Costmine: The effect of rock’s compressive strength on costs

The mining industry operates in a dynamic and challenging environment where various factors influence the overall cost of mining operations. Efficiently managing these parameters is crucial for optimizing productivity and ensuring profitability. While many aspects have been extensively studied and incorporated into mining strategies, certain key factors, such as compressive strength, have often been overlooked or not given sufficient attention. This article aims to shed light on the significance of compressive strength as one of the major factors of mining costs.

Mining operations involve a multitude of parameters that directly or indirectly impact the cost of extraction, processing, and transportation. Parameters like ore grade, deposit depth, and mineralogy have long been recognized as critical factors affecting mining costs. Other parameters, such as labour costs, energy consumption, and environmental regulations, have also received considerable attention in the mining industry. Companies invest significant resources in analyzing and optimizing these factors to minimize costs and maximize operational efficiency. However, the influence of compressive strength on mining costs has often been underestimated, despite its crucial role in determining the feasibility and profitability of mining operations.

Compressive strength, referring to the ability of a rock or ore body to resist compression or breakage, is an essential geological property that directly influences the choice of mining methods, equipment selection, fragmentation, and overall operational planning. This article targets the effects of compressive strength on open-pit gold heap leach mining operations. A set of five identical models with different compressive strength values, ranging from 80,000 kPa to 240,000 kPa with a 40,000 kPa increment, were created using cloud-based SHERPA Surface software powered by Costmine. It is worth mentioning that all other parameters, such as labour costs, equipment costs, and supply costs, were provided by other Costmine publications, including Mining and Mill Equipment Costs Guide and Mining Cost Service. These established sources ensure the reliability and accuracy of the cost-related information incorporated in the analysis. For further information, please visit the Costmine website at costmine.com.

This article addresses the impact of compressive strength on blasting supply, equipment, hourly personnel requirement operating costs, and capital costs in a specific mining operation scenario. The study assumes a mine life of 14 years, comprising a two-year pre-production period with 3,500,000 tonnes of stripping and four three-year phases, each averaging 40,000 ore t/d. The total minable resources are estimated at 168 million tonnes, and the mine operates on a schedule of two 12-hour shifts per day for 350 days per year. The rock quality designation (RQD) is assumed to be 82% and has a 2.60 t/m3 density.

Blasting supply

By increasing the compressive strength of rock, the powder factor, which represents the weight of explosive required to fragment a specific amount of rock, also rises. Consequently, the amount of explosive agent needed increases accordingly. Moreover, as compressive strength influences the drill hole pattern, it becomes necessary to increase the number of drill holes leading to a greater requirement for cap, primers, and detonation cord.

The correlation between compressive strength and bit wear is a crucial aspect to consider in drilling operations as well. As the compressive strength of the rock increases, it tends to have a direct impact on the wear and tear experienced by the drilling bits. Higher compressive strength leads to increased resistance and hardness of the rock, which can result in accelerated bit wear.

Equipment

Compressive strength exerts a profound impact on rock drilling, playing a pivotal role in determining the efficiency and effectiveness of drilling operations. As the compressive strength of the rock increases, the drilling process becomes more arduous and challenging. Depending on the scale of the operation, it necessitates a higher utilization of drill equipment and may even require additional drills.

Moreover, as discussed in the previous section on blasting supply, the heightened compressive strength demands an increased amount of explosive agent. This, in turn, prompts a need to either augment the utilization of bulk trucks or increase their numbers. It is worth noting that escalation in equipment utilization or the addition of more equipment directly correlates with an increase in fuel consumption.

Hourly personnel requirements

In the equipment section, it was observed that the number of equipment or their utilization rises with increasing compressive strength. Consequently, this leads to heightened demand for drillers, mechanics, and labour responsible for operating the drills, maintaining the equipment, and operating the bulk trucks, respectively.

