Small modular reactors

Interview with Ken Darlington, vice-president of corporate development with USNC-Power

A survey by the Canadian Nuclear Association (CNA) found that climate change remains a serious issue if Canada is to achieve its climate goals. There is a strong belief that the government should invest in a mix of renewable and nuclear energy projects.

The federal government released its small modular nuclear reactors (SMR) action plan in December 2020. It explains Ottawa’s role in advancing this technology.

Minister of Natural Resources, Seamus O’Regan, said in a statement, “Small modular reactors represent the next great opportunity for Canada … to phase out coal and electrify carbon-intensive industries such as mining.” SMRs are an attractive option for the replacement of fossil plants or for complementing existing industrial processes or power plants with an energy source that does not emit greenhouse gases. Deployment of advanced SMRs can help drive Canada’s economic growth.

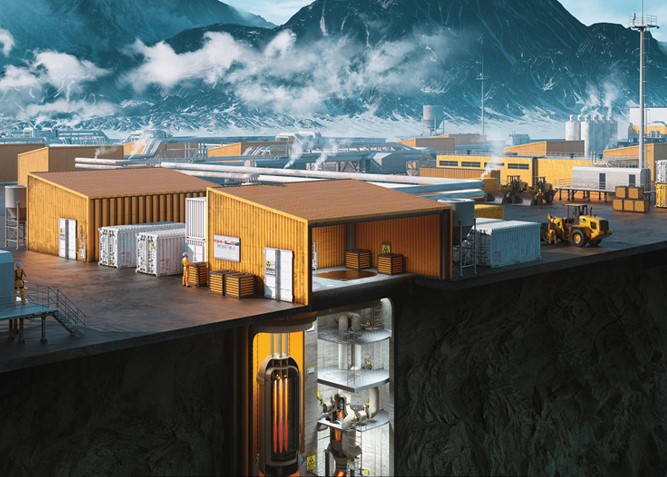

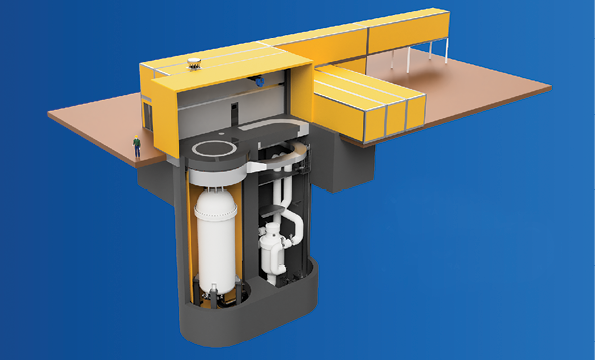

Since 2014, Ultra Safe Nuclear Corporation has been progressing its plans to deploy Canada’s first SMR: a micro modular reactor (MMR). With a joint venture formed and a project host agreement in place to site a reactor at Chalk River laboratories in Ontario, USNC-Power expects the country’s first commercial MMR to be operational in 2027.

A few weeks ago, I interviewed Ken Darlington, vice-president of corporate development with USNC-Power to talk about the recent developments in SMR technology and the company’s MMR.

CMJ: Let us start our conversation by talking a bit about Ultra Safe Nuclear Corporation? What is the difference between Ultra Safe Nuclear Corporation and USNC-Power and what is your role at USNC-Power?

