Ten best practices for mine water treatment

Canada’s mining industry is held to some of the world’s highest standards when it comes to protecting the environment. As a result, there is an ever-evolving desire to improve and implement best practices. Mine water treatment is a complex subject and selecting water treatment approaches requires consideration of many aspects. However, there are several current best practices that should be applied to all projects. Some of these have been used for decades, while others are emerging and aspirational. With decades of experience in mine water treatment and hundreds of discussions with proponents, consultants, regulators, and stakeholders, we have created a list of best practices that will be useful for everyone in the mining sector, regardless of your role.

1. Keep clean water clean, prevent contamination

While this may seem like common sense, it can be difficult to implement. Well known applications include diversion structures and contouring. It can also take the form of implementing covers and revegetation progressively during operations. The aspect of “prevent rather than treat” is a more recent addition to this best practice and involves application of in situ (in place) source control measures. Examples of well-known applications of this principal include adding pH buffering materials (such as lime) and using water covers to prevent oxygen from reaching tailings or waste rock and maintain neutral conditions. A more modern example is to implement redox buffering, using biological processes and biogeochemical interactions to buffer oxidation in pit lakes, tailings ponds, and underground mine pools. While these applications can also help to treat contaminated water, their application can also maintain conditions that prevent the contamination of water.

2. Use a site-specific approach

Gone are the days of out of the box ‘cookie-cutter’ type water treatment systems. We now know that each mine is totally unique in its water quality and needs, and therefore requires a customized and site-specific approach to water treatment. While traditional turnkey water treatment systems still have a role in the overall water treatment and water management strategy, it is now recognized that they work best as part of a bigger strategy. Some other considerations of a site-specific approach include:

> End use of water

> Water chemistry and constituents targeted for treatment

> Lifespan of treatment system

> Lead time for system operation

> Constructable land area

> Climate

> Periodicity of treatment

> Site infrastructure that can be repurposed (e.g., pit lakes, mine pools, tailings ponds)

> Availability of local materials

3. Appreciate that water treatment changes with the mine life cycle

Water quality and volumes will change over the lifespan of a mine. Fortunately, many of these changes are predictable and can be planned for. For example, in the construction and early closure stages when earth moving activities are extensive, higher turbidity and suspended solids are expected. During active blasting, there is an increase in nitrogen species such as ammonia, nitrate and nitrite, which eventually converts into nitrate, that finally deplete into closure. In contrast, metals and metalloids can increase over time through oxidation. The source and location of water also changes throughout the life of a mine (e.g., dewatering, milling, and metallurgical processes) which creates contact water during operations. These considerations must be incorporated into the water treatment plan.

4. Respect the fate, form, distribution, and stability of treated constituents

The focus of water treatment has historically been on removing contaminants from the water; however, this often results in secondary waste streams. Many active treatment systems create byproducts such as sludges and brines which must be considered in the long-term viability of the site-wide water management strategy. For example, if a sludge or brine is being placed into an area where water is stored, this must be considered for future water treatment plans. If more modern semi-passive or in situ treatment system is used, the stability of the entrained constituents and minerals must be considered.

5. Design with closure in mind and use passive or semi-passive treatment

When developing a new asset or updating an existing one, the water management and treatment strategy should take a primary role in the process of developing the site layout. A newer inclusion in this planning and best practices is an increasing number of jurisdictions requesting or requiring that passive or semi-passive treatment be used for closure. In many places, active treatment in perpetuity is now regarded as impractical for either implementation or bonding. Therefore, passive and semi-passive treatment methods are being sought to increase the sustainability of treatment and decrease the long-term costs of mine closure. To achieve this, the proposed mine plan should be developed with this in mind. This places long-term water treatment and closure plans at the table alongside with asset development plans to assess overall project return on investment.

6. Decentralize treatment, treat as close to the source as possible

Treating water at the source reduces environmental exposure and potential risks of further contamination. Older approaches to mine water treatment gathered all water from a site together in one place for treatment. Modern approaches consider the chemistry of the water and how mixing different sources will impact the overall treatability. This can significantly decrease water treatment operating costs and often creates more stable byproducts. This can also allow for more water to be reused on site, decreasing overall consumption. However, the cost of multiple treatment systems can be high. To offset this, semi-passive and in situ treatment is often used at source points to achieve the same outcomes without the excess capital. Where permits require single discharge points, water can be combined post treatment for discharge.

