Rajant tackles mining’s big communications challenges

When Rajant sold its first wireless communications equipment in the mining sector in 2005, it was to Rio Tinto’s Bingham copper mine, in Utah.

As Todd Rigby, Rajant’s director of sales notes, the open-pit mine is both very large and very complex. The communications system at the time was a patchwork of different networks that were specific to individual applications, such as fleet management and fuel monitoring.

“They had a number of different networks, each supporting individual apps and these essentially consumed all the available non-licenced frequency and channels,” Rigby explains.

“They came to the conclusion that they needed to find a high-performance network that used spectrum more efficiently and had the ability to carry more bandwidth so they could transfer their existing applications onto that network and have sufficient excess capacity to add additional apps down the road.”

More than a decade later, Rajant is seeing the same situation occur in underground mines.

“We’re getting calls literally on a weekly basis from underground mines that have several different types of communications systems running different apps and they’re up against the wall with the capacity of those systems,” Rigby says.

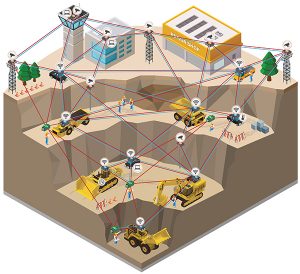

Rajant can offer those underground operations higher capacity with its private broadband mobile network. The company’s proprietary Kinetic Mesh technology, offers reliabile connectivity via a network of wireless nodes, which Rajant calls “Bread- Crumbs,” and which offer redundant connectivity to ensure signals don’t drop.

“Connectivity is really an area where Rajant shines brightly and it ties back into our proprietary networking protocol that allows each node to maintain multiple redundant active and persistent connections to other devices,” Rigby says. “What that translates to is in a Rajant network, we can maintain continuous even connectivity as the network moves.”

Underground coverage is more expensive than above ground because it’s a line of sight network.

“A device needs to see another device to communicate with it,” Rigby notes. “It’s safe to say you’re going to need them closer underground than you do above ground to form a reliable network.”

However, reliable connectivity is required for automation, and has huge payoffs in safety.

With the combination of a reliable wireless network and machine sensors and apps, mining operations can ensure that machine health systems, proximity apps, and asset tracking tools are always on, and equipment can be automatically shut down when threats arise.

Rajant’s military grade technology also offers a high degree of security.

“While we are proprietary, we do support industry standards,” Rigby adds. “So you can activiate our devices to also act as a Wi-Fi access point and we support all the access point security up to AES 256-bit encryption.”

Comments