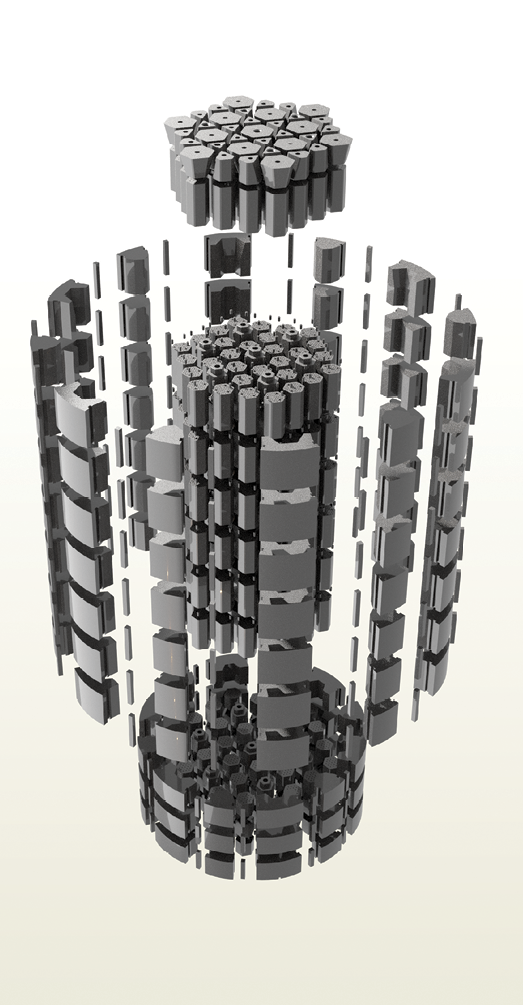

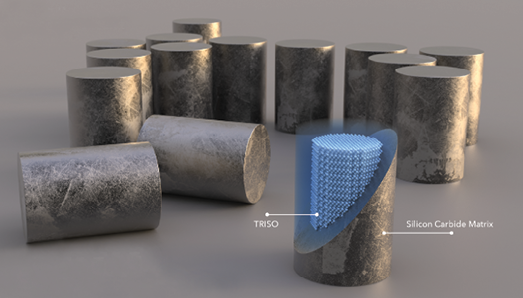

KD: Ultra Safe Nuclear Corporation is the parent company: a Seattle-based global leader in the deployment of micro reactors with its Canadian operations (USNC-Power) headquartered in Ottawa, Ont. Ultra Safe Nuclear is an integrator of nuclear power technologies, committed to bringing safe, commercially competitive, clean, and reliable nuclear energy to global markets. Ultra Safe Nuclear Corporation’s MMR energy system can provide electricity or process heat to heavy industries and remote communities. Also, Ultra Safe Nuclear Corporation developed its proprietary nuclear fuel: fully ceramic micro-encapsulated fuel (FCM). USNC-Power will be deploying the MMRs into the Canadian market.

For over 20 years, my career has been in engineering and construction in the mining industry. I have been with USNC-Power for two years. I ended up working with a nuclear power company to build that bridge between the nuclear power industry and the resource sector. Decarbonization is a strategic priority for all major mining companies, and even the smaller ones have aggressive net-zero targets. I am a mining guy at heart, and I wanted to be a part of an effective solution because decarbonization of the mining industry is now front and center.

CMJ: Can you explain what is an MMR?

KD: The MMR is a new class of nuclear reactors; it is much smaller in size and power than any traditional nuclear reactors with enhanced safety features. Factory constructed with a far smaller footprint and expected economies from fleet operation, the MMR is suitable for powering remote communities and providing process heat to industry and is expected to be operational in Canada later this decade. Our reactor is designed to provide a solution specifically for off-the-grid applications. The size of our reactor is suitable to the Canadian market, particularly in the resources sector (mines) and remote communities. In some cases, it can serve both a mine and its local community, which is a double benefit.

CMJ: Can you summarize in general the benefits of your MMR? How is your MMR different from any other SMR technology? What makes it unique and more suitable for the Canadian mining industry and other applications?

KD: Canada has a resource-based economy. Securing the energy and having cost certainty for the life of mine is what nuclear power can provide that can help de-risk the economics of a project. Companies sometimes need to fly diesel in or bring it on ice roads to remote mines. Who knows if the ice road will still be there in 10 years? So, it is the risk in addition to the cost of the carbon tax.

In the last two years, I have seen a shift in the mining sector with respect to how they are assessing technologies. A year ago, the word “nuclear” would not even be mentioned in net-zero conferences: “Let us find any solution and avoid anything that may be a difficult topic to address socially.”

During the CIM conference in Vancouver, there was a discussion about how small modular reactors are now a valid option for the mining companies. It is not about one technology or the other; it is about leveraging all technologies, collaborating across technologies, and using everything we have got to reach the net-zero target.

We view nuclear energy as green energy. There is no one perfect solution; all renewables have their own footprint and challenges as well. Nuclear power is a reliable source of energy that has a very low carbon footprint. So, it brings that base load energy that you can complement with renewables.

Generally, SMRs offer a lower initial capital investment, greater scalability, and flexibility to be used in locations unable to accommodate more traditional larger reactors. They also have the potential for enhanced safety and security compared to earlier designs. The cost of power or diesel can be deal breakers for certain projects. That is another motivation to switch to a clean, robust source of energy for mining in Canada.

The unique feature of MMRs is their reliability over any other kind of energy source.

Solar and wind, for instance, are also reliable, but there is a practical limitation to how much energy you can get from them depending on the location. The sun does not always shine, and the wind does not always blow. Batteries can store some of that energy, and in smaller applications that may work. However, it will be difficult to sustain the load for a mine that needs 5, 10, or 20 MW. We do not see it as one technology versus the other; they can be complementary to each other.

Also, SMRs can be coupled with other energy sources: renewables or even fossil energy to leverage resources and produce higher efficiencies and multiple energy end-products while increasing grid stability and security. Our advanced MMR design can produce a higher temperature process heat for either electricity generation or other mining and industry applications.

SMRs can provide power for applications where large plants are not needed or sites lack the infrastructure to support a large unit, including smaller electrical markets, remote areas, smaller grids, and other unique industrial applications. There are a few moving parts in the world of SMRs. First, there is a spectrum in size; anything under 300 MW (specifically between five and 300 MW) is considered an SMR. Since we are looking at off-grid applications, one of the advantages of the MMR is its small size that makes it suitable for deployment at mines and in remote communities.

