The importance of underground ventilation

Mine ventilation monitoring and controls to reduce greenhouse gas emissions

Underground mining is a critical industry that provides essential minerals and resources for various sectors including the new green economy. However, it also poses significant environmental and health challenges, particularly in terms of greenhouse gas (GHG) emissions and air quality for the underground miners.

Ventilation in underground mines serves multiple purposes. It ensures a supply of fresh air to miners, dilutes and removes hazardous gases, and controls the temperature and humidity levels within the mine. Without proper ventilation, miners are exposed to dangerous levels of toxic gases such as carbon monoxide (CO), nitrogen oxides (NOx), dust, and diesel particulate matter (DPM), which can lead to severe health issues and even fatalities.

Moreover, without directing the air to the correct location, the ventilation circuit will result in increased GHG emissions. Mines often rely on diesel-powered equipment, which emits significant amounts of CO and NO2 pollutants. Effective ventilation systems help to disperse these emissions, reducing their concentration and impact on human health.

Traditional ventilation systems in mines are often based on fixed schedules and manual adjustments via drop board manual regulators, which are inefficient and fail to respond to real-time changes in the mine environment. This is where advanced monitoring and control systems come into play. By continuously monitoring air quality and adjusting ventilation parameters in real-time, these systems can optimize air flow, reduce energy consumption, and minimize GHG emissions by as much as 50%.

The Vigilante AQS Air Quality Station by Maestro Digital Mine is a state-of-the-art solution designed to provide real-time monitoring of air quality in underground mines. It measures various parameters, including airflow rate, CO, NOx, dust, temperature, and humidity, providing comprehensive data on the mine’s atmospheric conditions.

One of the key features of the Vigilante AQS is its ability to integrate with existing mine ventilation systems. This integration allows for automated adjustments based on real-time data, ensuring optimal air quality and energy efficiency. For instance, if the system detects high levels of CO or low levels of airflow, it can increase ventilation to dilute these contaminants, thereby protecting miners’ health while minimizing the mine’s overall GHG emissions. By directing ventilation to areas where it is most needed, mines can ensure that air quality is maintained without over-ventilating areas with fewer people and equipment.

Complementing the Vigilante AQS, MaestroFlex regulators are designed to control the flow of air within the mine’s ventilation network. These regulators can be adjusted remotely, allowing for precise control over ventilation rates in different zones of the mine. This flexibility is crucial for responding to dynamic changes in the mine environment, such as varying levels of gas emissions, changes in temperature, or modification of mobile equipment.

By using MaestroFlex regulators in conjunction with the Vigilante AQS, mines can achieve a highly responsive and efficient ventilation system without the necessity of expensive PLC or DCS panels. This combination not only enhances the safety and comfort of miners but also contributes to significant reductions in energy consumption and GHG emissions while reducing project capital expenses.

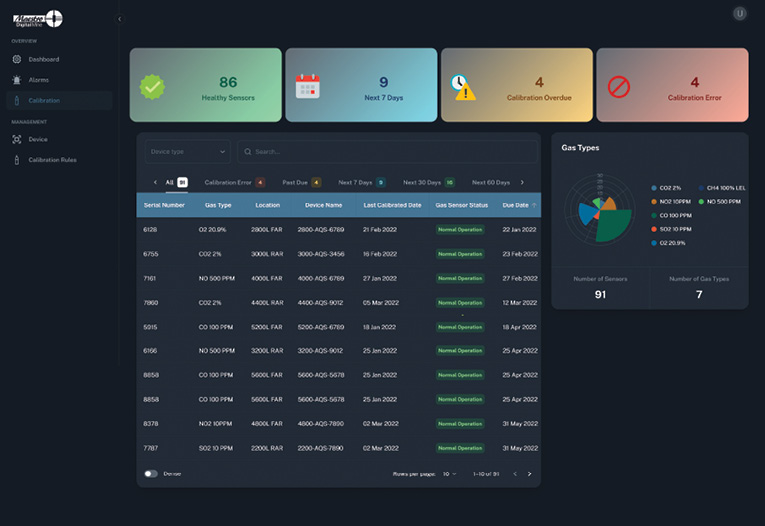

Duetto Analytics, an on-premises software platform, provides advanced diagnostics to ensure the reliability and safety of the ventilation industrial internet of things (IIoT) devices by providing real-time monitoring and fault detection. This allows for the early identification of potential issues, preventing minor problems from escalating into major failures.

One of the significant benefits of advanced diagnostics is enabling predictive maintenance. By analyzing data from IIoT devices, this software can predict when equipment is likely to fail and schedule maintenance before a breakdown occurs. This not only reduces downtime but also extends the lifespan of the devices.

Ventilation on demand (VOD) systems rely heavily on sensors to monitor air quality and the sensors require frequent maintenance to maintain accuracy to enable the system’s effectiveness. Duetto Analytics solves the “Achilles heel” of VOD systems by tracking and recording sensor calibrations both for regulatory and system reliability.

Lowering GHG, boosting efficiency

One of the primary environmental benefits of advanced ventilation monitoring and control systems is the reduction of GHG emissions. By optimizing ventilation rates and ensuring that air quality is maintained at safe levels, these systems can significantly reduce the amount of energy required for ventilation. This, in turn, leads to lower CO2 emissions from the mine’s power sources. This is particularly important in the context of global efforts to combat climate change and reduce industrial GHG emissions.

Beyond environmental benefits, advanced ventilation systems also offer significant operational advantages. Real-time monitoring and control allow for improving the overall productivity of mining operations by assuring the miners return to the face quicker and safer.

Furthermore, the ability to remotely adjust ventilation parameters reduces the need for manual interventions, freeing up personnel to focus on other critical tasks. This not only enhances operational efficiency but also improves safety by reducing the exposure of workers to hazardous conditions.

Case studies and real-world applications

With installations in over 40 countries, mines around the world have successfully implemented Maestro Digital Mine’s Vigilante AQS and MaestroFlex regulators, demonstrating the practical benefits of these technologies. For instance, several mines in Canada reported a significant reduction in energy consumption and GHG emissions after integrating these systems into their ventilation network. The real-time data provided by the Vigilante AQS allowed the mine to make informed decisions about ventilation adjustments, leading to improved air quality and reduced environmental impact.

Similarly, a mining operation in Australia achieved enhanced operational efficiency and worker safety by using MaestroFlex regulators to control air flow in response to real-time conditions. The ability to remotely adjust ventilation rates allowed the mine to quickly respond to changes in gas concentrations and temperature, ensuring a safe and comfortable working environment for miners.

Conclusion

The importance of underground mine ventilation monitoring and controls cannot be overstated. Effective ventilation systems are essential for maintaining safe working conditions, protecting miners’ health, and reducing the energy intensity of mining operations. Maestro Digital Mine’s Vigilante AQS air quality stations and MaestroFlex automated regulators represent cutting-edge solutions that enable mines to achieve these goals through real-time monitoring and control.

By integrating these advanced technologies into their ventilation systems, mines can significantly reduce GHG emissions, enhance operational efficiency, and ensure a safer working environment for their personnel. As the mining industry continues to evolve, the adoption of innovative ventilation solutions will play a crucial role in promoting sustainability and reducing the environmental footprint of mining activities.

By Maestro staff writer

Comments