Operating and capital cost

The operating costs in mining operations encompass various components that contribute to the overall financial expenditure. Figure 1 outlines the operating costs associated with supplies, hourly labour, equipment operation, salaried labour, and miscellaneous expenses. As depicted in Figure 1, these costs tend to increase with higher compressive strength, indicating the impact of rock properties on operational expenses. Notably, the total operating costs exhibit an upward trend as compressive strength rises.

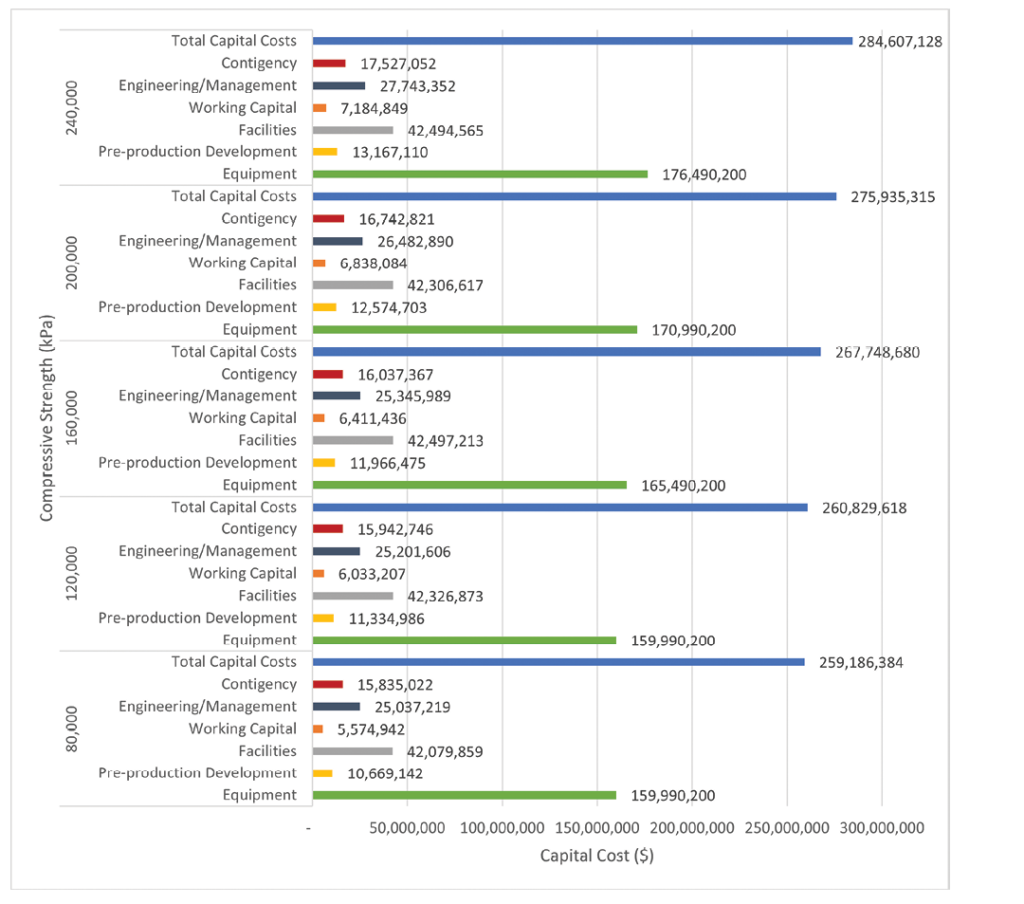

Capital costs are a vital consideration in mining ventures, covering a range of expenditures, such as equipment, pre-production development, facilities, working capital, engineering/management, and contingency, which is 10% of the summation of all the parameters. Figure 2 visually represents the capital costs associated with various compressive strength scenarios, showcasing the financial investment required for mining operations. Notably, the figure reveals a clear trend indicating that as the compressive strength increases, so does the total capital cost. This correlation emphasizes the impact of rock properties on the financial aspects of mining projects, highlighting the need for careful budgeting and resource allocation. CMJ

Ali Vossoughian is a mining engineer with Costmine.

Comments