MMRs can produce five MW for 20 years continuously; you do not need to refuel the reactor. These are very small plants, and we refer to them more as batteries. A single reactor is the size of a tanker truck. If you need 20 MW, you put in four reactors and so on. Now, you have a single power plant that can secure the process heat and electricity for the life of the mine.

MMRs do not produce electricity; they produce heat, and you decide what you want to do with that heat. The potential deployment of an MMR at a mine campus will demonstrate how a community reactor can provide energy for all facets of life. We can use the heat to provide carbon-free electrification of mobile fleet process, heating, and agricultural use for the community.

Currently, our MMR is the only SMR project in Canada in formal licensing process with the Canadian Nuclear Safety Commission, which gives us a significant lead in terms of time to market. The reactor at Chalk River is the same design intended for commercialization. For a mining project or a remote community, since the design has already been through the licensing process, it will be familiar to the regulator.

CMJ: McMaster University, Ultra Safe Nuclear, and GFP entered a new partnership to advance research in SMRs. Can you talk in detail about the recent MOU and how it will help Canada reach a low-carbon future?

KD: We partnered to drive SMR research, innovation, and training. All partners in this agreement are expected to use their knowledge and expertise to help Canada meet its net-zero target.

Mining is a big industry and the same can be said for the nuclear power industry. I would say one thing that is different in working for a technology company is the necessity of forming effective partnerships so that you can leverage that technology. In our case, we partnered with GFP to develop Canada’s first MMR at Chalk River laboratories. GFP is developing Canada’s first commercial SMR at the Chalk River laboratories site, where much of the research and training will take place. We signed an MOU to further examine the feasibility of deploying the MMR at McMaster University or an affiliated site. McMaster is a global leader in nuclear R&D and a recognized centre of excellence for training.

Ultra Safe Nuclear has developed the MMR technology for worldwide deployment. GFP is the partnership between USNC-Power and Ontario Power Generation (OPG) that is deploying Ultra Safe Nuclear’s MMR technology in Canada.

This is the most advanced SMR project in the Western world, and McMaster’s talent pool of experts, building research collaborations and fostering student training initiatives will strengthen the position of Canada as a global leader in SMR deployment which is critical for addressing the global climate emergency. GFP’s MMR Project at Chalk River is expected to be operational in 2027.

Ultra Safe Nuclear’s CEO, Francesco Venneri, believes the GFP’s MMR project is specifically designed for Canadian climates, and similar in size and power to McMaster’s five-MW reactor.

CMJ: So, it is a win-win situation for them and for everybody; were those efforts in response to the announcement of Canada’s SMR action plan?

KD: SMRs are gaining momentum very fast in Canada. Canada is going to need research and training and several other things to develop a national SMR industry, and McMaster are seeking to be leader of that in the academic space. Canada’s SMR action plan lays out Ottawa’s role in advancing the technology. The plan is the result of a pan-Canadian effort bringing together key enablers from across Canada: the federal government, provinces and territories, Indigenous Peoples and communities, power utilities, industry, innovators, laboratories, academia, and civil society. Both Ultra Safe Nuclear and OPG are contributors to Canada’s SMR action plan. The partnership also builds on McMaster’s rich nuclear expertise and contributions to Canada’s SMR action plan. It also allows Ultra Safe Nuclear to conduct life-cycle studies on the optimal utilization of SMRs and train the next generation of experts that will build, operate, maintain, monitor, and regulate these facilities. The government believes SMRs could be the solution to provide clean energy to remote mining and fossil fuel projects in need of power.

CMJ: Most of the mining sites in Canada are within First Nations’ territories. Your technology will help to improve the quality of life in those remote communities. Do you expect problems in deploying the technology to Indigenous territories knowing that it is nuclear power?

KD: Canada has a lot to gain by pursuing SMRs reactors, and powering remote communities is just a part of that. There is an Indigenous advisory council on Canada’s SMR action plan. So, they are engaged at the national level.

Now is the time for those discussions with Indigenous communities because we are looking at commercialization of our MMR reactor in 2027, so it makes sense to start engaging Indigenous communities now. GFP has been engaged with Indigenous communities in the Chalk River project and has agreements with five of them. Indigenous engagement must start before day one. Recently, I attended a First Nations Power Authority conference in Saskatoon, and the number one priority for mining companies is to engage those communities.

There is no mining project and without Indigenous support, there is no nuclear project either. We need to listen to and understand their concerns.

Our technology can provide a reliable solution for the economic prosperity of those communities, and it offers an opportunity for the mining companies to participate in securing the energy for those communities. The logistics of using diesel is also a risk to those communities, and an MMR unit running for 20 years without refueling replaces 200 million litres of diesel.

USNC-Power and Global First Power (GFP) entered a strategic partnership with McMaster University to advance research in SMRs technology (a clean energy technology that will play an essential role in Canada’s net-zero by 2050 goal) at the university while testing to implement in remote communities and select industries. The memorandum of understanding (MOU) with McMaster demonstrates the continued advancement of nuclear energy in the country and paves the way for Canadian communities to adopt an original approach to greenhouse gas-free energy.

Comments