO3) annually. The second phase expansion will boost that to 4.8 million t/y. The second phase also includes a tungsten oxide plant.

The Sangdong deposits contains an estimated proven and probable reserve of 7.9 million tonnes grading 0.45% WO3. The measured and indicated resources, including reserves, are 8.3 million tonnes at 0.49% WO3, and the inferred resource is 52.8 million tonnes at 0.44% WO3.

Further details about Almonty Korea Tungsten, a subsidiary of Almonty, can be found at www.Almonty.com.

Comments