Using a regeneration lens: waste becomes a resource (part 2)

Regeneration is an energy transition start-up that produces biodiversity, community, and climate positive minerals for the energy transition, green technology, and sustainable brands through re-mining, reprocessing, and restoration.

If the primary targets are legacy and historic mine and mill sites, there should be an emphasis on critical mineral production and the utilization of these sites for biodiversity restoration, renewable energy production, and carbon sequestration. Here, we explore the interdependence of site strategies, technologies, and policy innovation that contribute to our approach. We believe these have industry-wide relevance.

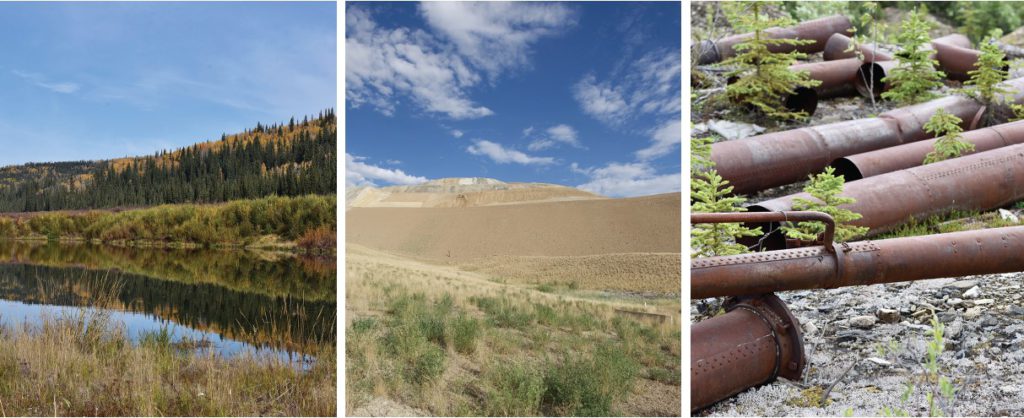

Legacy and historic mine sites, and mine and milling waste, can become environmental and community assets.

Start with a new vision for legacy mine sites

A nature positive development company would have two main functions: re-mining and restoration. Tailings, milling and processing residues, waste rock, and mine impacted waters represent opportunities to recover metals and minerals as well as create new products. With this in mind, people should take a fresh look at mining and milling waste.

A key objective is to finance restoration with revenue from minerals and, where possible, both renewable and nature-based products and outcomes. This is a different approach from the purely commercial re-mining and reprocessing of mine and milling wastes.

Achieving that objective requires assembling a portfolio of sites with the potential to create lasting value for communities and partners. For each site, work to create a coalition with a shared closure vision.

Characterizing the waste and identifying its potential value is one critical element.

An intensive focus on technology helps us unlock residual value. Always seek the best recovery technologies (existing or new) that fit the challenges of the site and are scalable to a production rate not necessarily defined by traditional economic metrics.

Envision, design, and implement a clear path to a rehabilitated site that meets the needs of communities and governments.

Site assessment lens filters for net positive outcomes include the following:

- Improved post-mining environmental outcomes that effectively reduce site liabilities.

- Community support for and benefits from post-mining land use.

- Production of strategically important critical metals and minerals.

- Meeting the needs of downstream partners to source responsible metals and minerals.

For each site, the case presented to an investment committee should be unique and may include metal production, new products from waste, and other revenue streams aligned with our public benefit goals including value from biodiversity and carbon credits, environmental and closure services fees, and liability reduction. Depending on the site, maximize value through the inclusion of renewable energy production, carbon sequestration, water management, agriculture, and other economic opportunities.

Good methodology, informed by site-based learning, can be a catalyst for reducing the inventory of abandoned and legacy mine sites.

No longer will legacy sites suffer from minimum levels of compliance, nor will these sites simply be ‘managed.’

Legacy sites as technology incubators

There is a market gap. A rush of new technologies need access to mine sites for ground-truthing and testing. There are also proven technologies that can be re-applied to waste. However, access to sites is difficult.

The mining sector is not kind to innovation, where a “willing to test, fail, and try again” mentality is essential.

It is challenging for mining majors to support small scale trials, and potential liability issues can be prohibitive, creating an obstacle for technology innovators.

Mining juniors are trying to develop specific projects. Utilizing new, unproven technologies can lead to investor skepticism.

Proponents of new technologies can be viewed skeptically as trying to pitch one technology or system, even where an alternative may be better suited.

In fact, a focus on just one technology would narrow both market and impact because different sites require varied technology solutions. This can be solved by partnering with a range of technology providers, matching the right innovations with the right problems.

The use of proven and emerging technologies does not prevent the application of new technologies throughout the mineral extraction value chain, including those for waste characterization, material handling, processing and recovery, products, waste management, reclamation, water treatment, and CO2 management.

Technology developers should have access to mining and milling sites to trial, verify, and validate their technologies.

For example, as a technology ecosystem partner, we are currently testing the application of an emerging technology, partnering with its developer to reduce the volume of bauxite residues.

An enabling policy environment

Working within the current regulatory context and seeking policy innovations will accelerate improved community and environmental outcomes while producing minerals for the energy transition. Policy, regulation, and voluntary standards can be modernized to support these goals.

Full value mining, optimizing the efficiency of extraction and production, at legacy, historic, and operating mine and mill sites should be incentivized.

Policies that support the use of proceeds from re-mining to restore and close abandoned mine sites are in the public interest. The community is better off and restored sites support the biodiversity goals of numerous governments.

Because these sites can produce carbon and biodiversity benefits, support for accessible credit and offset markets, including the development and use of transparent, credible tools to support these transactions, is essential. Tools and transparent markets will bring value for Indigenous governments and communities.

Communities can benefit from responsible sourcing and procurement standards that go beyond de-risking supply chains by rewarding minerals produced from re-mining and reprocessing, especially where restoration takes place. Through partnerships, new standards for restoration, re-mining, and Indigenous participation can be developed and tested.

To ignite a start-up culture and smart risk-taking, legacy sites can be treated as innovation and technology laboratories with tax incentives, grants, and funding for local and business partnerships. Some sites can be supported to test re-mining methods, develop biodiversity credits, and deploy renewables and green energy infrastructure.

This approach can support development efforts in countries with mineral resources. Sharing these strategies and tools with support from development agencies can strengthen and support development goals and enhance critical minerals supply chains.

Where governments are considering procurement policies and incentives that support the circular economy, definitions should include pre-consumer circularity, like products from metals extracted from mine waste.

Achieving an impact

This model requires us to build on mining’s traditions (the love of exploration, the value of discovery, and a hyper-focus on safety), ignite a start-up culture and thirst for innovation, and empower our restoration visionaries, whether in the profession or communities.

David Baker is the chief operating officer, Regeneration. Stephen D’Esposito is the founder and CEO, Regeneration. He is also the president of Resolve. John Thompson is the chief innovation officer, Regeneration.

Comments