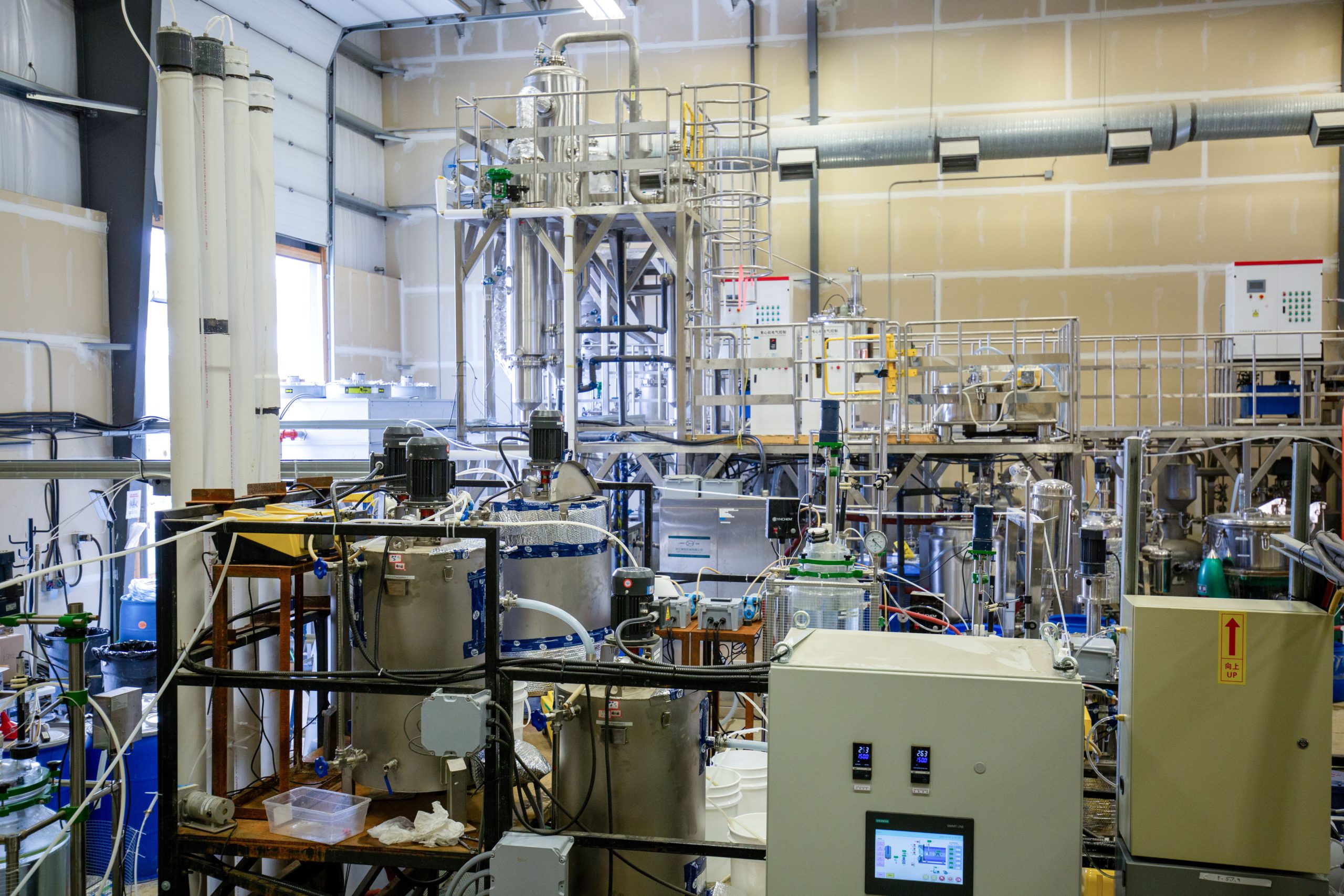

7. Integrate technologies with treatment trains for best outcomes

The overall chemistry of the water will impact how effectively the water can be treated. A ‘treatment train’ most often refers to a system with stepwise treatment designed to ensure potential inhibiting compounds are removed. For example, filtration is a step before reverse osmosis. Treatment trains can also be used to decrease overall operating costs. This often involves using semi-passive treatment in some steps. However, not all technologies are compatible, so this must be approached with an integrated plan.

8. Use a team of experts

Water treatment technology is advancing as quickly as the other technologies in your life. Where large multidisciplinary firms used to be a go-to for water treatment consulting, there is a trend towards using smaller, nimbler, specialist firms who stay at the leading edge of their specific technology area. This emergence of more niche firms requires skilled integration of expert interdisciplinary teams, a trend that has been accelerated by the recent advances in remote collaboration.

9. Use a phased approach to development

No matter the approach you use, site-specific optimization is necessary. The path from concept implementation should include clear phases, decision points, and weighting criteria. If passive, semi-passive, or in situ treatment is used, the development phases can be much longer than expected with active treatment. These semi-passive systems must address variation of conditions through their design, whereas active treatment systems can overcome variability using electricity and reagents. Regardless of the approach taken, a phased approach often uses a path of information gathering, lab/bench testing, pilot testing (on site or in dedicated facilities), field testing, and full-scale implementation. Each phase should be purposeful with specific goals that link directly to full-scale design, commissioning, operation, and adaptive management.

10. Expect to evolve

Even the best made plans will encounter some bumps. The best way to proactively plan for changes in mine water treatment is implementing an adaptive management plan. Bolstered by a failure modes and effects analysis, an adaptive management plan outlines likely outcomes of specific situations and how they will be managed if or when they arise. It is a living document that incorporates the latest data, newest technology, and most recent knowledge which is used to inform decisions. These are often structured with if/then decision trees with clear action thresholds.

How many of these best practices do you have in place for your mine water treatment plan? Whether it is implementing all 10, or making incremental adjustments, with ongoing updates to both operational mine water management and closure strategies throughout a mine life, there’s no shortage of opportunity to begin to make changes.

Dr. Monique Simair is a globally recognized leader in passive and semi-passive water treatment for the mining sector, including bioreactors, constructed wetlands, in situ treatment, and contaminant source control methods. She is the founder and CEO of Maven Water & Environment (www.mavenwe.com) and can be contacted at monique@mavenwe.com.

Comments

Randy Agius

In my many years in the industry and travels around the globe I got to experience how the industry has performed when it comes to protecting the environment. We all have read of the good and the bad and the bad is what typically stands out and makes us all look like the bad guys. It is unfortunate that politics also plays a game in the industry and that one country has different rules than the other. In todays world we all have the know-how and technology to deal with any nasty that comes out from the end product into the environment. So my personnel feeling is if you as a company cannot deal with the issue because the technology is not available or that the project is not feasible to deal with the problem, leave the deposit alone until the day you can.